Sea water spraying system of sea water desalting device

A spray system and seawater technology, applied in the field of spray systems, can solve the problems affecting the output and operation stability of equipment, blockage of spray system pipelines, small spray particle size of solid cone nozzles, etc., to achieve good spray The effect of uniformity, safe operation prevention, and stable nozzle structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

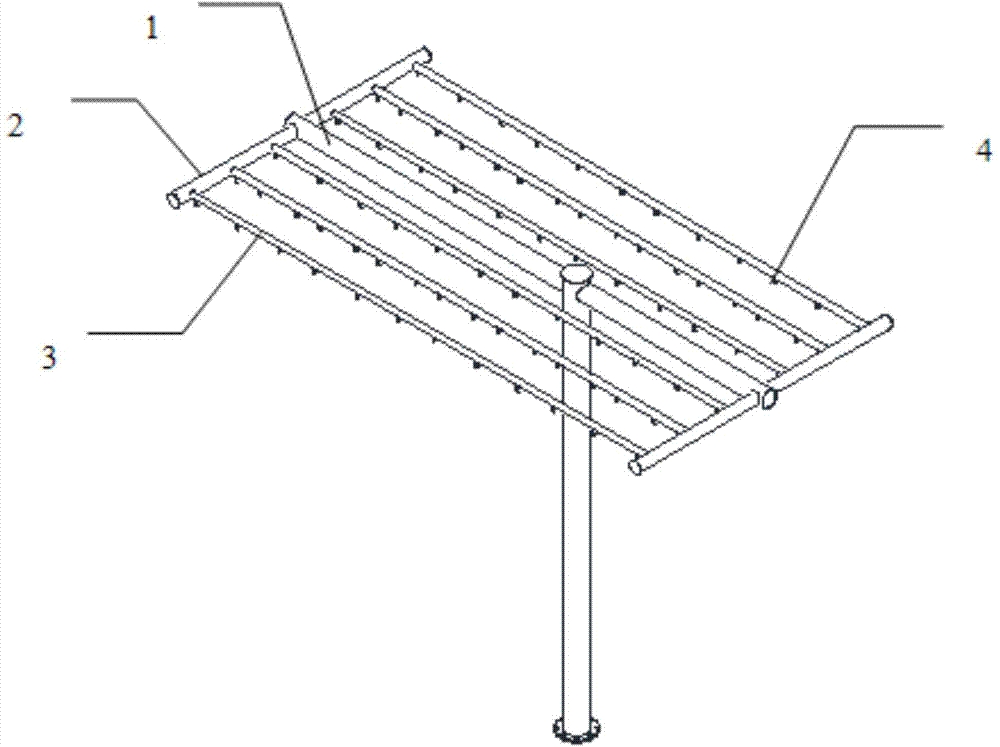

[0023] The seawater spray system of the present invention is arranged in the evaporator device of the seawater desalination system, and includes a support frame 1, a spray pipeline, and more than one nozzle. The spray pipe includes a spray main pipe 2 and a spray branch pipe 3, and the nozzle The socket is evenly arranged on the spray branch pipe 3, and the nozzle 4 is connected to the nozzle socket. They are respectively threaded and fixed with thread sealant.

[0024] The improvement of the present invention for the original spraying system lies in:

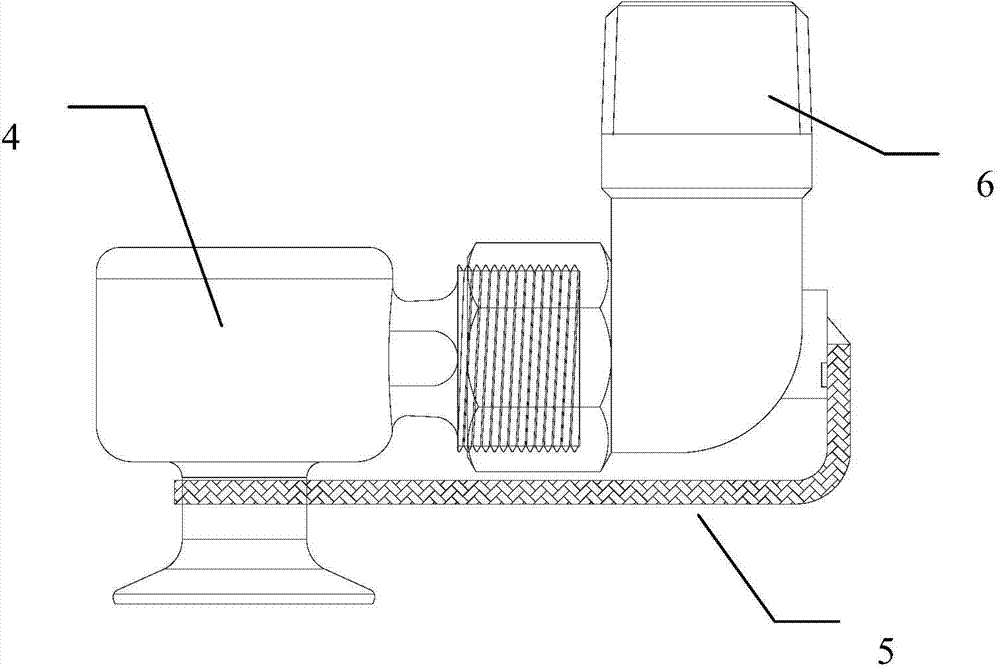

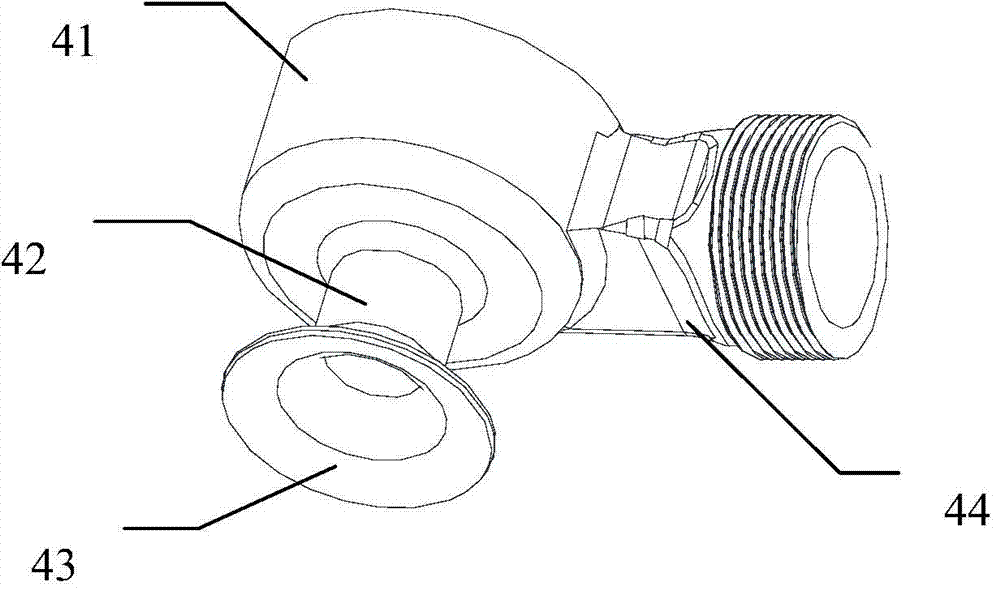

[0025] 1) if figure 2 , 3 As shown, without changing the spray pipes of the existing spray system and the arrangement of spray nozzles, the original solid cone nozzles are directly replaced with new tangential centrifugal nozzles.

[0026] The nozzle includes a cylindrical swirl chamber 41 , a water inlet 44 arranged on the side of the swirl chamber, a nozzle throat 42 and a spout 43 arranged at the bottom of the swirl cham...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com