Thermo-oxidative aging resistant glass fiber reinforced polypropylene material and preparation method thereof

A polypropylene material, anti-thermal oxygen technology, applied in the field of polymers, can solve problems such as degradation, and achieve the effect of preventing oxidation chain reaction, superior anti-thermal oxygen aging, and excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

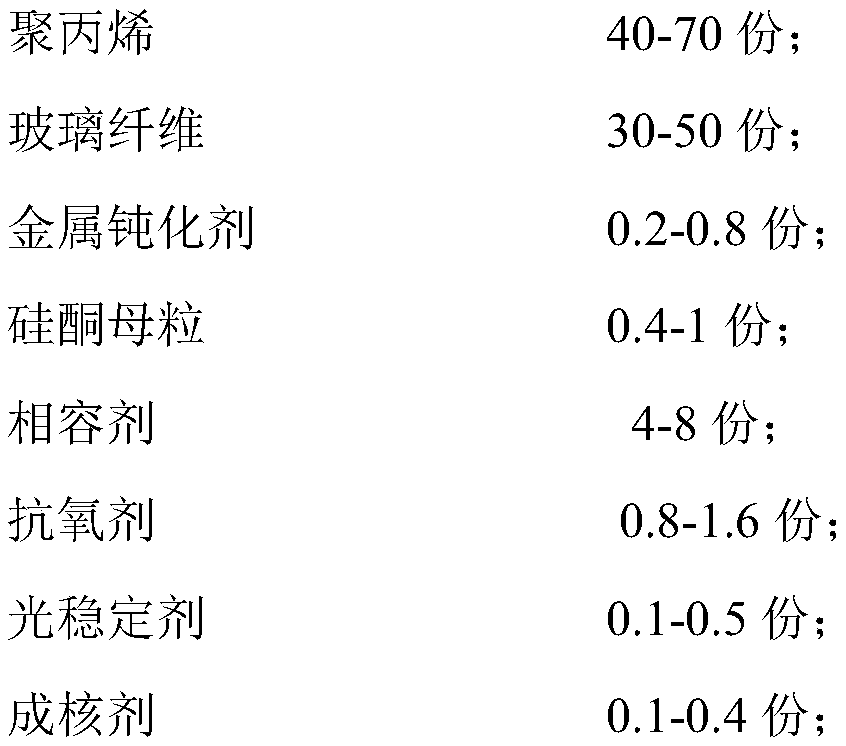

Method used

Image

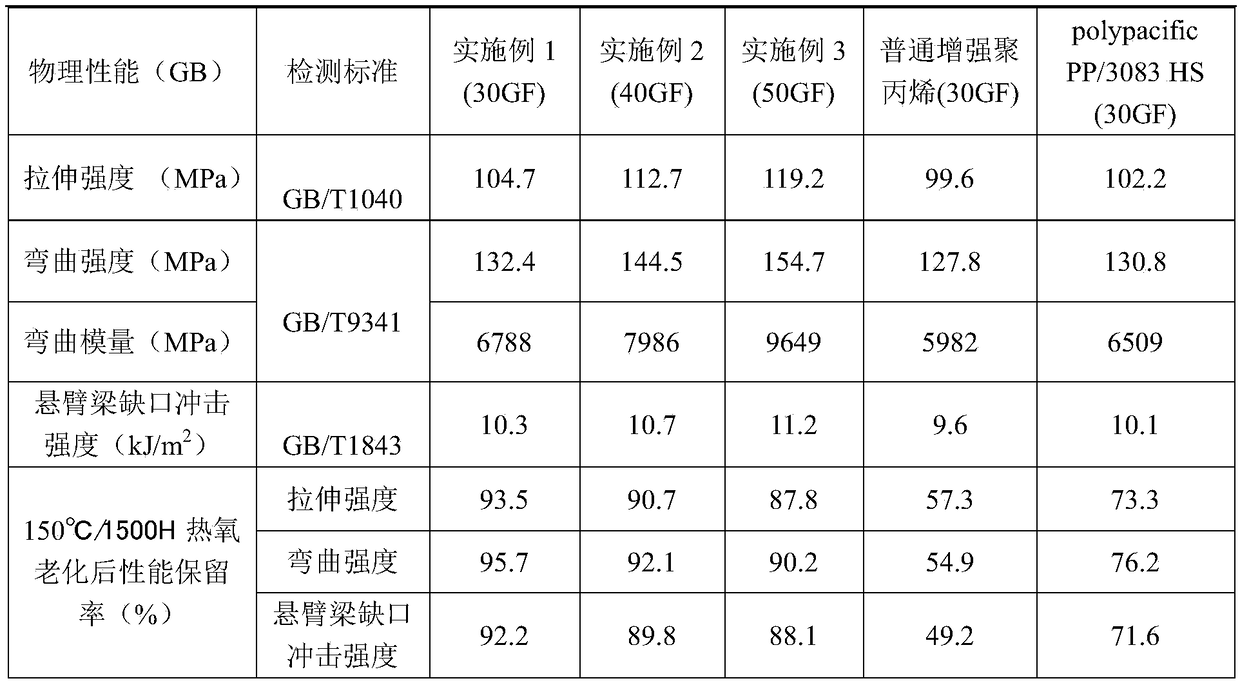

Examples

Embodiment 1

[0031] The preparation method of the anti-thermal and oxidative aging glass fiber reinforced polypropylene material in this embodiment comprises the following steps: take 64 parts of syndiotactic polypropylene according to the weight ratio, and the polypropylene grafted maleic anhydride 4 with a grafting rate of 1.5% 0.1 part of hindered amine light stabilizer, 0.4 part of DSTP, 0.15 part of α nucleating agent, 0.4 part of hindered phenol antioxidant, 0.3 part of polyethylene wax, 0.4 part of silicone masterbatch and 0.5 part of hydrazone compound, Add together in a mixer with nitrogen protection and mix at high speed for 2 minutes to obtain a mixed material; under nitrogen protection, put the mixed material into a twin-screw extruder to melt, and then add a diameter of 10 μm from the side feeding port of the extruder. 30 parts of glass fiber chopped strands with a length of 3.0 mm are extruded and granulated to obtain a thermal and oxidative aging-resistant glass fiber reinfor...

Embodiment 2

[0033] The preparation method of the anti-thermal and oxidative aging glass fiber reinforced polypropylene material in this embodiment comprises the following steps: take 40 parts of random polypropylene and 5 parts of polypropylene grafted maleic anhydride with a grafting rate of 1.7% by weight , 0.3 part of hindered amine light stabilizer, 0.6 part of DSTP, 0.2 part of α nucleating agent, 0.4 part of phosphite antioxidant, 0.2 part of ethylene bis stearamide, 0.6 part of silicone masterbatch and N, N 0.2 parts of '-disubstituted hydrazine compound, add together in a mixer with nitrogen protection and mix at high speed for 6 minutes to obtain a mixed material; under nitrogen protection, put the mixed material into a twin-screw extruder to melt, and then Add 40 parts of glass fiber chopped strands with a diameter of 12 μm and a length of 4.0 mm to the side feeding port of the side feed port, and extrude and granulate to obtain a thermal-oxidative aging-resistant glass fiber-rei...

Embodiment 3

[0035]The preparation method of the anti-thermal and oxidative aging glass fiber reinforced polypropylene material in this embodiment comprises the following steps: Weigh 70 parts of syndiotactic polypropylene and atactic polypropylene according to the weight ratio, and the polypropylene grafting ratio is 2.0%. 8 parts branched maleic anhydride, 0.5 parts hindered amine light stabilizer, 0.7 parts DSTP, 0.4 parts α nucleating agent, 0.9 parts phosphite antioxidant, 0.3 parts stearate, grafted ethylene dihard Add 0.2 part of fatty amide, 1 part of silicone masterbatch, 0.3 part of aromatic hydrazide compound and 0.5 part of hydrazone compound into a mixer with nitrogen protection and mix at high speed for 10 minutes to obtain a mixed material; under nitrogen protection, the mixture Put the material into a twin-screw extruder to melt, and then add 50 parts of glass fiber chopped strands with a diameter of 14 μm and a length of 4.5 mm from the side feeding port of the extruder, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com