Curing sintering-free granulation method for sludge

A treatment method and sludge technology, which is applied in the field of environmental engineering waste treatment and water conservancy engineering materials, can solve the problem that sludge is difficult to be directly used as engineering materials, and achieve the effect of high solidification efficiency and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

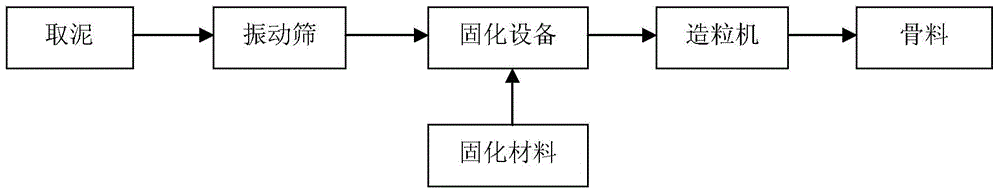

Method used

Image

Examples

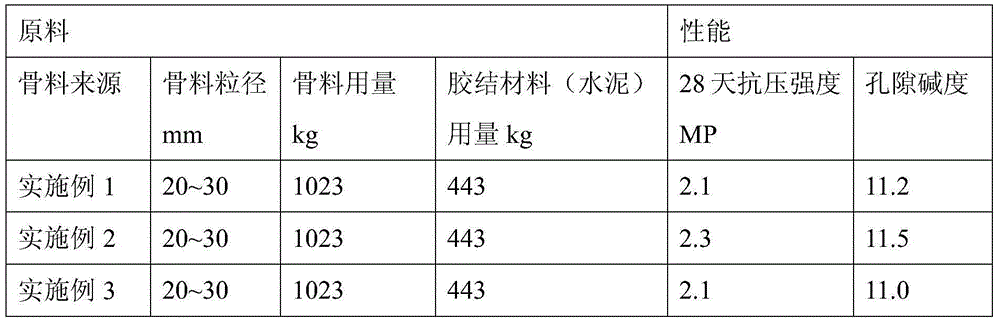

Embodiment 1

[0025] The first step: use pumps and pipelines to obtain the bottom sludge;

[0026] Step 2: Use a vibrating filter screen to pretreat the sludge, separate the solid waste such as plants and stones, and the remaining sludge enters the next section of the processing unit;

[0027] The third step: use the pipeline to input the water-containing sludge to the curing equipment, and spray the curing material; in the curing material, the addition amount of each component is: Portland cement 350kg / m 3 Silt, fly ash 175kg / m 3 , Phosphogypsum 35kg / m 3 ; Then add 105kg / m of steel slag with a particle size of 1-5mm 3 mix;

[0028] Step 4: Use a granulator to make the solidified silt into aggregates in the shape of stones or pebbles.

Embodiment 2

[0030] The first step: use pumps and pipelines to obtain the bottom sludge;

[0031] Step 2: Use a vibrating filter screen to pretreat the sludge, separate the solid waste such as plants and stones, and the remaining sludge enters the next section of the processing unit;

[0032] The third step: use the pipeline to input the water-containing sludge to the curing equipment, and spray the curing material; in the curing material, the addition amount of each component is: Portland cement 350kg / m 3 , fly ash 175kg / m 3 , desulfurized gypsum 35kg / m 3 ; Then add 175kg / m of slag with a particle size of 1-5mm 3 mix;

[0033] Step 4: Use a granulator to make the solidified silt into aggregates in the shape of stones or pebbles.

Embodiment 3

[0035] The first step: use pumps and pipelines to obtain the bottom sludge;

[0036] Step 2: Use a vibrating filter screen to pretreat the sludge, separate the solid waste such as plants and stones, and the remaining sludge enters the next section of the processing unit;

[0037] The third step: use the pipeline to input the water-containing sludge to the curing equipment, and spray the curing material; in the curing material, the addition amount of each component is: Portland cement 500kg / m 3 , fly ash 250kg / m 3 , Phosphogypsum 60kg / m 3 ; Then add 150kg / m of slag with a particle size of 1-5mm 3 mix;

[0038] Step 4: Use a granulator to make the solidified silt into aggregates in the shape of stones or pebbles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com