Gantry type orchard spraying mechanism

A spraying mechanism, gantry-type technology, applied in the field of gantry-type orchard spraying mechanism, can solve problems such as uneven spraying operations in terraced fields

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

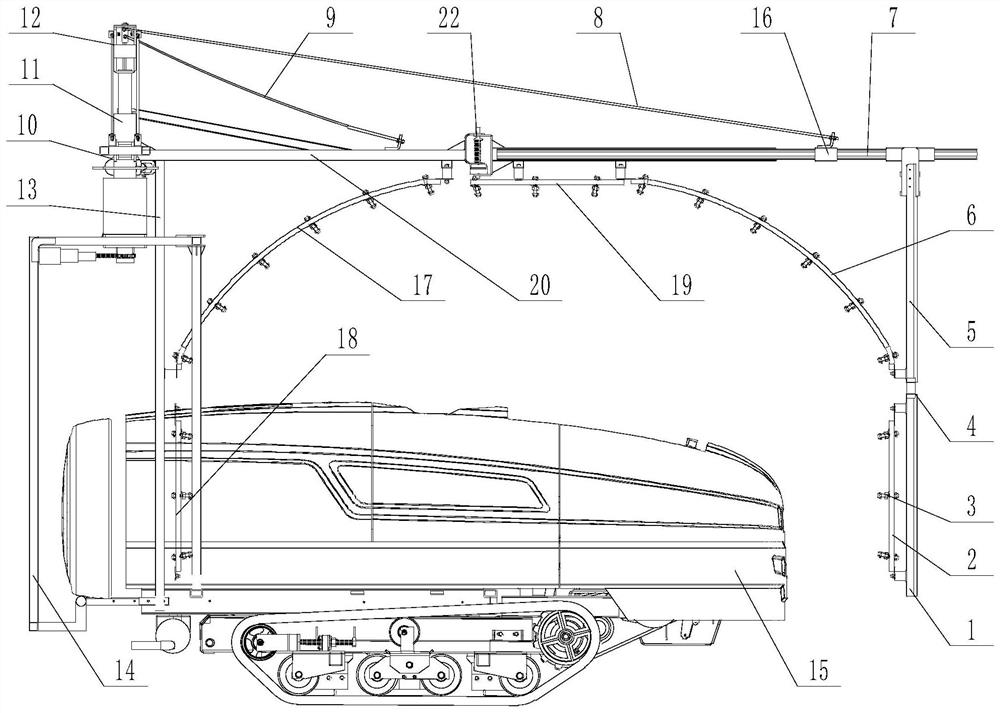

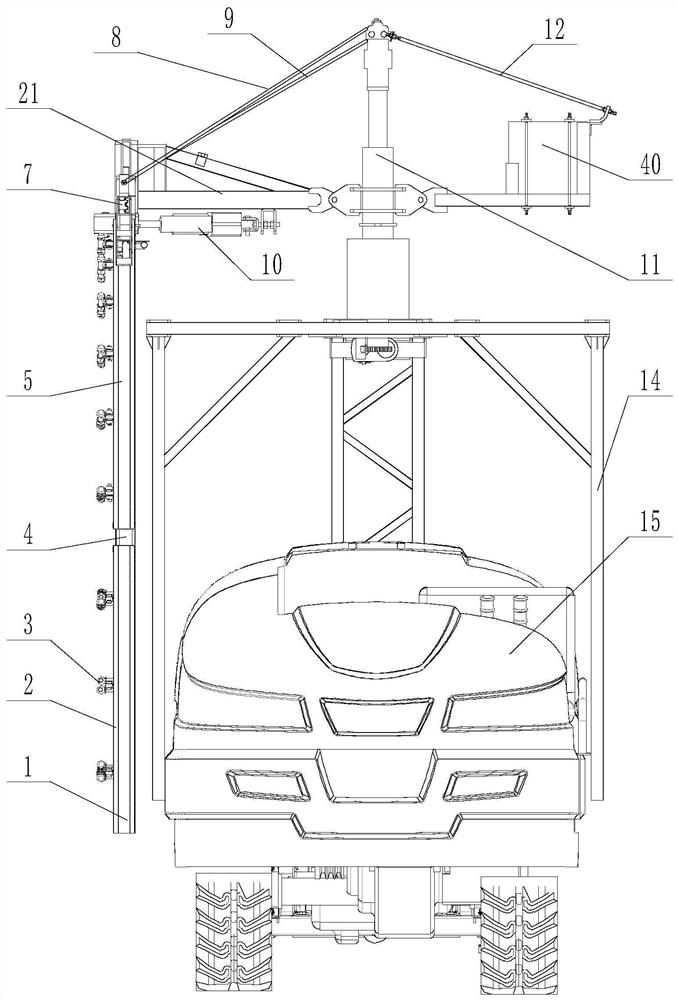

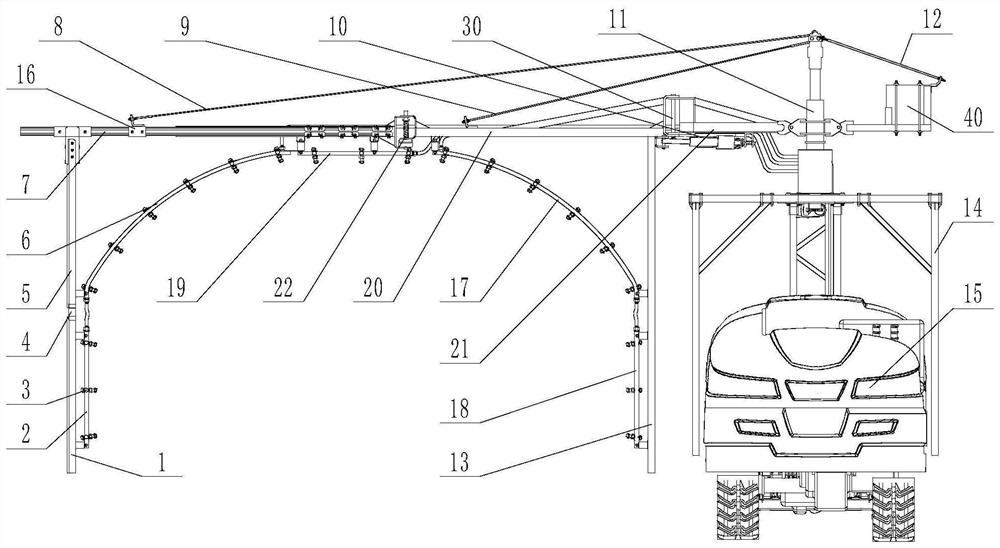

[0026] Such as figure 1 As shown, a gantry-type orchard spraying mechanism includes a frame 14, the frame 14 is provided with a rotating mechanism, the rotating mechanism is provided with a leveling mechanism and a boom fixing arm 21, and the boom fixing arm 21 passes through the spray boom The connecting arm 20 and the spray rod anti-collision mechanism 22 are connected with the spray rod 7, and the lower ends of the spray rod connecting arm 20 and the spray rod 7 are provided with a spray rod support mechanism.

Embodiment 2

[0028] A gantry type orchard spraying mechanism, the rotating mechanism includes a rotating shaft 11, an electric push rod B31, a rack 32, an upper fixing plate 34, a lower fixing plate 35 and a support tube 36, and the support tube 36 is installed on the frame 14 , and the support tube 36 is installed between the upper fixed plate 34 and the lower fixed plate 35, the upper fixed plate 34 and the lower fixed plate 35 are connected by bolts, the upper fixed plate 34 is provided with a rotating shaft fixing tube 33, and the rotating shaft 11 is connected from the upper Pass through the rotating shaft fixing pipe 33, the upper fixing plate 34, the support pipe 36 and the lower fixing plate 35 successively, the lower end of the rotating shaft 11 is equipped with a gear 39, and one end of the electric push rod B31 is installed and fixed on the frame 14. One end is connected with the rack 32, and the rack 32 is meshed with the gear 39 for transmission connection.

[0029] The spray ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com