Centrifugal casting machine of casting iron pan and centrifugal casting method thereof

A technology of centrifugal casting machine and cast iron pot, which is applied in the direction of casting mold, casting mold composition, casting molding equipment, etc. It can solve the problems that the surface cannot meet the production accuracy, the casting is not easy to be in place, and the productivity is hindered, so as to reduce the consumption of raw material metal and product quality. Production cost, improvement of surface quality, effect of reducing porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

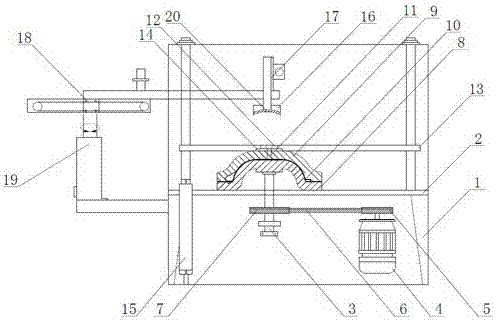

[0028] Embodiment 1: as figure 1 As shown, a cast iron pot centrifugal casting machine includes a frame 1, a lower support plate 2 is horizontally arranged on the frame 1, a rotating shaft 3 is vertically arranged on the lower support plate 2, and a rotating shaft 3 is arranged on the lower free end of the rotating shaft 3. The power drive mechanism further comprises a drive motor 4, a driving pulley 5, a drive belt 6 and a driven pulley 7, the drive pulley 5 is arranged on the motor shaft of the drive motor 4, and the driven pulley The pulley 7 is connected with the driving pulley 5 through the transmission belt 6 , and the driven pulley 7 is arranged on the lower free end of the rotating shaft 3 .

[0029] A lower mold 8 is arranged on the upper free end of the rotating shaft 3, and an upper mold 9 is arranged on the upper clutch of the lower mold 8, and a centrifugal chamber 10 is formed by fastening between the upper mold 9 and the lower mold 8, and the surface of the cent...

Embodiment 2

[0030] Embodiment 2: This casting machine also includes a manipulator discharge mechanism, and the manipulator discharge mechanism further includes an electromagnetic chuck 16, a lifting stroke cylinder 17, a translation stroke cylinder 18 and a rotating motor 19, and the electromagnetic chuck 16 is freely arranged on the lower mold 8 and outside the frame 1, the electromagnetic chuck 16 is installed on the lifting stroke cylinder 17, and the lifting stroke cylinder 17 is installed on the translation stroke cylinder 18, and the translation stroke cylinder 18 is installed on the rotary motor 19.

[0031] The lower end surface of the electromagnetic chuck 16 is a concave arc surface matched with the bottom of the pot, and several outwardly protruding heat-insulation flanges 20 are arranged on the concave arc surface.

[0032] A centrifugal casting method of a cast iron pot centrifugal casting machine, comprising the following steps:

[0033] (1) First, coat a layer of high-tempe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com