Control method and method for treating sludge digestion liquid through sludge-fermentation-coupled denitrification

A sludge digestion solution and control device technology, applied in water/sludge/sewage treatment, chemical instruments and methods, multi-stage water/sewage treatment, etc., to improve control efficiency, strengthen fermentation and denitrification effects, prolong Effect of solid residence time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

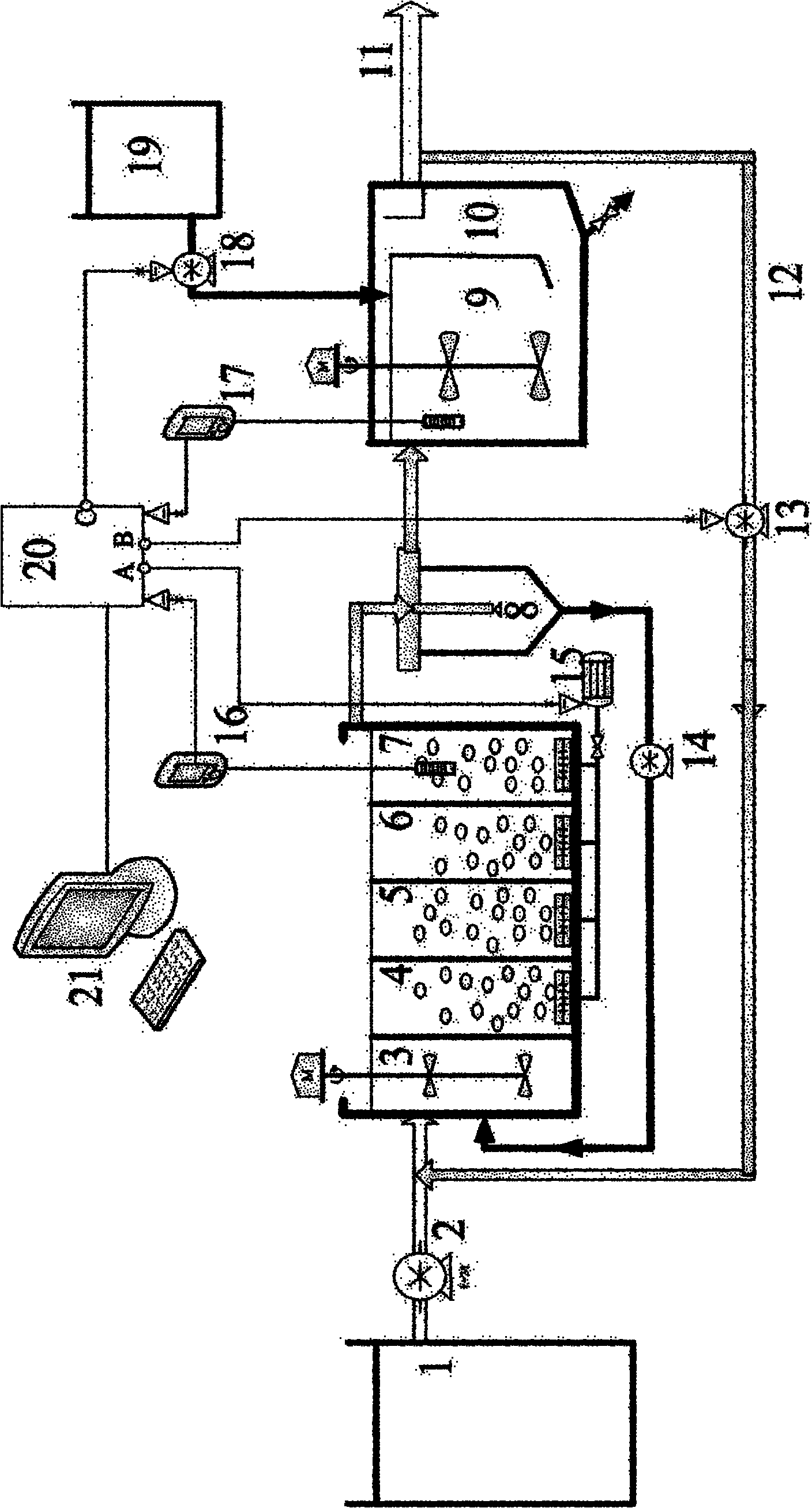

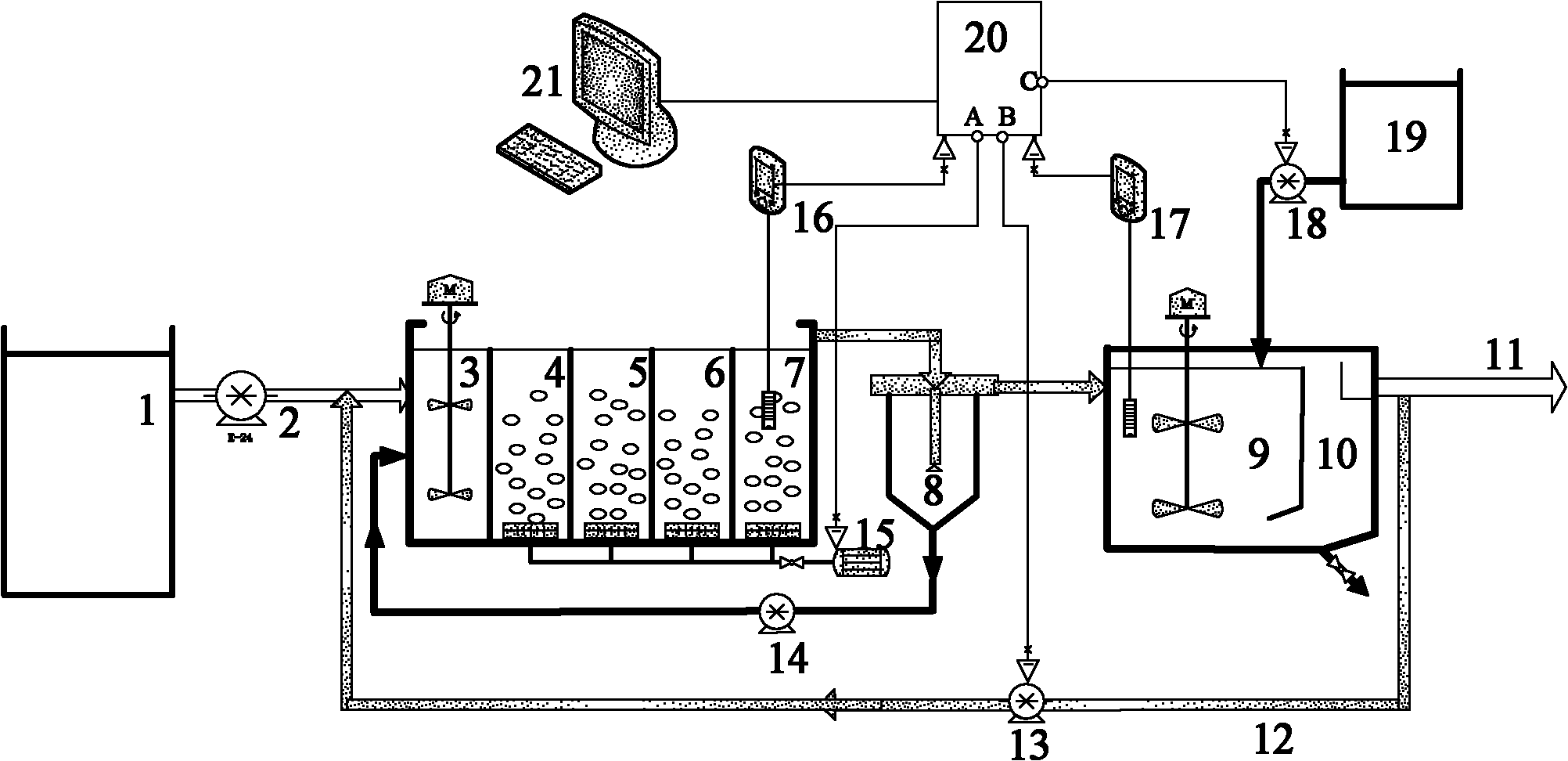

[0022] In conjunction with the accompanying drawings and embodiments, the patent application is further described: as figure 1As shown, the sludge fermentation coupled denitrification device of the present invention comprises a raw water tank 1 for sludge dehydration liquid, nitrification reactors 3-7, sedimentation tank 8, and sludge fermentation coupled denitrification reactors 9-10. Raw water tank 1 is 400L, and the nitrification reactor is a single corridor reactor with plexiglass texture, with an effective volume of 36L, of which the volume of the anoxic reactor is 4L, and the volume of the aerobic reactor is 8L. The aerobic reactor provides aeration through an air compressor, and the aeration head adopts a gravel aeration head. In order to avoid back mixing between the aerobic reactors, each reactor is separated by a partition, and a connecting pipe is arranged at a suitable position on the partition. The effective volume of the reaction zone 9 of the sludge fermentatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com