Direct spraying type automatic bean bar production equipment

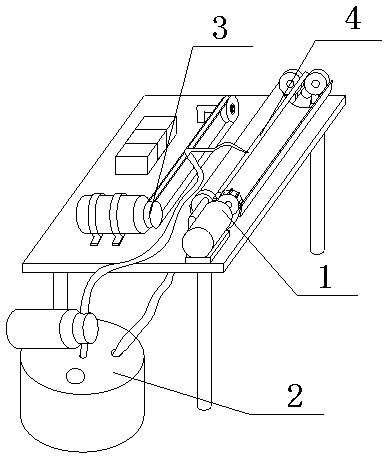

A kind of production equipment, direct-injection technology, applied in the field of direct-injection automatic bean stick production equipment, can solve the problems of affecting the quality of bean stick rolling, uneven pulling of bean skin, low rolling efficiency, etc., so as to facilitate fixed connection , Novel structure, convenient recycling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

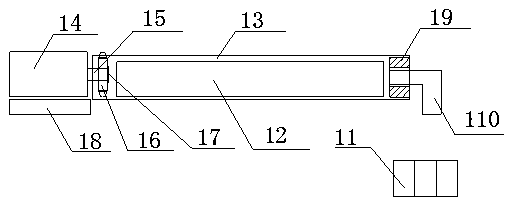

[0027] Specific implementation method: when in use, the operator turns on the power switch to heat the electric heating plate 12. After the electric heating plate 12 reaches a certain temperature, the round rod 4 is placed between the spur gear 16 and the bearing, and the No. 1 motor 14 switch is turned on. No. motor 14 drives spur gear 16 to rotate, and spur gear 16 drives round bar 4 to rotate.

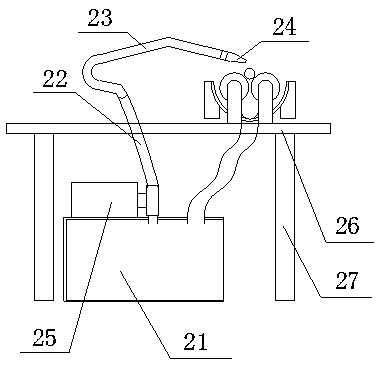

[0028] Open water suction machine 25 switches, soya-bean milk is sucked into water nozzle 24, and water nozzle 24 sprays soya-bean milk, and soya-bean milk flows on the round rod 4, flows into half cylinder 13 again, flows into water tank 21 by water pipe 22 at last.

[0029] Open No. two motor 31 switch, No. two motor 31 drives chain 34 to rotate, because flexible pipe 23 is fixed on the chain 34, so flexible pipe 23 is driven by chain 34, moves left and right, thereby realizes the purpose of spraying round bar 4 evenly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com