High-efficiency integral aerating device for sewage treatment

An aeration device and sewage treatment technology, applied in the direction of biological water/sewage treatment, water/sludge/sewage treatment, sustainable biological treatment, etc., can solve the problems of high energy consumption and low efficiency, and achieve the goal of simplifying the power source Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Now how the present invention is implemented in conjunction with the accompanying drawings:

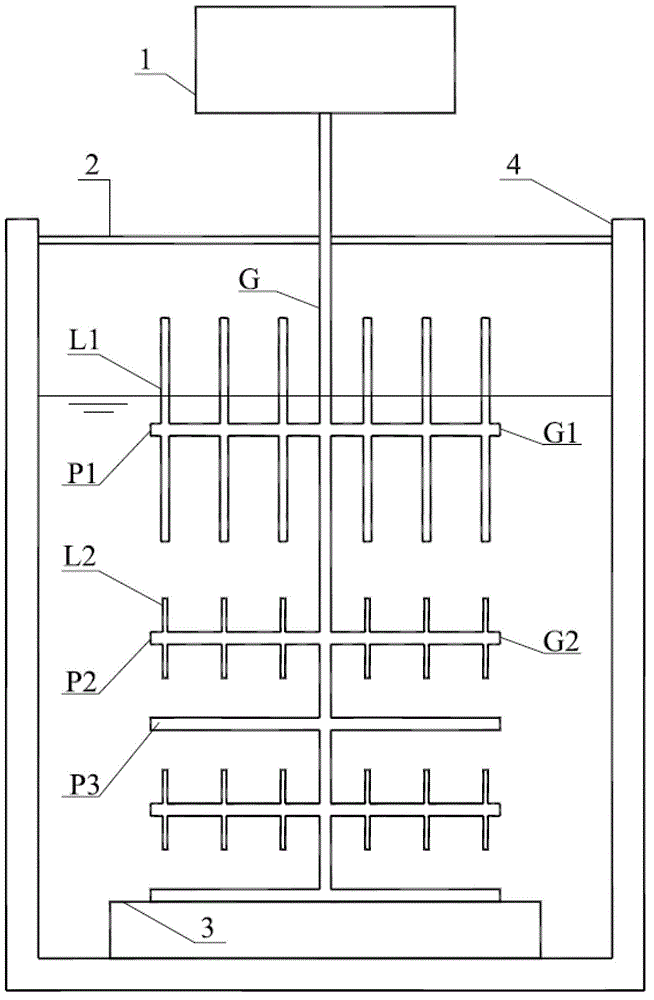

[0026]The integrated aeration device is composed of air compressor 1, compressed air main pipe G and compressed air branch pipes G1 and G2, two rows of aeration rotor row P1, two rows of stirring rotor row P2, two groups of micro The hole aeration ring tube group P3 is composed. The row of aeration rotors P1 and the row of agitating rotors P2 are arranged in a straight line and are perpendicular to the compressed air main pipe G and are symmetrically cross-connected. P1 is located at the upper part of compressed air main pipe G. The stirring wheel row P2 and the microporous aeration ring pipe group P3 are located at the lower part of the compressed air transmission main pipe G, and are arranged alternately at equal intervals from top to bottom in the order of P2, P3, P2, and P3. The main compressed air pipeline G is arranged vertically, and the compressed air branch pipes G1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com