High-voltage electrostatic oiling system

A high-voltage electrostatic and high-voltage electrostatic generation technology, applied in liquid spraying equipment, spraying devices, etc., can solve problems such as uneven paint spraying, large paint loss, and uneven paint coating.

Active Publication Date: 2013-02-20

大庆北油工程技术服务有限公司

View PDF2 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a high-voltage electrostatic oiling system to solve the problems of uneven paint coating and large paint loss on the outer surface of existing steel strips, steel pipes, and steel wires.

The present invention uses one paint spraying device to replace multiple paint spraying devices in the existing production line, and solves the problem of uneven paint spraying in overlapping areas caused by multiple paint spraying devices working at the same time; the present invention utilizes the principle of electrostatic adsorption , the negative high voltage is connected to the rotary cup, and the oil, paint or anti-corrosion material is sprayed and charged; through the adsorption of the sprayed paint by the workpiece after charging, the paint is evenly coated on the outer surface of the workpiece The purpose of the invention; the present invention reclaims the residual paint in the paint spraying process by the recovery device of the paint, and recycles it, so that the utilization rate of the paint is increased to 95% from 65% of the prior art

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

specific Embodiment approach 1

specific Embodiment approach 2

specific Embodiment approach 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

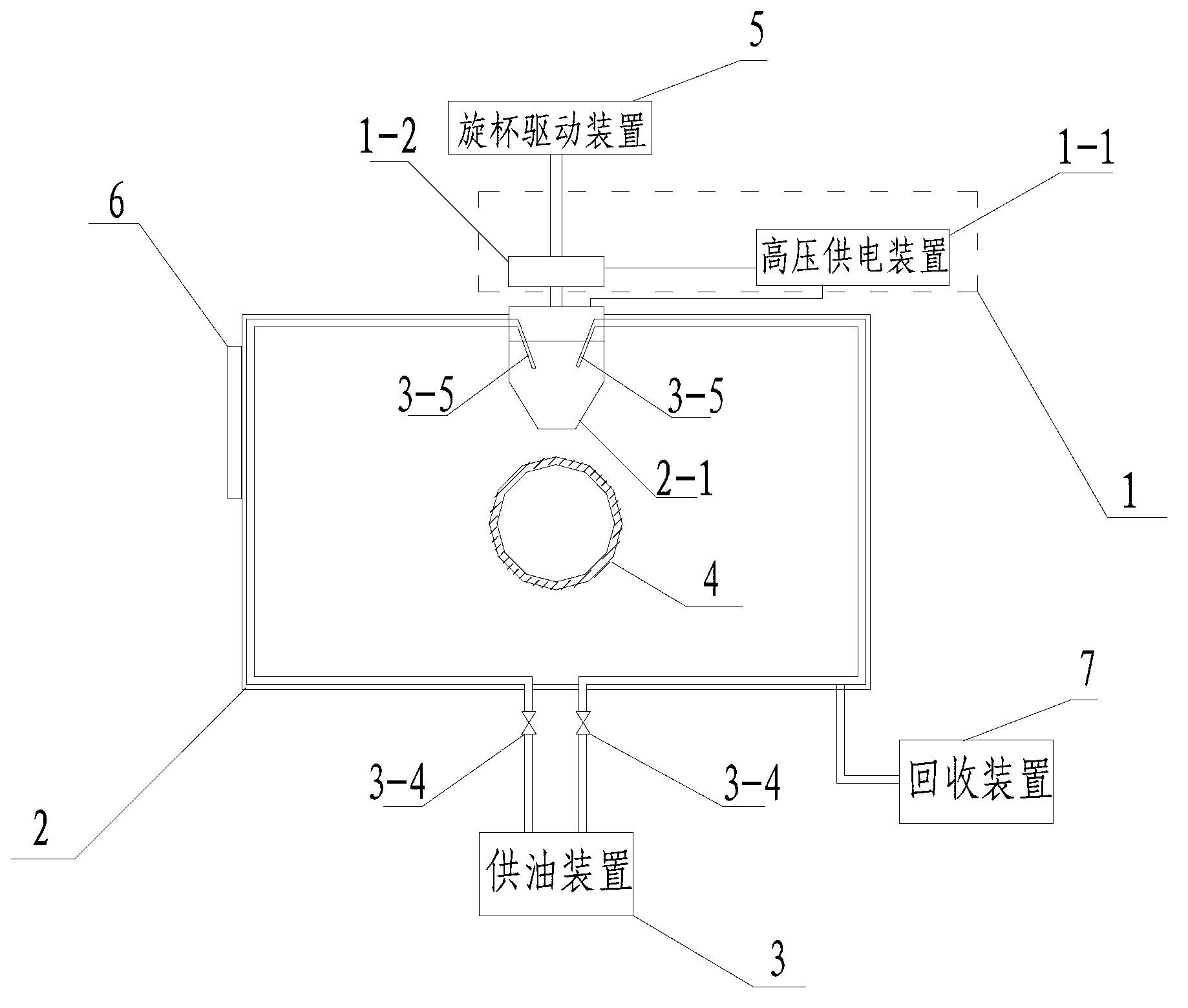

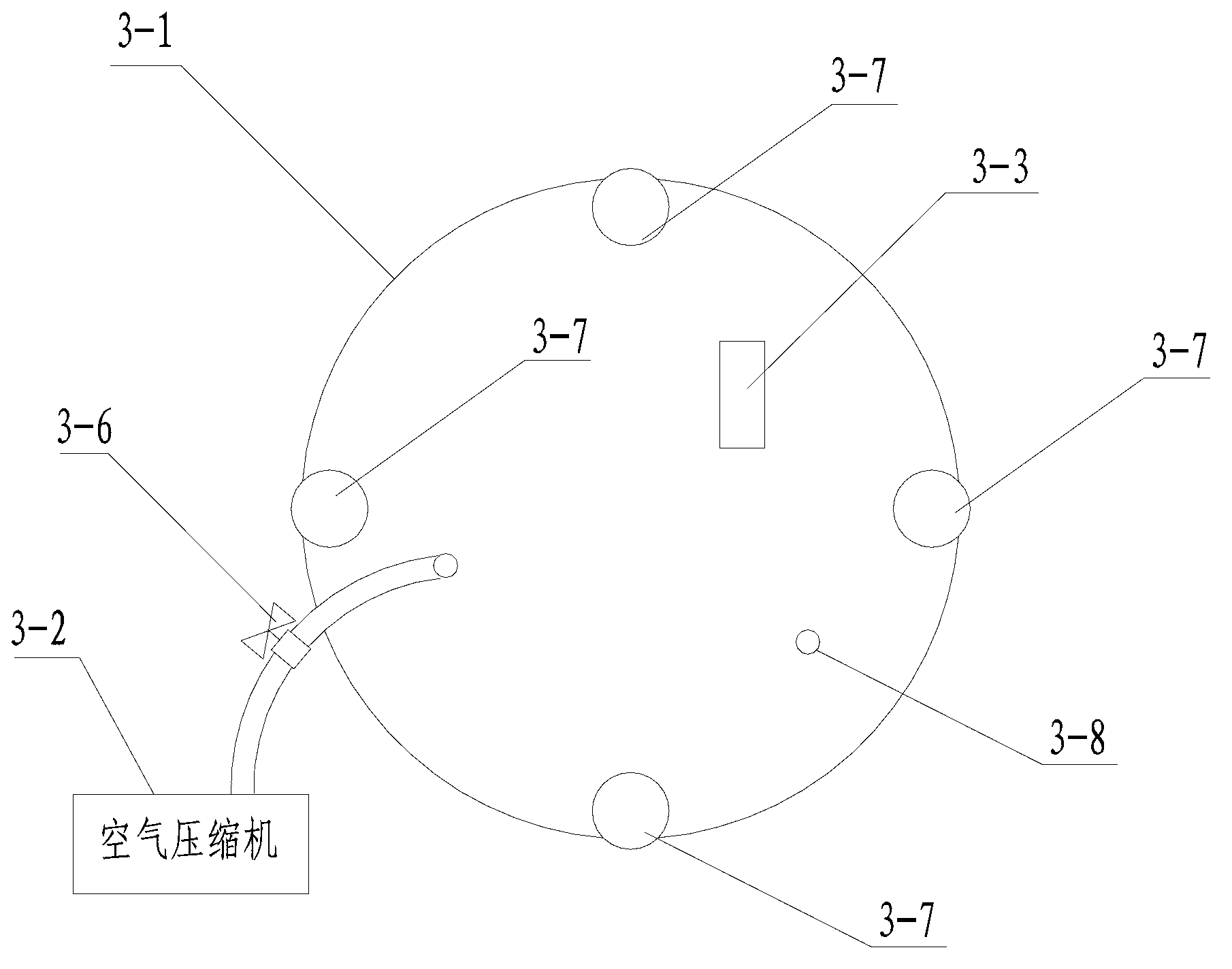

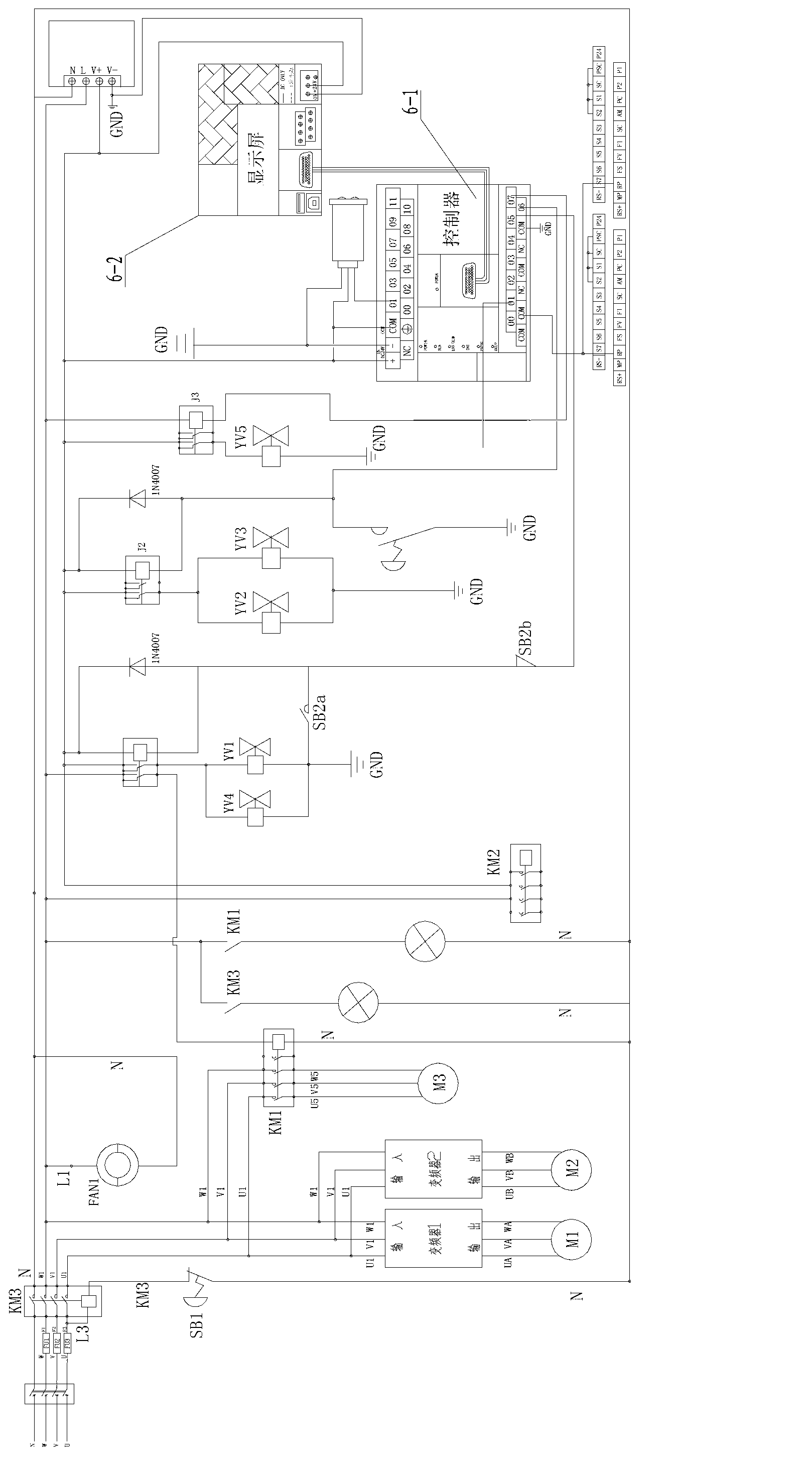

A high-voltage electrostatic oiling system relates to spray coating devices used on production lines, and aims to solve the problems in the prior art that outer surfaces of steel belts, steel tubes and steel wires are not coated with paint uniformly, and the paint loss is large. The high-voltage electrostatic oiling system includes a high-voltage electrostatic generation device, an oiling box, an oil supply device, a workpiece conveying device, a rotary cup driving device, a control unit and a recovery device; the oiling box is provided with a box body, a through hole is formed at the center of the top of the box body, the rotary cup driving device is arranged above the through hole, a rotary cup is arranged in the through hole, a driving output end of the rotary cup driving device is communicated with a driving input end of the rotary cup, and a cup mouth of the rotary cup faces downward to an inner cavity of the oiling box; the oiling device comprises an oil barrel, an air compressor, a pressure gauge, an electromagnetic valve, two oil output valves and two oil nozzles; the control unit includes a controller and a display screen; and an input port of the recovery device is communicated with the inner cavity of the oiling box. The high-voltage electrostatic oiling system is suitable for oiling various production lines continuously.

Description

Technical field [0001] The invention involves the production line spraying device. Background technique [0002] At present, the coating (oil, paint, anticorrosive material) on the surface of the surface of steel bands, steel pipes, steel wire wires, and other production lines are used. Multiple coating spraying devices work at the same time.The problem of unevenness and large paint loss, and uneven coating coating directly affects the service life of steel wire. Invention content The purpose of the present invention is to solve the problem of existing steel belts, steel pipes, and wire wires on the surface of the outer surface of the wire. The paint on the surface of the surface of the wire is unevenly coated and the coating loss is large. A high -voltage electrostatic oil coating system, which includes high -voltage electrostatic incident devices, fuel tanks, fuel supply devices, workpiece conveying devices, rotary cup drivers, control units and recycling devices., The power...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B05B5/08B05B5/10B05B15/04

CPCY02P70/36Y02P70/10

Inventor 朴恩哲田治国

Owner 大庆北油工程技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com