Phosphating solution for drawing of low-carbon and medium-carbon steel wire rod

A technology of low carbon steel and phosphating liquid, applied in the direction of metal material coating process, etc., can solve the problem of unstable bonding strength of phosphating liquid and medium and low carbon steel wire rod, poor thermal resistance of phosphating film, unsuitable for high speed Drawing and other problems, to achieve the effect of good thermal adhesion resistance, good environmental protection performance, and firm adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

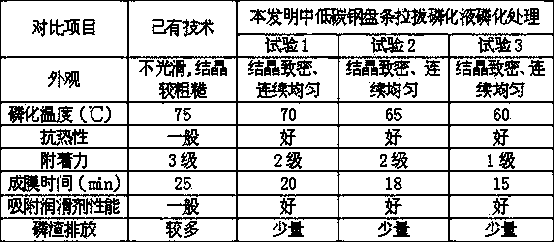

Examples

Embodiment 1

[0025] A kind of medium and low carbon steel wire rod drawing phosphating solution, its raw material composition is:

[0026] Zinc dihydrogen phosphate 17g / L

[0028] Sodium chlorate 1.5g / L

[0029] Sodium nitrite 2.5g / L

[0030] Potassium permanganate 1g / L

[0031] Tartaric acid 5g / L

[0032] water balance

[0033] The above-mentioned medium and low carbon steel wire rod drawing phosphating solution is obtained through the following steps:

[0034] (1) Add zinc dihydrogen phosphate and zinc nitrate to water accounting for 30% of the usage, and stir evenly;

[0035] (2) Add sodium chlorate, sodium nitrite, potassium permanganate, and tartaric acid to the mixture obtained in step (1), stir evenly, add the remaining water to constant volume to obtain the drawn medium and low carbon steel wire rod Phosphating solution.

Embodiment 2

[0037] A kind of medium and low carbon steel wire rod drawing phosphating solution, its raw material composition is:

[0038] Zinc dihydrogen phosphate 11g / L

[0039] Zinc nitrate 26g / L

[0040] Sodium chlorate 1g / L

[0041] Sodium nitrite 3g / L

[0042] Potassium permanganate 2g / L

[0043] Tartaric acid 8g / L

[0044] water balance

[0045] The above-mentioned medium and low carbon steel wire rod drawing phosphating solution is obtained through the following steps:

[0046] (1) Add zinc dihydrogen phosphate and zinc nitrate to water accounting for 55% of the usage, and stir evenly;

[0047] (2) Add sodium chlorate, sodium nitrite, potassium permanganate, and tartaric acid to the mixture obtained in step (1), stir evenly, add the remaining water to constant volume to obtain the drawn medium and low carbon steel wire rod Phosphating solution.

Embodiment 3

[0049] A kind of medium and low carbon steel wire rod drawing phosphating solution, its raw material composition is:

[0050] Zinc dihydrogen phosphate 23g / L

[0051] Zinc nitrate 16g / L

[0052] Sodium chlorate 1g / L

[0053] Sodium nitrite 1g / L

[0054] Potassium permanganate 2g / L

[0055] Tartaric acid 3g / L

[0056] water balance

[0057] The above-mentioned medium and low carbon steel wire rod drawing phosphating solution is obtained through the following steps:

[0058] (1) Add zinc dihydrogen phosphate and zinc nitrate to water accounting for 80% of the usage, and stir evenly;

[0059] (2) Add sodium chlorate, sodium nitrite, potassium permanganate, and tartaric acid to the mixture obtained in step (1), stir evenly, add the remaining water to constant volume to obtain the drawn medium and low carbon steel wire rod Phosphating solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com