Method for preparing nano copper conductive ink

A conductive ink and nano-copper technology, which is applied to conductive materials, inks, household appliances, etc. dispersed in non-conductive inorganic materials, can solve the problems of complex preparation process, high heating temperature, and long preparation period, and achieve particle dispersibility. Good, good dispersion, low production cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 10 mmol CuCl 2 .2H 2 O and 2.6 grams of polyvinylpyrrolidone (PVP) were dissolved in 50 milliliters of deionized water respectively, mixed and stirred, and the temperature was raised to 80° C., and an amount of ammonia was added to adjust its pH value to 10; 5 milliliters of 50% hydrazine hydrate solution was slowly added dropwise, and Stir for 60 minutes and cool to room temperature to obtain a nano-copper dispersion; centrifuge the obtained copper dispersion at a speed of 8000 rpm for 15 minutes, wash twice with deionized water and absolute ethanol, and then vacuum at room temperature Dry for 2 hours to obtain nano-copper particles; weigh 0.4 g of nano-copper particles, dissolve in 0.6 g of diethylene glycol monobutyl ether, and obtain nano-copper conductive ink with a solid content of 40% after ultrasonication for 15 minutes.

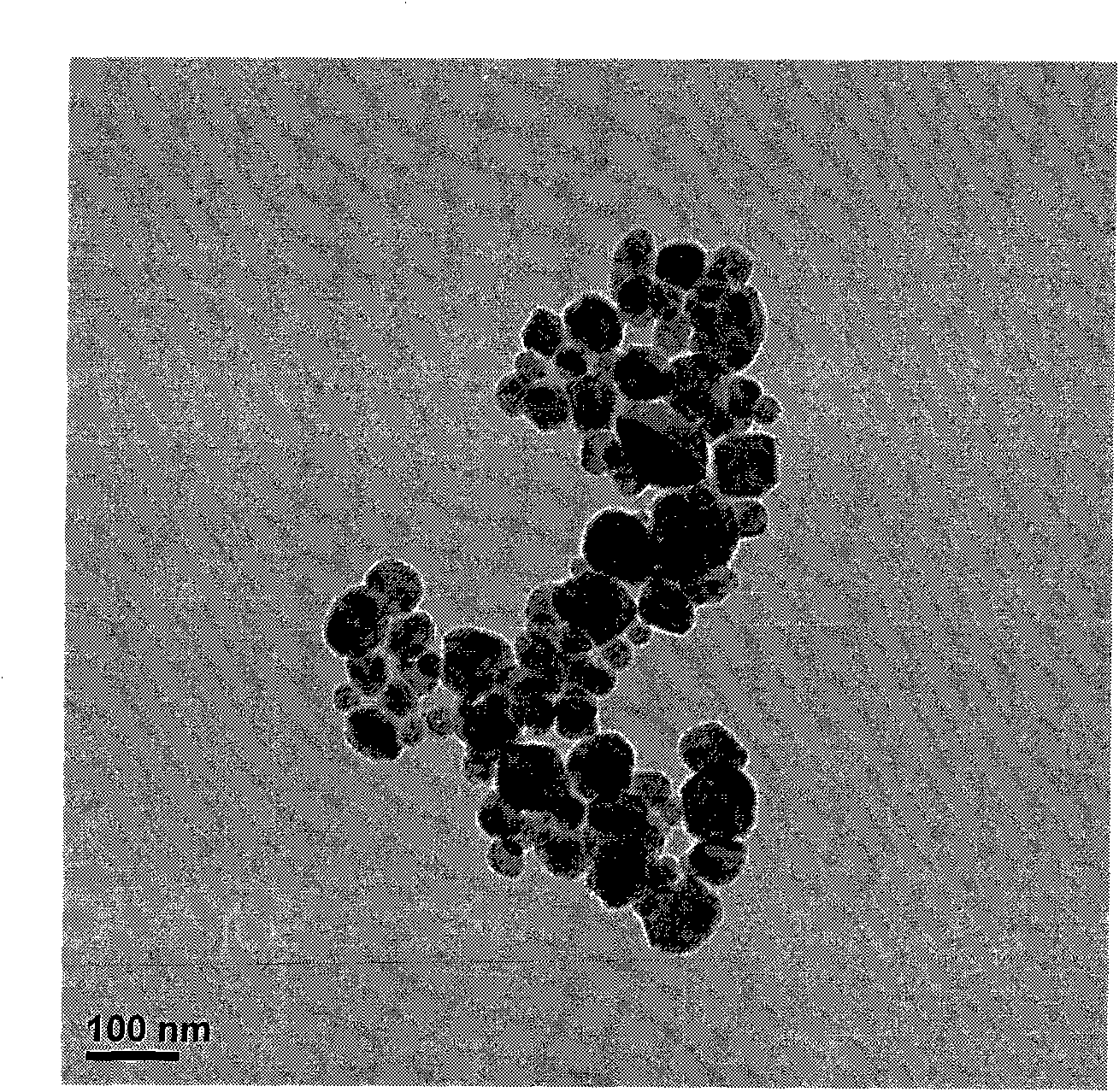

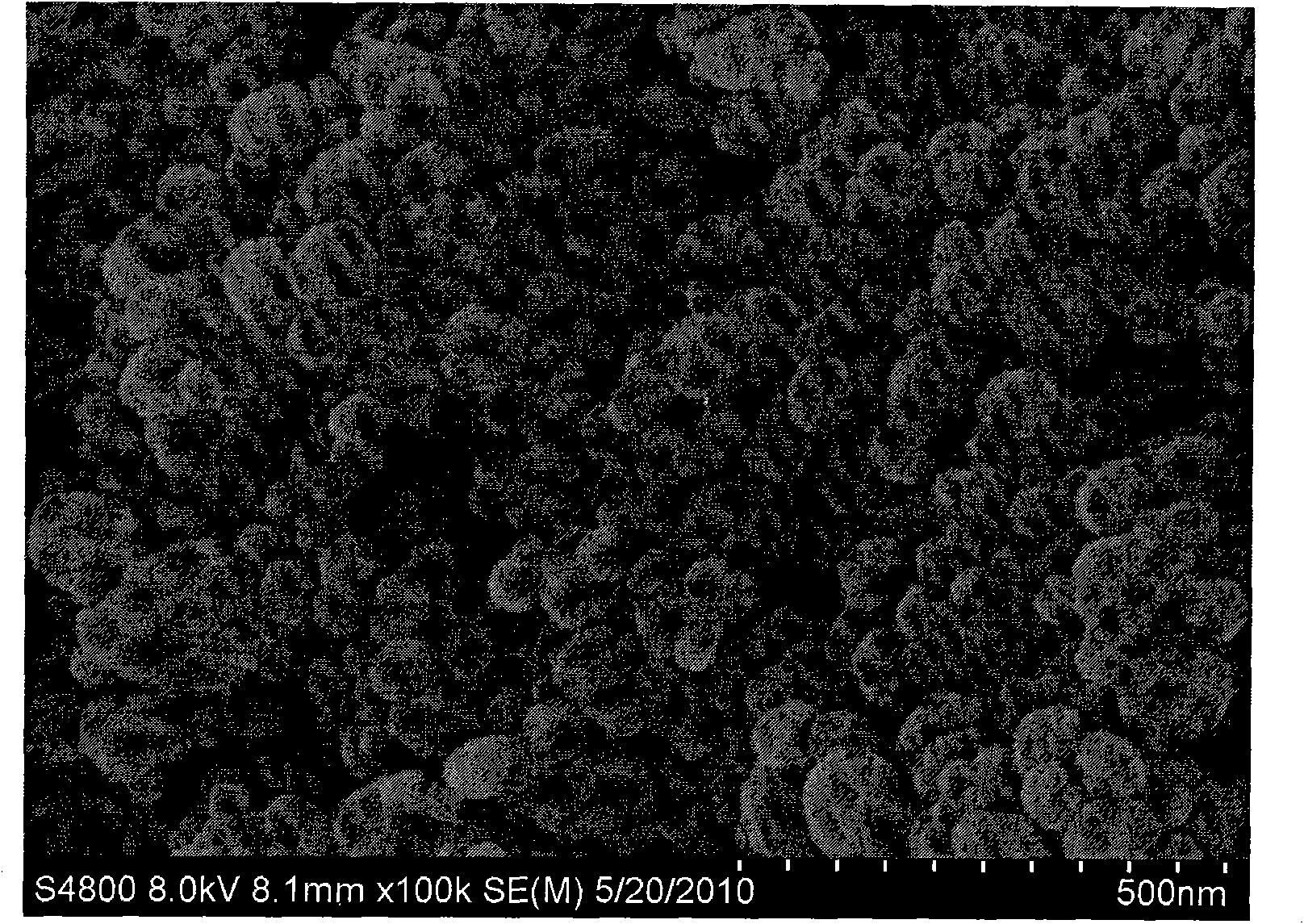

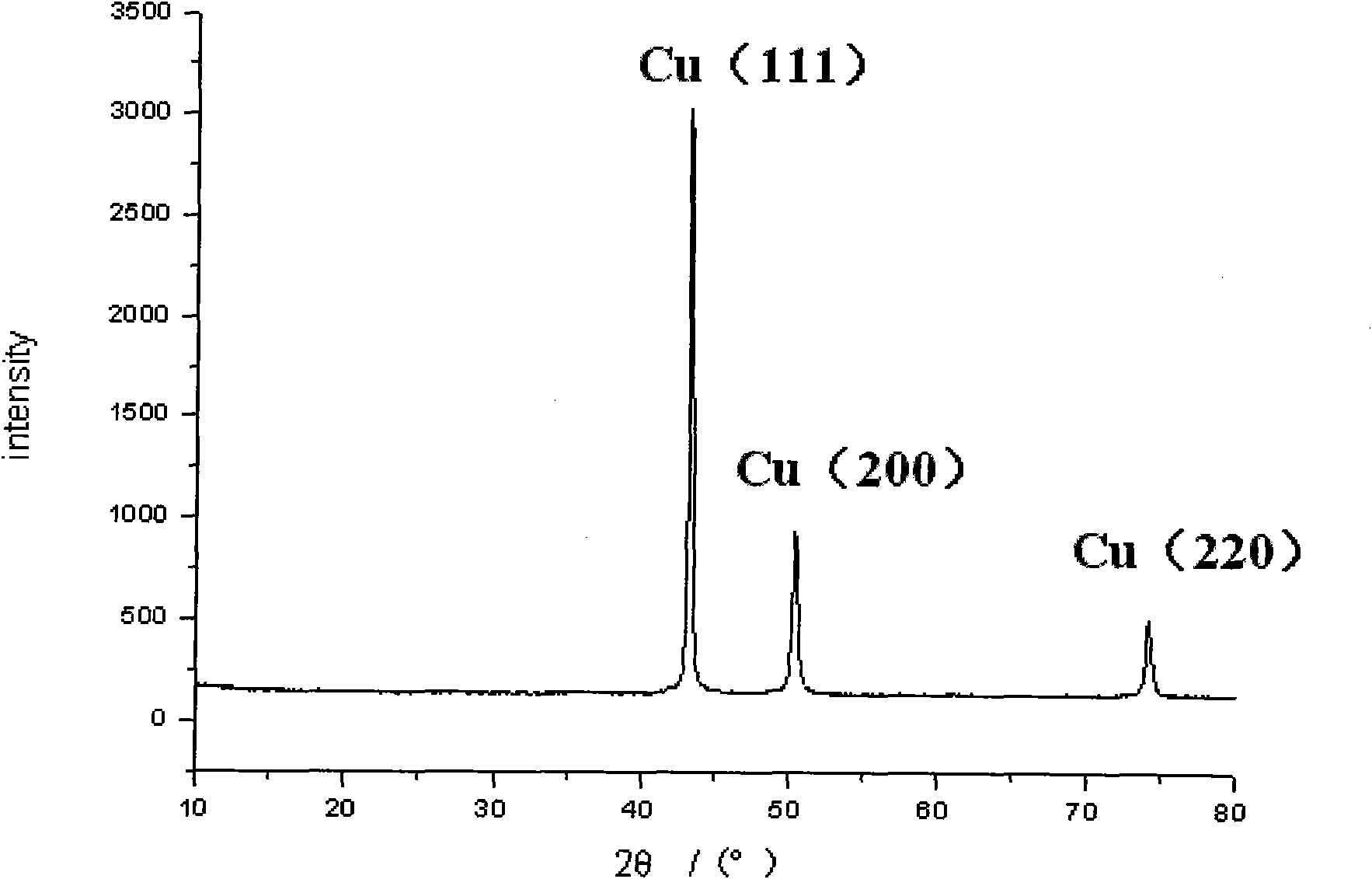

[0029] The nano-copper conductive ink obtained above is sampled, and the copper particles in the nano-copper conductive ink are observed usi...

Embodiment 2

[0031] 10 mmol CuSO 4 5H 2O and 1.62 grams of polyacrylamide were respectively dissolved in 50 milliliters of ethylene glycol and 50 milliliters of deionized water, mixed and stirred, heated to 80 ° C, and an appropriate amount of ammonia water was added to adjust its pH value to 9; 5 milliliters of 50% hydrazine hydrate solution was slowly added dropwise , continuously stirred for 30 minutes, cooled to room temperature to obtain a nano-copper dispersion; the obtained copper dispersion was centrifuged at a speed of 8000 rpm for 15 minutes, washed twice with deionized water and absolute ethanol, and then heated at room temperature Dry under vacuum for 2 hours to obtain nano-copper particles; weigh 0.2 g of nano-copper particles, dissolve in 0.8 g of ethylene glycol butyl ether, and obtain nano-copper conductive ink with a solid content of 20% after ultrasonication for 15 minutes.

[0032] The TEM figure, SEM figure and XRD figure of this nano copper conductive ink are similar ...

Embodiment 3

[0034] 10 mmol CuCl 2 .2H 2 O and 2.6 grams of polyvinylpyrrolidone (PVP) were respectively dissolved in 50 milliliters of diethylene glycol, mixed and stirred, heated to 30 ° C, and an appropriate amount of ammonia was added to adjust its pH to 7; slowly dropwise added 5 milliliters of 50% hydrated Hydrazine solution, continuously stirred for 60 minutes, cooled to room temperature to obtain a nano-copper dispersion; the obtained copper dispersion was centrifuged at a speed of 8000 rpm for 20 minutes, washed twice with deionized water and absolute ethanol, and then Vacuum-dry at room temperature for 3 hours to obtain nano-copper particles; weigh 0.3 g of nano-copper particles and dissolve in 0.7 g of diethylene glycol monobutyl ether, and obtain nano-copper conductive ink with a solid content of 30% after ultrasonication for 15 minutes.

[0035] The TEM figure, SEM figure and XRD figure of this nano copper conductive ink are similar to those in Example 1 figure 1 , figure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com