Device and method for strengthening sludge digestion and synchronously denitrifying and dephosphorizing

A simultaneous denitrification and dephosphorization and sludge removal technology, applied in chemical instruments and methods, water/sludge/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of increasing the solid load of subsequent treatment units and large washing water volume , Sludge-water separation difficulties and other problems, to achieve the effect of weakening substrate inhibition, less sludge production, and stable denitrification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail in conjunction with the accompanying drawings and embodiments.

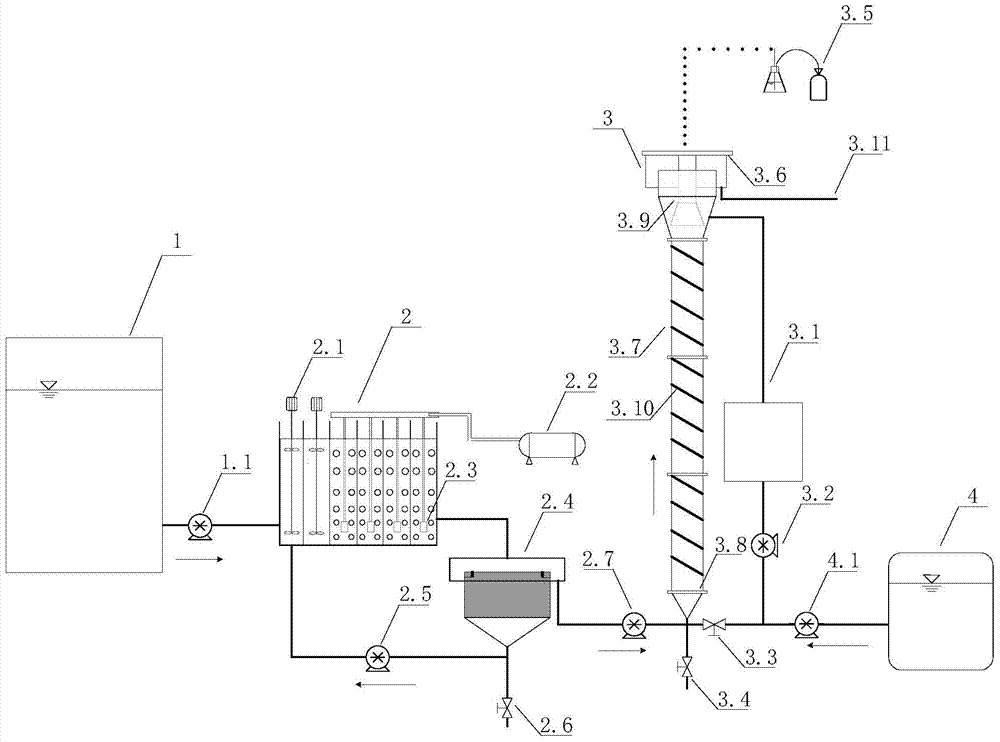

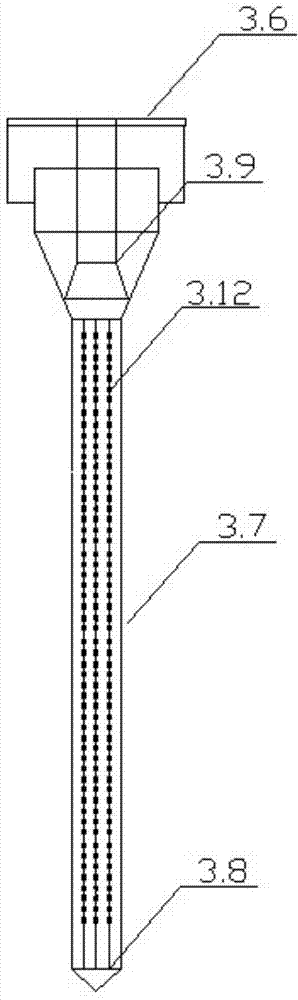

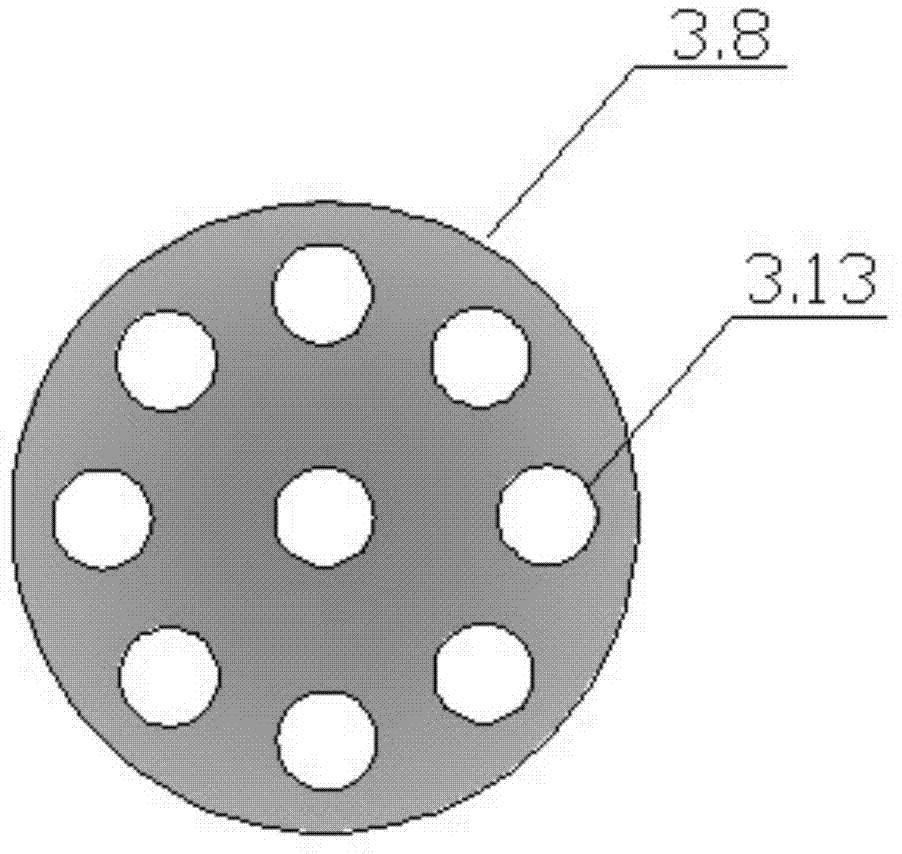

[0035] Such as figure 1 , figure 2 , image 3 As shown, the device for strengthening sludge digestion and synchronous nitrogen and phosphorus removal includes raw water tank 1, raw water inlet pump 1.1, A-O reactor 2, stirring device 2.1, air compressor 2.2, aeration head 2.3, sedimentation tank 2.4, sewage Mud return pump 2.5, mud discharge valve 2.6, outlet pump 2.7, SFDANR reactor 3, intermediate water tank 3.1, circulation pump 3.2, circulation control valve 3.3, emptying valve 3.4, gas collection device 3.5, sealing plate 3.6, cylindrical sewage Mud bed 3.7, water distribution device 3.8, three-phase separator 3.9, heating belt device 3.10, outlet pipe 3.11, sponge filler 3.12, water distribution hole 3.13, mud storage tank 4, mud inlet pump 4.1.

[0036] The raw water tank 1 is connected to the A-O reactor 2 through the raw water inlet pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com