Method for repairing steel rail with laser

A technology of laser repair and rail, which is applied in the direction of track, track laying, track maintenance, etc., can solve the problems of difficult replacement, achieve the effect of simple repair equipment, simple repair method, and reduce post-processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

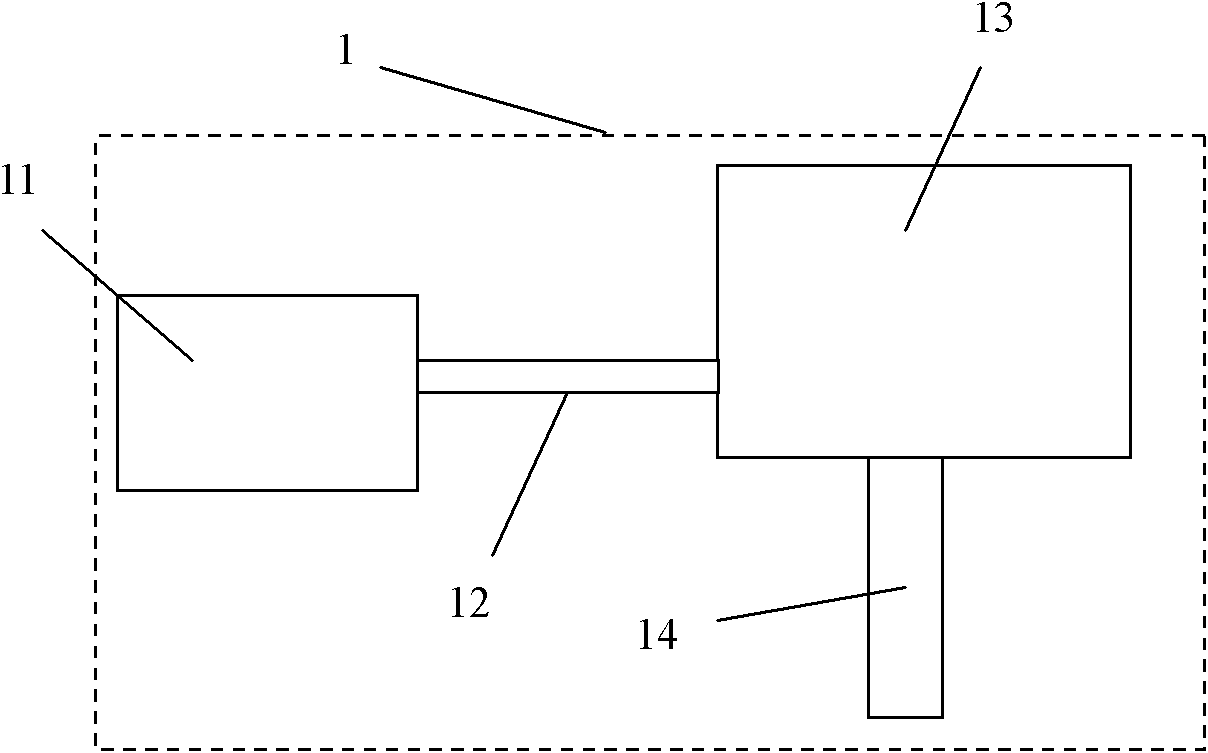

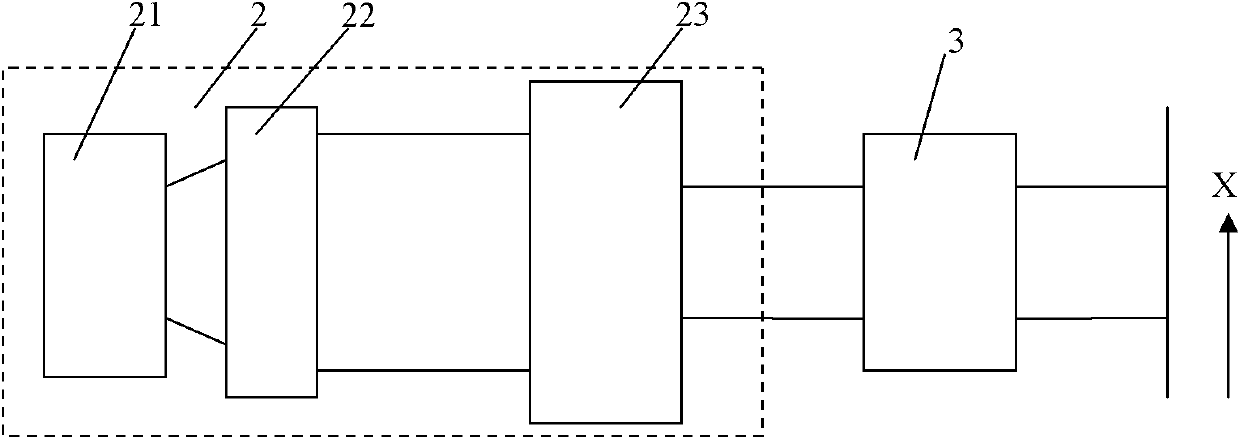

[0021] The present invention will be further described in detail below in conjunction with the drawings.

[0022] The method of the present invention for repairing steel rails by laser is completed by the following steps:

[0023] Step 1. Set the height direction of the rail as the Y axis, the width direction of the rail as the X axis, and the length direction of the rail as the Z axis;

[0024] Step 2: Scan the track with the CCD camera, and collect the values in the X and Y directions;

[0025] Step 3: Compare the Y-direction value collected by the CCD camera in Step 2 with the height of the standard rail surface in the computer. If the difference is ≥1mm, then the point (X, Y) is judged to be the damage to be repaired. Perform step 4, if the difference is less than 1mm, then it is determined that the point (X, Y) does not need to be repaired, and return to step 2;

[0026] Step 4. Record the height of the standard rail surface as Y=0, the height difference in the Y direction is th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| conversion efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com