Cyanide-free bright electrogilding additive and application thereof

A bright electroplating and inorganic additive technology, applied in the field of electroplating gold, can solve the problems of narrow process range, low stability of plating solution, poor coating quality, etc., and achieve the effect of uniform appearance, excellent performance and improved coating performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0015] Embodiment 1: The cyanide-free bright electroplating gold plating additive in this embodiment is one or more organic additives, or a mixture of one or more inorganic additives and organic additives.

[0016] The electroplating gold process operation is as follows:

[0017] 1. Additive preparation: Weigh one or more inorganic additives and organic additives, or one or more organic additives, and use ultrapure water to prepare a clear solution, store at constant volume, and obtain the solution of the electroplating gold additive. The prepared plating solution is prepared by ultrapure water with a resistivity of 18MΩ / cm, and the concentration of each component of the additive in the solution is 0.5-30g / L. The main purpose of the electroplating gold additive in this system is to realize that the performance of the plating solution and coating can be comparable to that of the cyanide electroplating gold system.

[0018] 2. Preparation of electroplating gold plating solution...

specific Embodiment approach 2

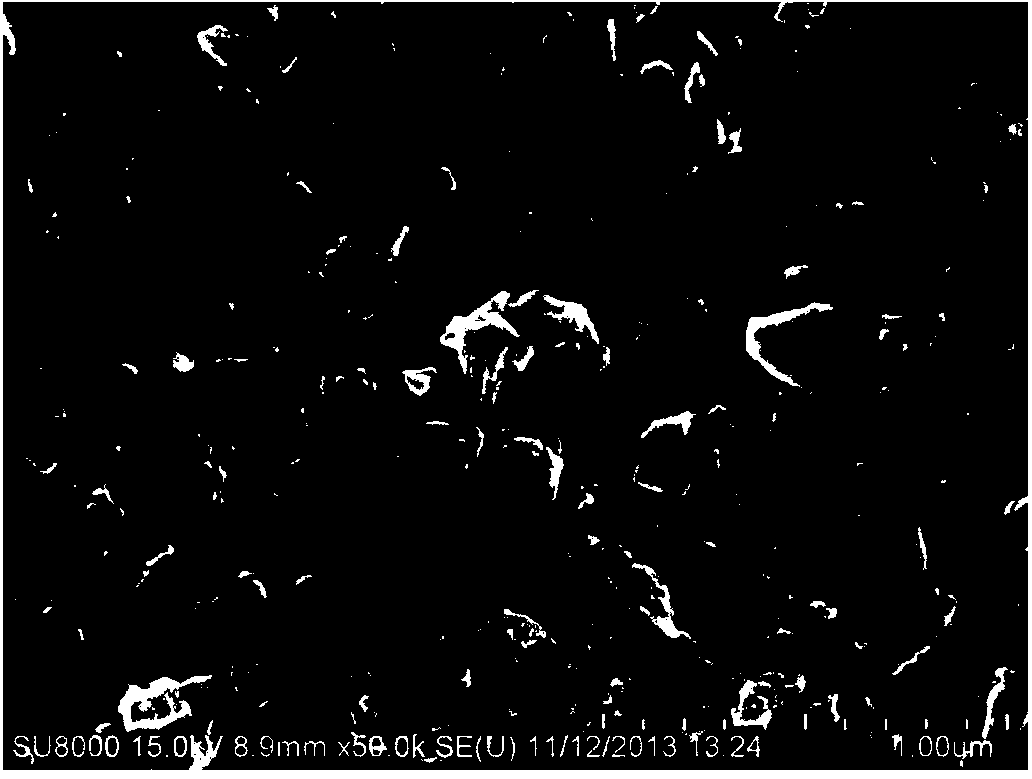

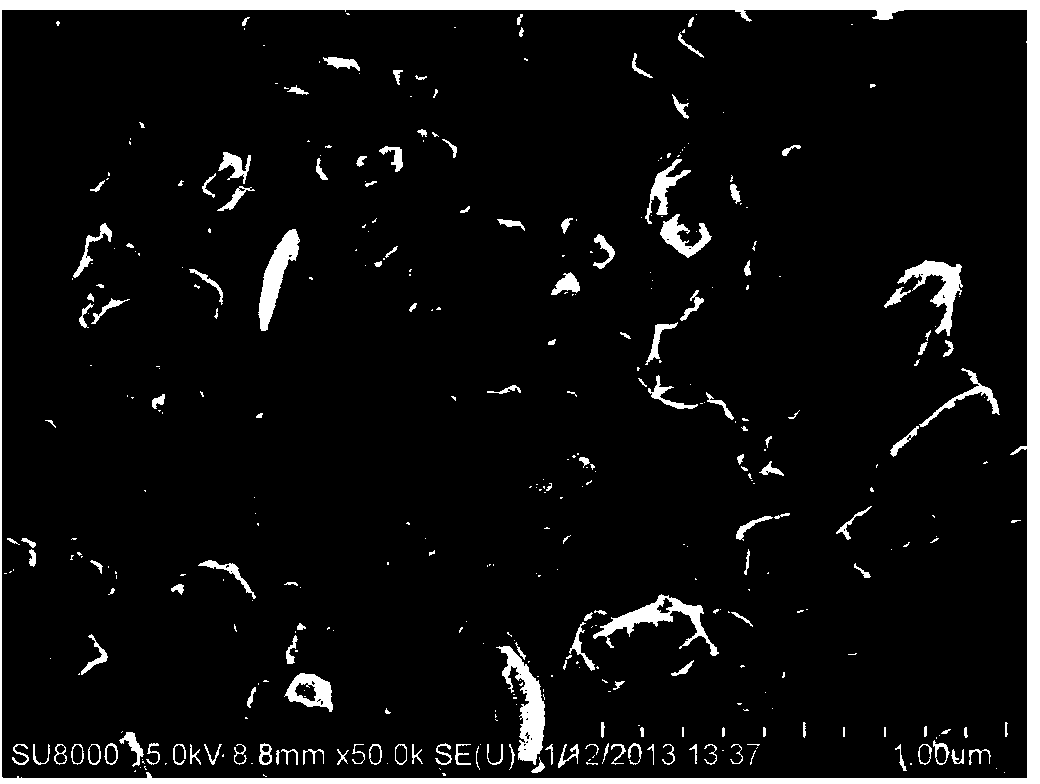

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is that the concentration of each component in the electroplating gold additive is: antimony potassium tartrate 10g / L, polyethylene glycol 5g / L, guanine 5g / L , 5g / L of succinimide, and the amount of additives in electroplating gold is 0.5mL / L. The appearance of the coating obtained in the bath without additives is not bright, and the crystals are relatively coarse. The coating obtained in the bath containing additives is uniform and flat, golden and bright, and the microscopic crystals are uniform, small, flat and dense, and free of cracks by SEM observation. The SEM images of the electroplated gold coating obtained by the plating solution without additives and the plating solution after adding additives are as follows figure 1 with figure 2 shown.

specific Embodiment approach 3

[0024]Specific embodiment three: the difference between this embodiment and specific embodiment two is that the concentration of each component in the described electroplating gold additive is: use potassium selenite 5g / L, saccharin 10g / L, 1,4-butyne Glycol 5g / L, sodium lauryl sulfate 1g / L prepare electroplating gold additives, the amount of additives in electroplating gold is 10mL / L, the obtained coating is macroscopically uniform and smooth, golden and bright, and the microscopic crystals are uniform, small and smooth under SEM observation Dense, no cracks.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com