Humic acid coated urea and production method thereof

A technology of coating urea and humic acid, which is applied in the fields of agricultural gas emission reduction, fertilizer mixture, fertilization equipment, etc., can solve the problem of large-scale production and sales of humic acid-coated urea products, the inability to carry out subsequent processing, and the difficulty of large-scale production. Large-scale production and other issues, to achieve the effect of abundant reserves, improved urea utilization rate, and easy promotion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] Urea specifications: particle size 2.00 ~ 4.75 mm,

[0076] Adhesive composition:

[0077] Styrene-acrylic waterproof emulsion (45%): 75 parts by weight, polyvinyl formal resin (8%): 10 parts by weight, yellow dextrin: 5 parts by weight, water: 10 parts by weight.

[0079] Humic acid (180-300 mesh): 45 parts by weight, sodium humate (120-200 mesh): 15 parts by weight, hemihydrate gypsum (180-300 mesh): 20 parts by weight, calcined diatomite (180-325 mesh ): 8 parts by weight, sodium-based pentonite (160-200 mesh): 4 parts by weight, sodium polyacrylate (160-200 mesh): 6 parts by weight, dicyandiamide (160-200 mesh): 2.0 parts by weight.

[0080] Urea consumption: 90KG

[0081] Adhesive dosage: 1.5KG

[0082] Package powder consumption: 8.5KG

[0083] Follow the steps below:

[0084] (1) Put the binder raw material into the blending tank, mix it with water, and make the binder for subsequent use;

[0085] (2) Mixing humic acid and ...

Embodiment 2

[0091] The urea specification, binder composition, package powder proportioning are the same as embodiment 1

[0092] Urea consumption: 86KG

[0093] Adhesive dosage: 2.0-KG

[0094] Package powder consumption: 12.0KG

[0095] According to embodiment 1 step operation

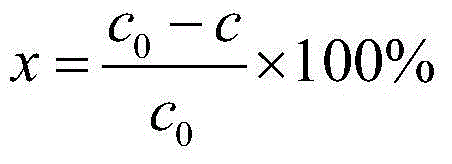

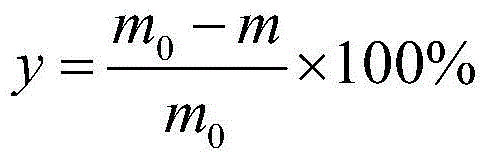

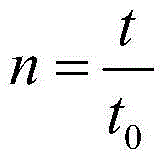

[0096] After testing, the relative loss control rate of the obtained humic acid-coated urea is 76%, the relative water retention rate is 77%, and the slow dissolution rate is 4.3 times.

Embodiment 3

[0098] The urea specification, binder composition, package powder proportioning are the same as embodiment 1

[0099] Urea consumption: 82KG

[0100] Adhesive dosage: 2.5KG

[0101] Package powder consumption: 15.5KG

[0102] According to embodiment 1 step operation

[0103] After testing, the relative loss control rate of the obtained humic acid-coated urea is 86%, the relative water retention rate is 82%, and the slow dissolution rate is 5.1 times.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com