Double-pulse cyanide-free alkali silver electroplating method

A dual-pulse, electroplating silver technology, applied in the field of pulse electroplating technology and cyanide-free electroplating silver technology, can solve the problems of endangering the health of operators, high toxicity of cyanide plating solution, and incomplete replacement, and achieves a wide range of process parameters, Strong throwing and covering power, easy handling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

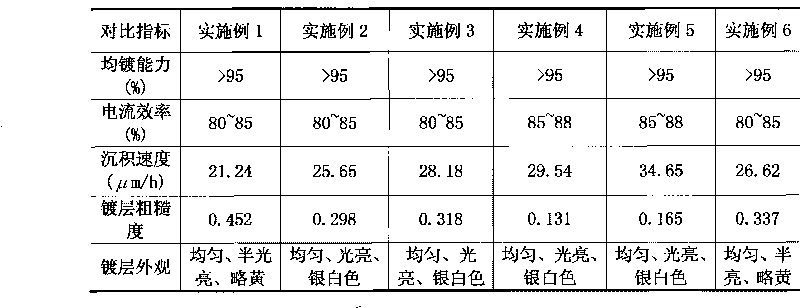

Examples

Embodiment 1

[0017] The formula of double-pulse cyanide-free alkaline electroplating silver is:

[0018] Silver nitrate 35g / L; sodium thiosulfate 180g / L; ammonium thiosulfate 50g / L; sodium metabisulfite 45g / L; sodium sulfate 10g / L; boric acid 25g / L; gelatin: 0.3g / L.

[0019] The process conditions of double-pulse cyanide-free alkaline electroplating silver are: the duty cycle of forward and reverse pulses is 10% and 10% respectively, and the average current density of forward and reverse pulses is 1.0A / dm respectively 2 and 0.1A / dm 2 . The forward and reverse pulse working time is 100ms and 10ms respectively. The pH value of the electroplating solution is between 4.0 and 4.5, the temperature of the plating solution is 25° C., and the mechanical stirring speed is 100 rpm to 150 rpm.

Embodiment 2

[0021] The formula and process conditions of double-pulse cyanide-free alkaline electroplating silver are basically the same as in Example 1, except that the average current density of forward and reverse pulses is 2.0A / dm respectively 2 and 0.2A / dm 2 .

Embodiment 3

[0023] The formula and process conditions of the double-pulse cyanide-free alkaline electroplating silver are basically the same as in Example 1, except that the average current density of the forward and reverse pulses is 3.0A / dm respectively 2 and 0.3A / dm 2 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com