Treatment method of garbage leachate

A technology of landfill leachate and a treatment method, applied in the field of landfill leachate treatment, can solve the problems of low biochemical degradation performance, difficult treatment, environmental and ecological pollution, etc., and achieve sludge reduction, resource utilization, and saving. The effect of investment and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

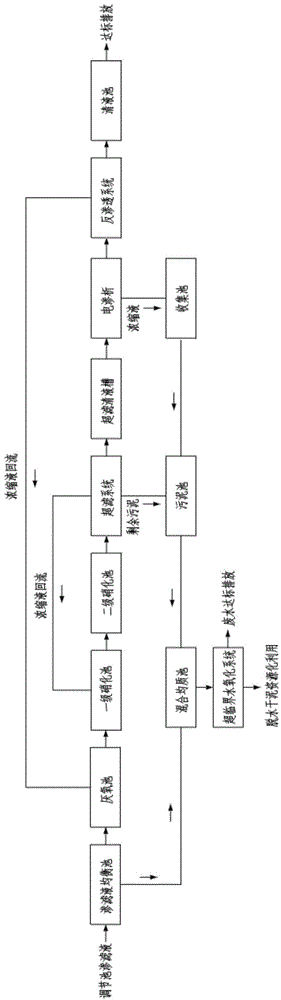

Image

Examples

Embodiment 1

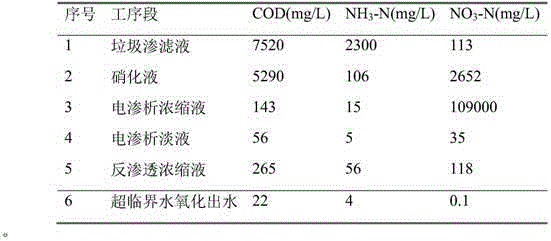

[0024] A method for treating landfill leachate, comprising introducing leachate from a landfill adjustment tank into a leachate balance tank; adjusting the pH value of the leachate to 6.5 in the leachate balance tank, and adjusting the pH value with lye, the lye being hydrogen oxidized Sodium solution or lime water.

[0025] Part of the effluent I of the leachate equalization tank degrades organic pollutants through the anaerobic tank, ammonifies organic nitrogen, and then enters the first-level nitrification tank and the second-level nitrification tank in turn to degrade organic pollutants and carry out ammonia nitrification, and then enters The ultrafiltration system, the ultrafiltration concentrated solution is returned to the first-stage nitrification tank, the ultrafiltered fresh water enters the ultrafiltration liquid tank, and then introduced into the electrodialysis system, after the inorganic salt is concentrated, the fresh water enters the reverse osmosis system, and ...

Embodiment 2

[0034] A method for treating landfill leachate, comprising introducing leachate from a landfill adjustment tank into a leachate balance tank; adjusting the pH value of the leachate to 7 in the leachate balance tank, and adjusting the pH value with lye, the lye being hydrogen oxidized Sodium solution or lime water.

[0035] Part of the effluent I of the leachate equalization tank degrades organic pollutants through the anaerobic tank, ammonifies organic nitrogen, and then enters the first-level nitrification tank and the second-level nitrification tank in turn to degrade organic pollutants and carry out ammonia nitrification, and then enters The ultrafiltration system, the ultrafiltration concentrated solution is returned to the first-stage nitrification tank, the ultrafiltered fresh water enters the ultrafiltration liquid tank, and then introduced into the electrodialysis system, after the inorganic salt is concentrated, the fresh water enters the reverse osmosis system, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com