Method for recycling high concentration ammonia nitrogen and making ammonia nitrogen into large granule high purity struvite

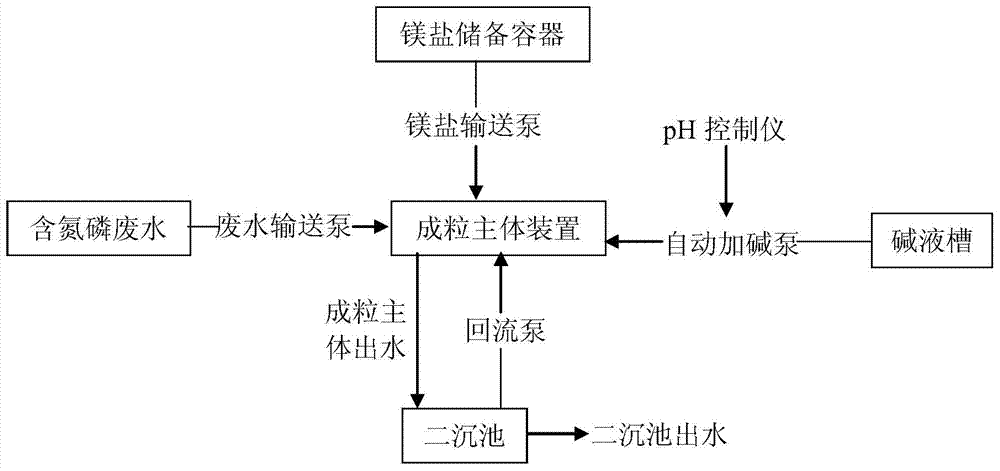

A technology of ammonia nitrogen recovery and struvite, applied in water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problem of low efficiency per unit time of struvite growth and inability to remove nitrogen and phosphorus Recycling and utilization of nitrogen and phosphorus wastewater, resulting in loose particle structure and other problems, to achieve the effects of saving chemical costs, facilitating fluidized growth, and reducing the amount of magnesium salts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

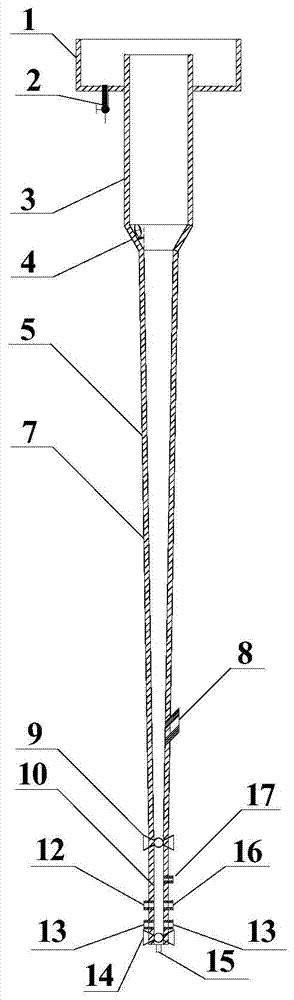

Method used

Image

Examples

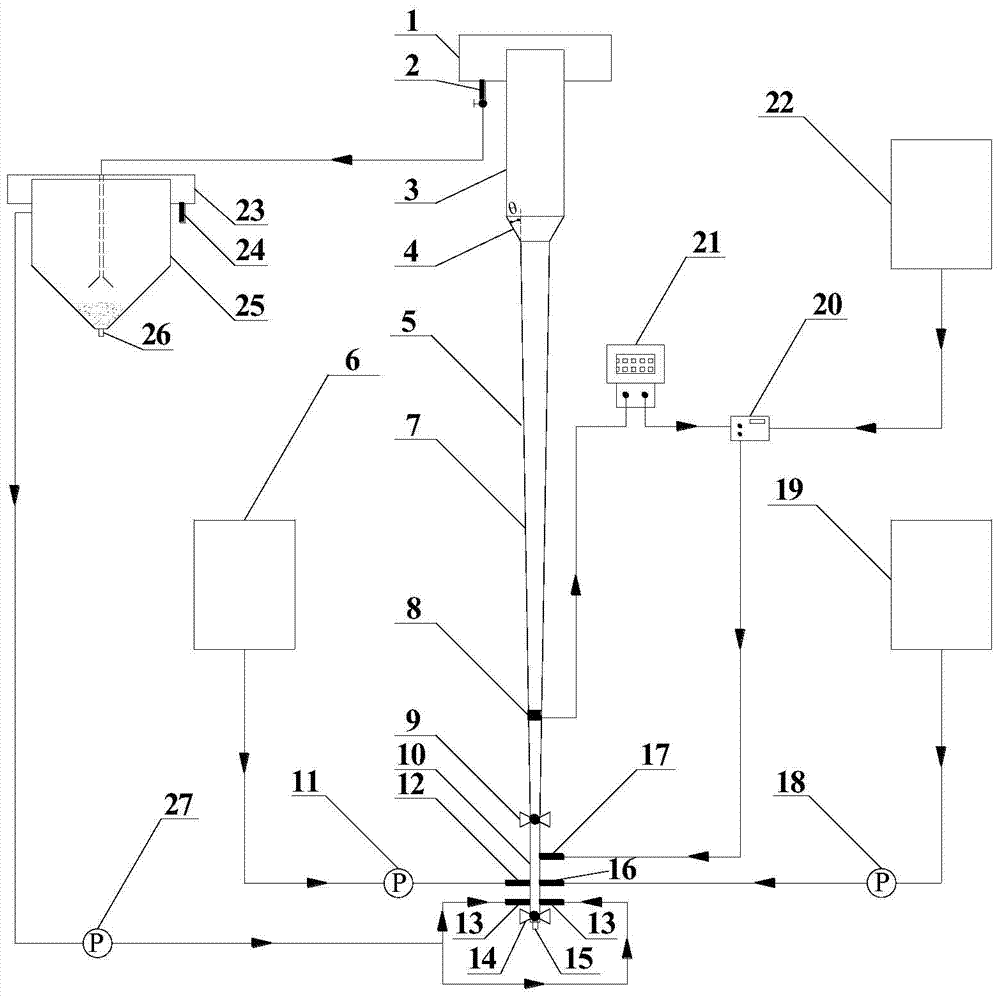

Embodiment 1

[0034] Simulation of synthetic ammonia wastewater NH 4 + -N concentration is 1000mg / L, that is, firstly pump 1 ton of synthetic ammonia waste water into nitrogen and phosphorus waste water tank 19, add 3.821 kg of ammonium chloride solid into waste water tank 19, and then add synthetic ammonia waste water into 17.048 kg of disodium hydrogen phosphate solid In this case, the NH in the simulated wastewater 4 + -N concentration is 1000mg / L, PO 4 3- -P concentration is 1500mg / L (maintain NH 4 + -N:PO 4 3- -P molar ratio 1.5:1). Configure a magnesium chloride solution with a concentration of magnesium ions of 1260mg / l (that is, add 10.63kg of magnesium chloride solid to 1t of water), and the magnesium salt impeller pump 11 will MgCl 2 The solution is pumped into the granulation body 5 through the magnesium salt inlet 12 according to the molar ratio of N:P:Mg=1.5:1:1.1, and the synthetic ammonia wastewater in the nitrogen-phosphorous wastewater tank 19 is passed through the...

Embodiment 2

[0037] Using this method to deal with NH 4 + - An industrial wastewater with a N concentration of 1373 mg / L, and the pH of the wastewater is about 4.9. First, 1 ton of water is pumped into the nitrogenous and phosphorus-containing wastewater tank 19, and 23.406 kg of disodium hydrogen phosphate solid is added to the nitrogenous and phosphorus-containing wastewater tank 19, that is, the NH in the phosphorus-containing wastewater tank 4 + -N concentration is 1373mg / L, PO 4 3- -P concentration is 2027mg / L (maintain NH 4 + -N:PO 4 3- -P molar ratio 1.5:1), configure a magnesium chloride solution with a concentration of magnesium ions of 1883mg / l, that is, add 15.93kg of solid magnesium chloride to 1 ton of water, and pump NH 4 + -N:PO 4 3- -P:Mg 2+ The molar ratio is 1.5:1:1.2. Open the pH adjustment pump 20, and the NaOH solution in the lye tank 22 is also pumped into the granulation main body 5 through the alkali addition port 17, and the pH value in the granulation...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com