Bio-based artificial quartz stone and production process thereof

An artificial quartz stone, bio-based technology, applied in the direction of manufacturing tools, ceramic molding machines, etc., can solve the problems of environmental pollution, seldom effectively used, etc., to reduce environmental pollution problems, excellent resistance to ultraviolet light aging, and reduce costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

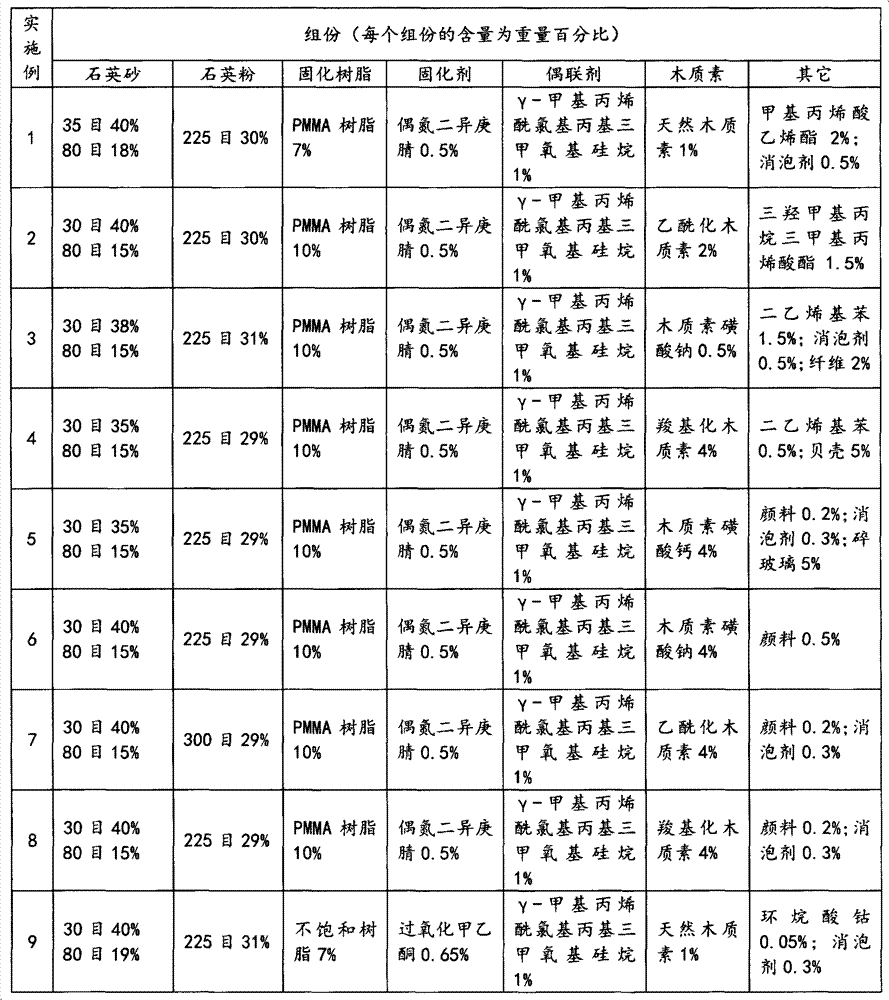

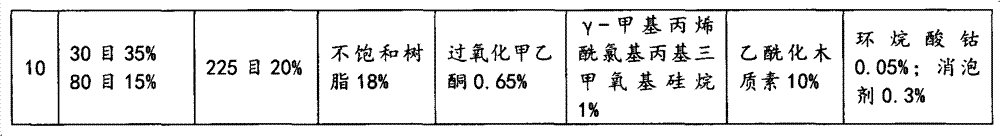

Examples

Embodiment 1 to 8

[0057] Embodiment 1 to 8 adopts following method to prepare artificial quartz stone:

[0058] At first, prepare cured resin, dissolve the PMMA of 25 parts by weight in the MMA monomer of 75 parts by weight, stir until dissolving; Then, according to the component proportioning that provides in the embodiment, add each component in the vacuum mixer, Stir and mix for 10-20 minutes under negative pressure with a vacuum degree of -0.05~-0.06MPa, then transfer the mixture to a vacuum press, and then make the vacuum degree reach -0.05~-0.06MPa, heat and vibrate under vacuum After 30 minutes of initial curing, keep the ambient temperature of the mold at 70-80°C during the process, then put the mold in an oven, and cure it at 130°C for 80 minutes; finally, take off Molding, thickness setting, polishing and cutting to make finished products.

Embodiment 9~10

[0060] According to the composition ratio given in the examples, add lignin powder, quartz sand, quartz powder, unsaturated resin, coupling agent, curing agent, accelerator, crosslinking agent, pigment, etc. into the mixer and stir and mix for 10 minutes , then transfer the mixture to a vacuum press, then evacuate to -0.09~-0.095Mpa, vibrate and compact under vacuum, press at room temperature for 10 minutes, then put it in an oven, raise the ambient temperature to 50°C for curing After 30 minutes, continue to raise the ambient temperature to 130°C, release the mold after curing for 80 minutes, and then cut to a thickness to obtain a finished product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com