Non-nickle ion phosphating agent for steel plate processing

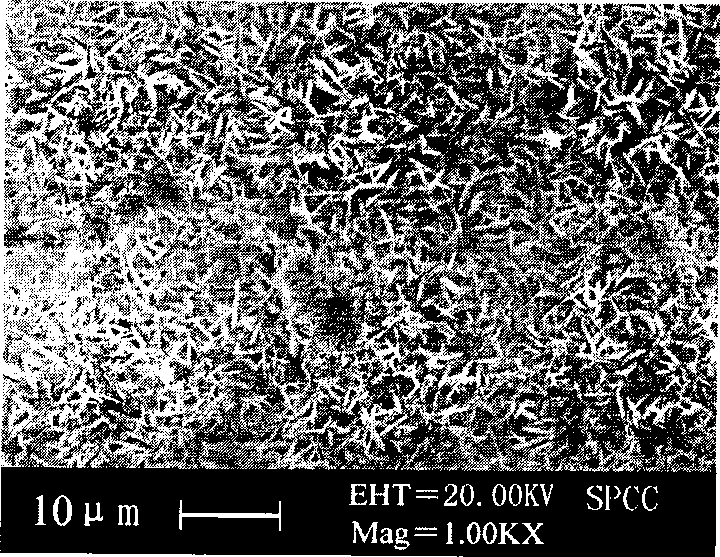

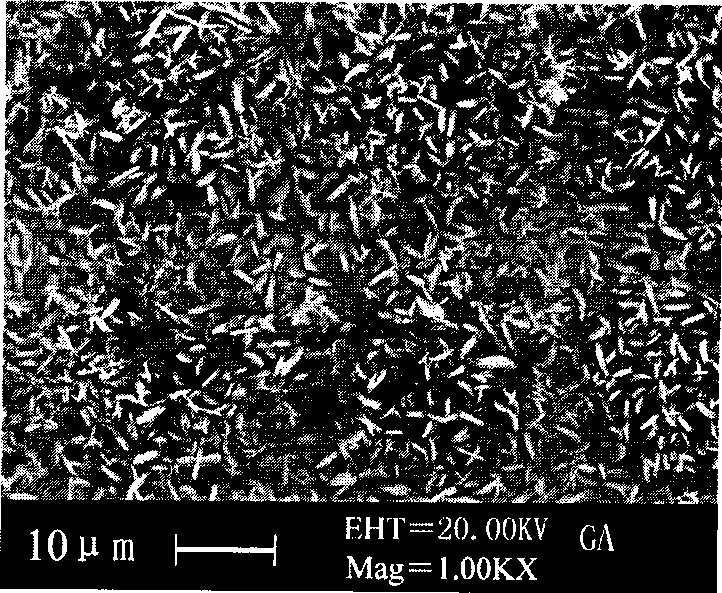

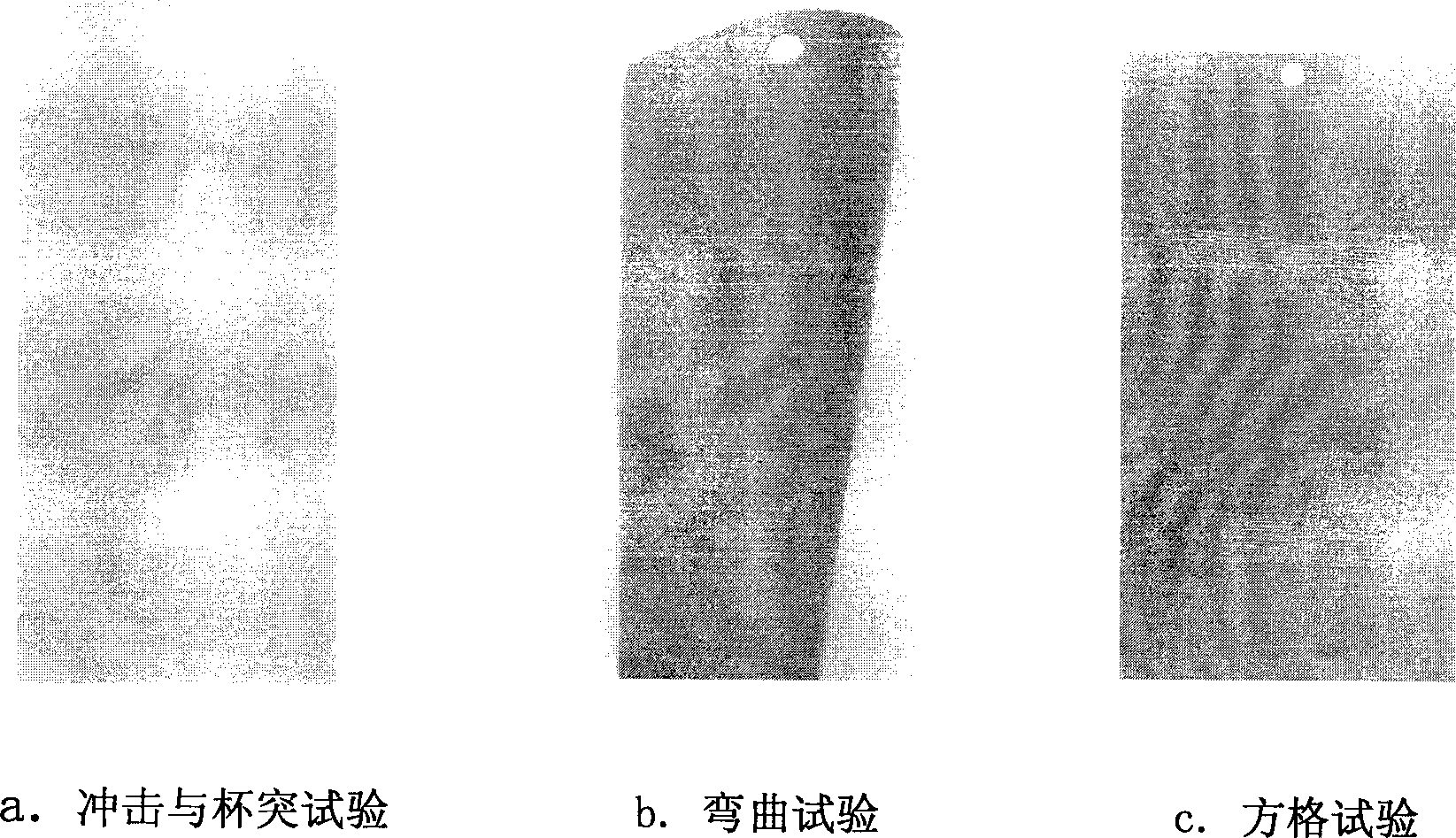

A nickel ion and phosphating agent technology, applied in the direction of metal material coating process, can solve the problems of high cost, environmental protection restrictions, damage, etc., and achieve the effects of low product cost, dense crystallization and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Product of the present invention is made up of following material by weight percentage:

[0024] Phosphoric acid 35%

[0031] water balance

[0032] The preparation method of the phosphating agent of the present invention is: in a container of known volume, firstly add water and phosphoric acid, then add zinc oxide under stirring, after the zinc oxide is fully dissolved, add manganese carbonate and sodium carbonate in turn, and finally add Magnesium nitrate, cobalt nitrate, sodium tungstate, stir well and serve.

Embodiment 2

[0034] Product of the present invention is made up of following material by weight percentage:

[0035] Phosphoric acid 40%

[0037] Manganese Carbonate 3.5%

[0039] Cobalt nitrate 1%

[0041] Sodium Carbonate 7%

[0042] water balance

[0043] The preparation method is the same as in Example 1.

Embodiment 3

[0045] Product of the present invention is made up of following material by weight percentage:

[0046] Phosphoric acid 45%

[0048] Manganese Carbonate 4%

[0049] Magnesium Nitrate 8%

[0050] Cobalt nitrate 1.1%

[0051] Sodium Tungstate 0.2%

[0052] Sodium Carbonate 8%

[0053] water balance

[0054] The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com