PVDF metal powder coating for metal surface, and preparation method thereof

A metal powder and metal surface technology, applied in the field of PVDF metal powder coating and its preparation, can solve problems such as no specific solutions are proposed, and achieve the effect of improving the probability of entanglement, good weather resistance, and not easy to agglomerate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

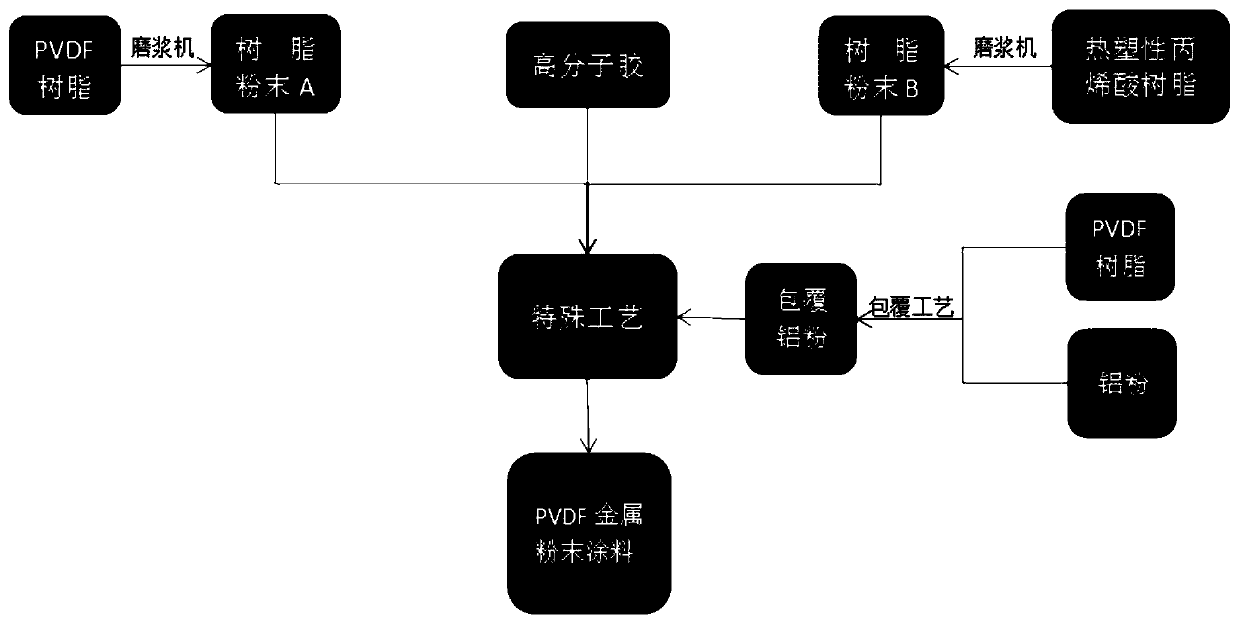

Method used

Image

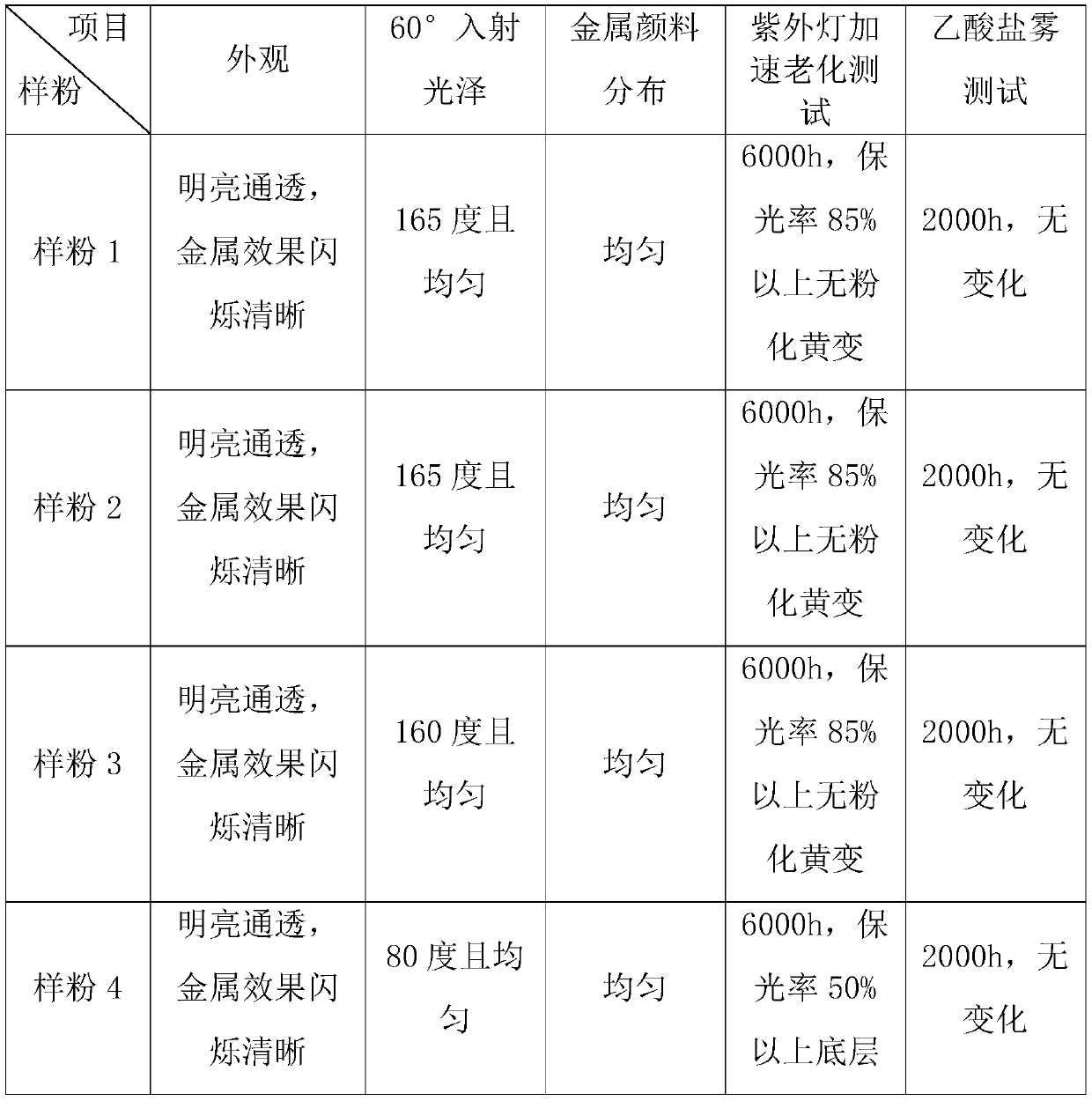

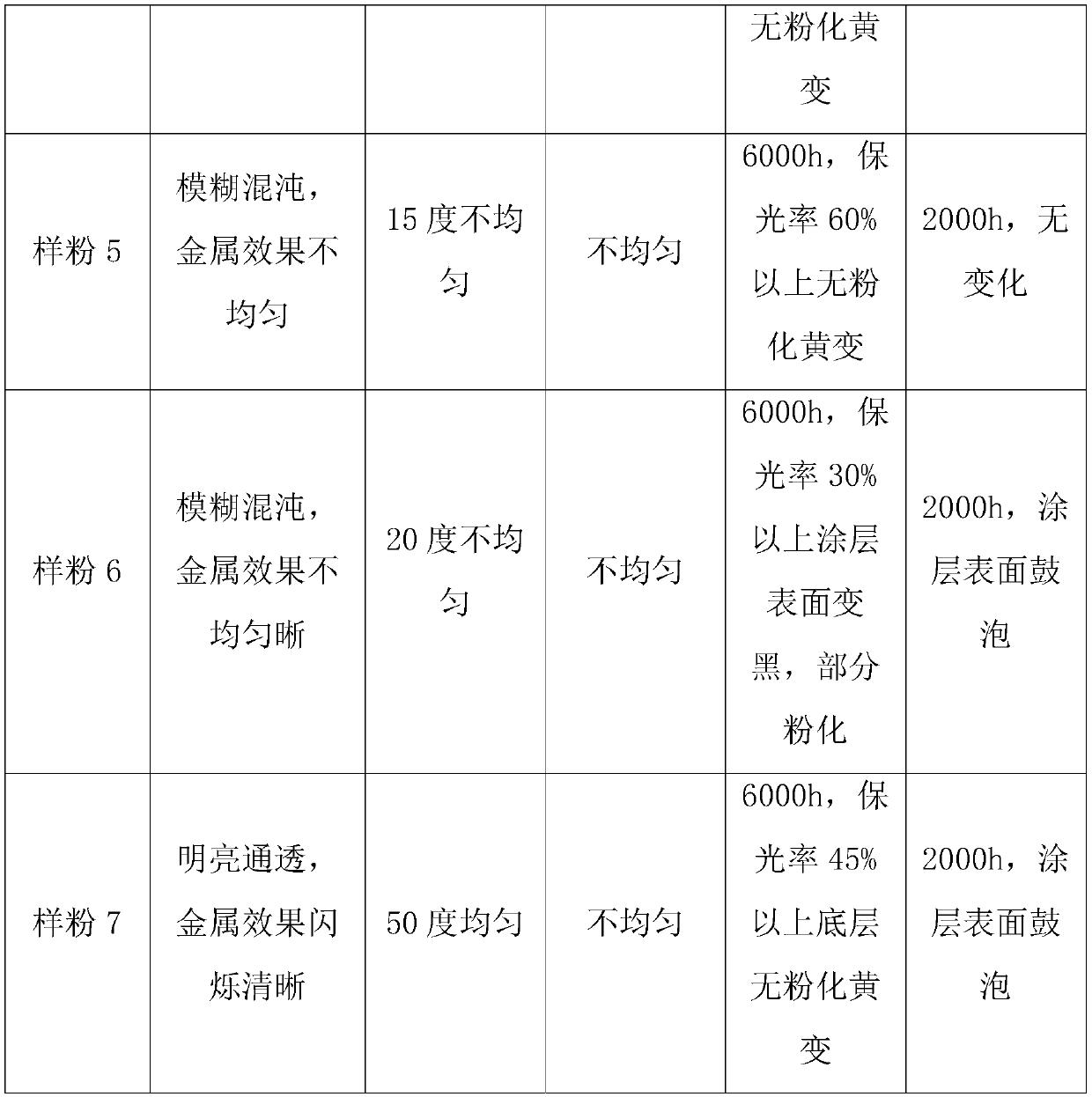

Examples

Embodiment 1

[0041] A PVDF metal powder coating for metal surfaces. The PVDF metal powder coating for metal surfaces is mixed with resin powder A and resin powder B in a weight percentage of 7:3, and then by adding polymer glue and coating aluminum powder Prepared

[0042] The added amount of the polymer glue is 10.0% of the total resin weight percentage;

[0043] The added amount of the coated aluminum powder is 20.0% by weight of the total resin.

[0044] Wherein, the resin powder A is composed of PVDF resin; the resin powder B is composed of thermoplastic acrylic resin; the PVDF resin is a homopolymer or copolymer of vinylidene fluoride monomer; and the thermoplastic acrylic resin is MMA / EA copolymer; the polymer glue is a copolymer of methacrylate and vinyl monomer; the coated aluminum powder is a mixture of PVDF resin and aluminum powder.

[0045] In the present invention, the resin powder A and the resin powder B are ground by a refiner, and the refiner is provided with a grinding cavity a...

Embodiment 2

[0056] A PVDF metal powder coating for metal surface. The PVDF metal powder coating for metal surface is mixed with resin powder A and resin powder B in a weight percentage of 3:7, and then by adding polymer glue and coating aluminum powder Prepared

[0057] The added amount of the polymer glue is 5.0% of the total resin weight percentage;

[0058] The added amount of the coated aluminum powder is 20.0% by weight of the total resin.

[0059] Wherein, the resin powder A is composed of PVDF resin; the resin powder B is composed of thermoplastic acrylic resin; the PVDF resin is a homopolymer or copolymer of vinylidene fluoride monomer; and the thermoplastic acrylic resin is MMA / EA copolymer; the polymer glue is a copolymer of methacrylate and vinyl monomer; the coated aluminum powder is a mixture of PVDF resin and aluminum powder.

[0060] In the present invention, the resin powder A and the resin powder B are ground by a refiner, and the refiner is provided with a grinding cavity and ...

Embodiment 3

[0071] A PVDF metal powder coating for metal surfaces. The PVDF metal powder coating for metal surfaces is mixed with resin powder A and resin powder B in a weight percentage of 7:3, and then by adding polymer glue and coating aluminum powder Prepared

[0072] The added amount of the polymer glue is 8.0% of the total resin weight percentage;

[0073] The added amount of the coated aluminum powder is 20.0% by weight of the total resin.

[0074] Wherein, the resin powder A is composed of PVDF resin; the resin powder B is composed of thermoplastic acrylic resin; the PVDF resin is a homopolymer or copolymer of vinylidene fluoride monomer; and the thermoplastic acrylic resin is MMA / EA copolymer; the polymer glue is a copolymer of methacrylate and vinyl monomer; the coated aluminum powder is a mixture of PVDF resin and aluminum powder.

[0075] In the present invention, the resin powder A and the resin powder B are ground by a refiner, and the refiner is provided with a grinding cavity an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com