Manufacturing process and equipment for storage battery hauling net lead strip or net punching plate gate lead strip

A technology of manufacturing equipment and manufacturing process, which is applied in the field of manufacturing process and equipment of stretched or punched grid lead belt, and the production process and equipment of battery grid lead belt, which can solve the problem of affecting the composition and performance of lead alloy and endangering the health of workers. Health, lead smoke environmental pollution and other issues, to achieve the effect of reducing lead smoke pollution, reducing energy consumption and material loss, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

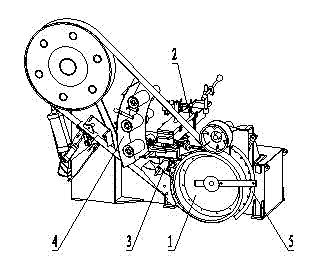

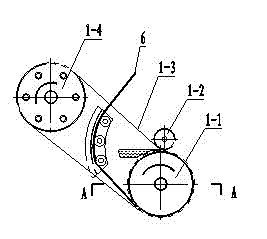

Image

Examples

Embodiment Construction

[0030] The manufacturing process provided by the present invention is to melt the electrolytic lead and add alloy elements, then transport it to the lead belt continuous casting machine and cast it into a rough alloy lead belt, and then use the rough alloy lead belt as raw material to continuously roll the lead belt The machine is directly cold-rolled into a refined lead strip that can be used for stretching or flushing. The specific operation steps are as follows:

[0031] a. Melting the electrolytic lead, melting the electrolytic lead, adding alloy elements and stirring evenly, the proportion of alloy elements in the lead liquid is: calcium element content 0.05-0.09%, aluminum element content 0.02-0.04%, bismuth element content ≤ 0.003%.

[0032] b. Lead liquid delivery, which transports the melted and added alloy elements to the lead liquid supply system of the continuous casting machine. During this process, the lead liquid is controlled by the liquid level control device a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com