Novel anaerobic fermentation equipment and method for sludge

A new type of sludge anaerobic fermentation technology, applied in biological sludge treatment, waste fuel and other directions, can solve the problems of slow sludge fermentation, low work efficiency, uneven stirring, etc., to improve fermentation speed and fermentation effect, fermentation Fast speed and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

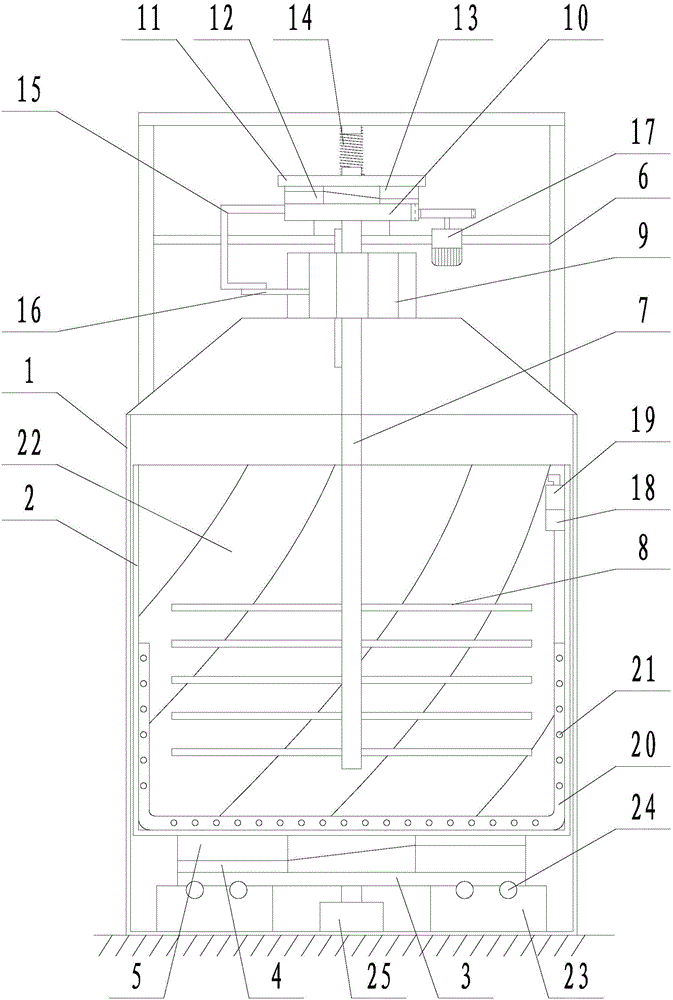

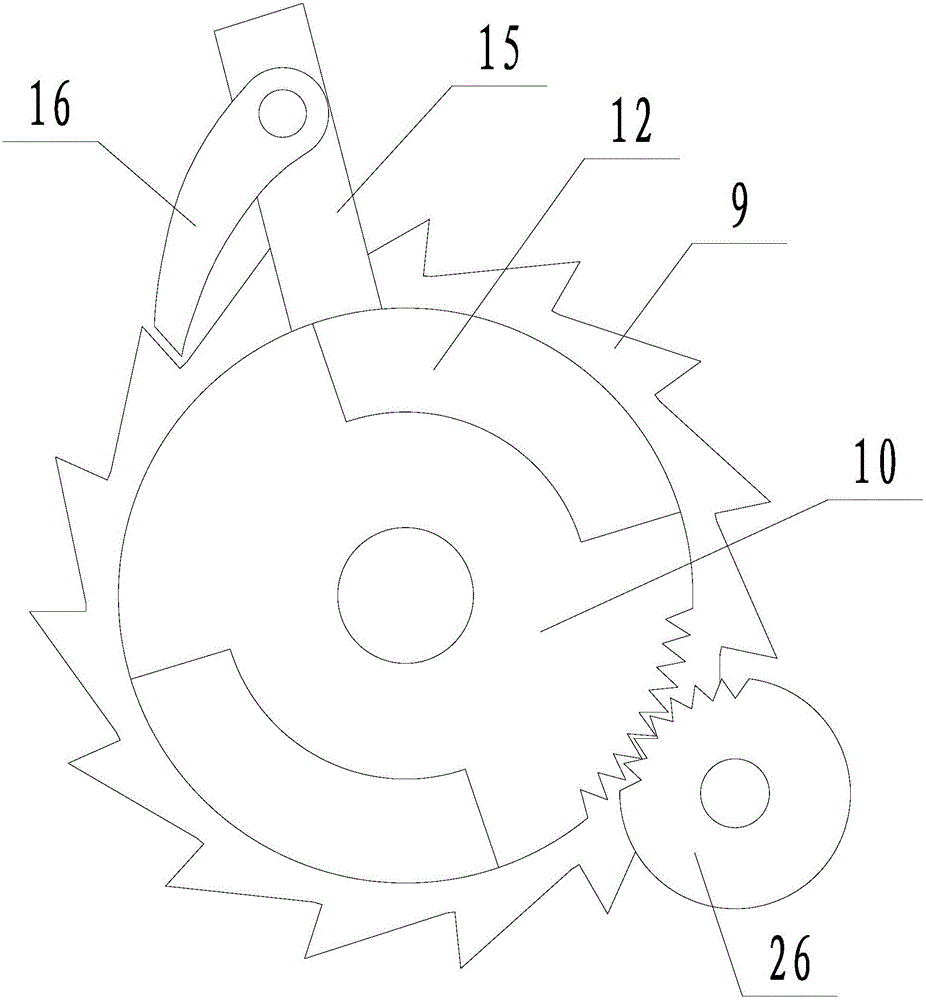

[0018] Embodiment: a kind of novel sludge anaerobic fermentation equipment (see attached figure 1 , attached figure 2 ), including a fermenter 1 in which a fermenter 2 is socketed, and the upper end of the fermenter has a conical structure with a small top and a big bottom. A turntable 3 is installed on the inner bottom of the fermentation tank, and two arc-shaped wedge-shaped protrusions 4 are evenly distributed on the upper surface of the turntable. Correspondingly, there are two arc-shaped abutting convex strips 5, and the lower surface of the abutting convex strips is inclined downward along the counterclockwise direction; a bracket 6 is installed on the fermentation tank, and a stirring shaft 7 is arranged in the fermentation cylinder to stir The lower end of the shaft is connected with a stirring blade 8, the upper end of the stirring shaft is axially slidable and is fitted with a ratchet 9 for radial limit, a pusher 10 is movably sleeved above the ratchet on the stirr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com