High-performance marine climate resistant steel plate and manufacturing method thereof

A marine climate and steel plate technology, applied in the field of high-performance marine weather-resistant steel plates and their manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0065] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

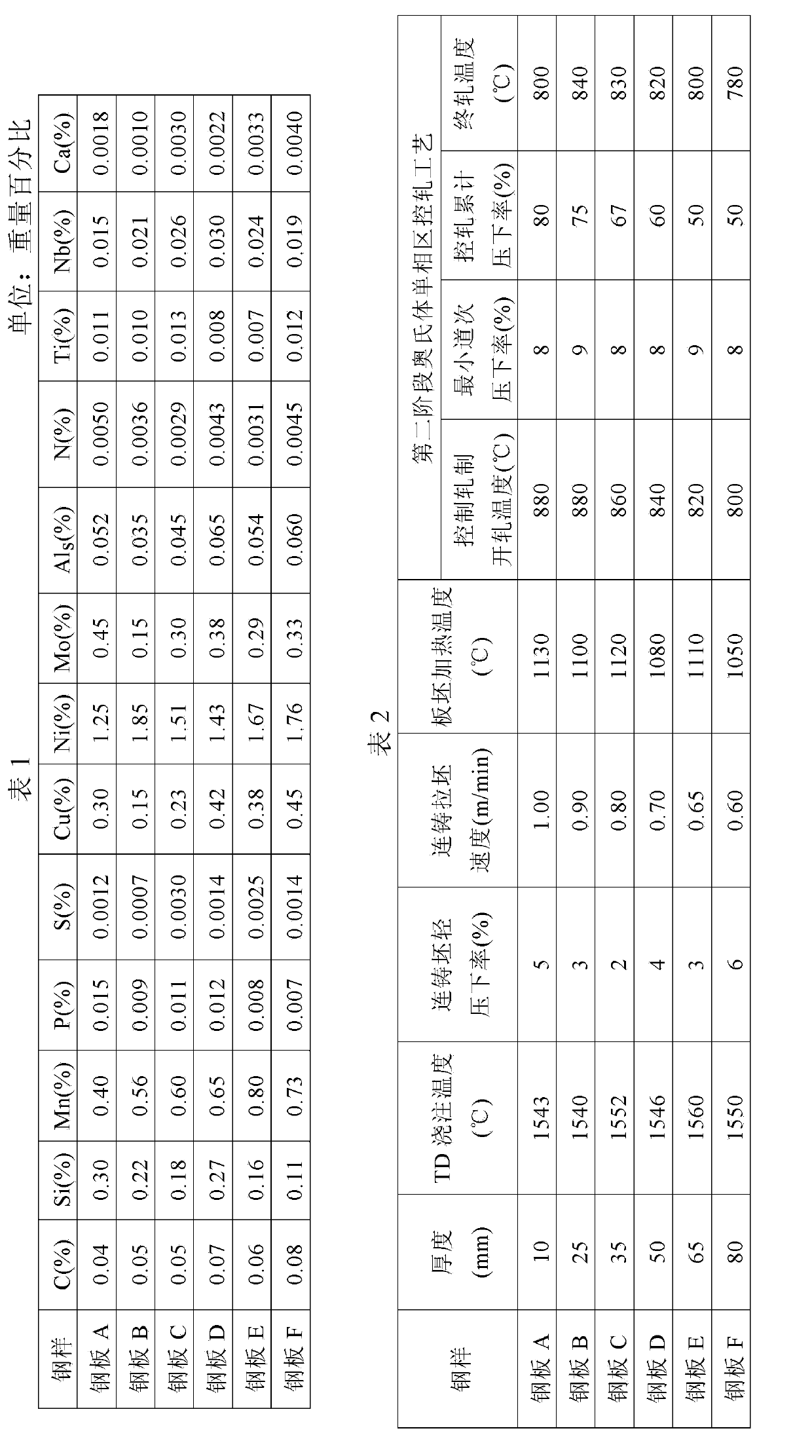

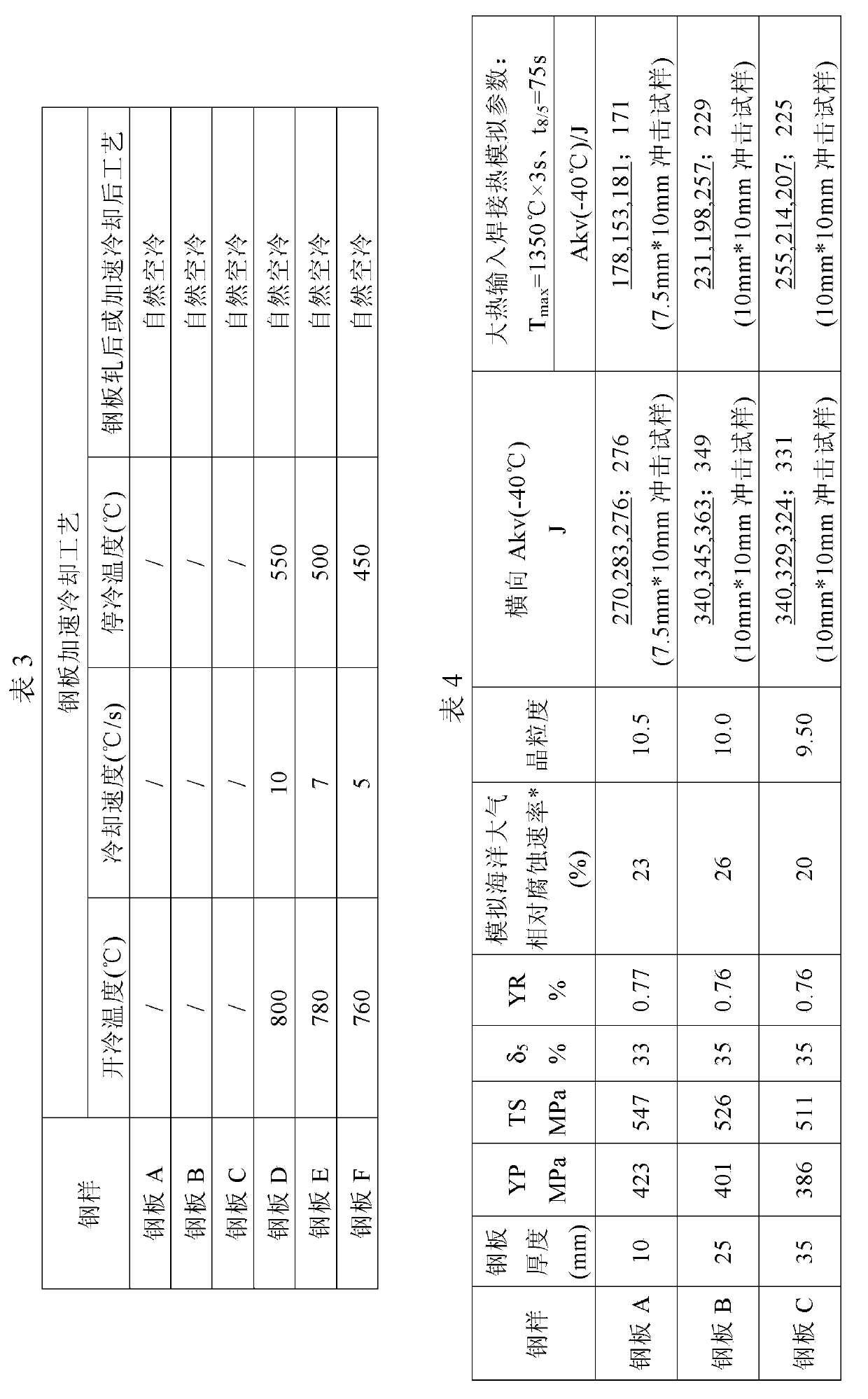

[0066] Table 1 shows the composition of the steel example of the present invention, Table 2 and Table 3 show the manufacturing process of the example of the present invention, and Table 4 shows the properties of the steel of the example of the present invention.

[0067] The manufacturing process flow of the embodiment of the present invention is: deep desulfurization of TDS molten iron → converter smelting → LF → RH (feeding Si-Ca wire) → continuous casting (using light reduction process) → slab off-line finishing → slab size heating Cutting→heating→normalizing rolling or TMCP→steel plate natural air cooling→AUT / MUT→steel edge trimming, head and tail cutting→sampling and performance inspection→cutting to length steel plate→surface quality and appearance size, marking and testing→delivery.

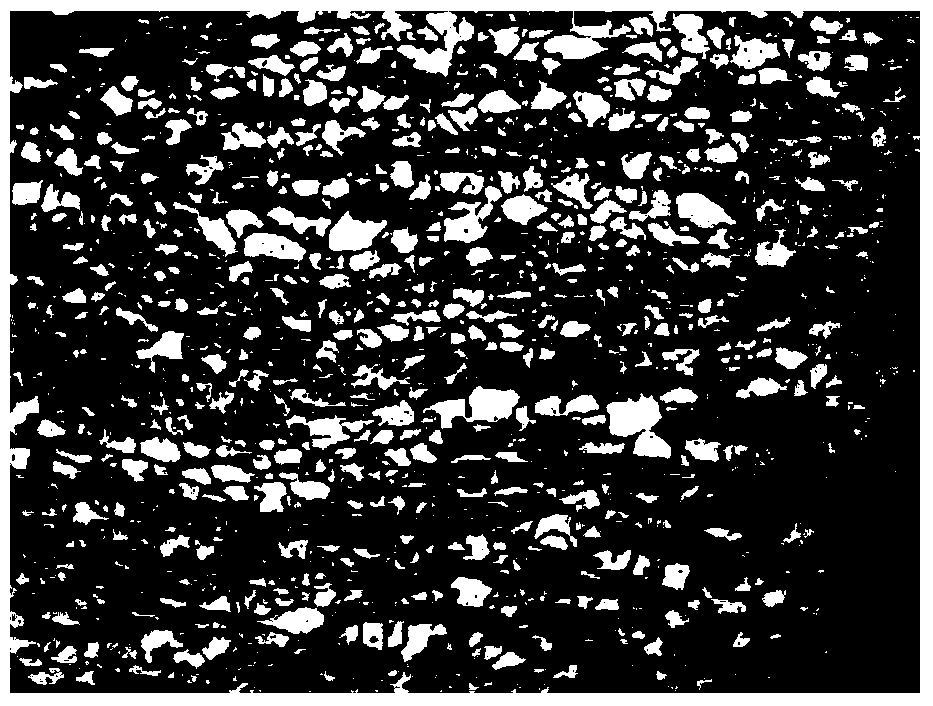

[0068] Depend on figure 1 It can be seen that the microstruct...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield ratio | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com