Planting soil and preparation method thereof

A technology for fermenting bacteria and sludge, applied in the field of planting soil and its preparation, can solve the problems of polluted environment, large demand for foreign soil, occupation of land resources, etc. , to achieve the effect of resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

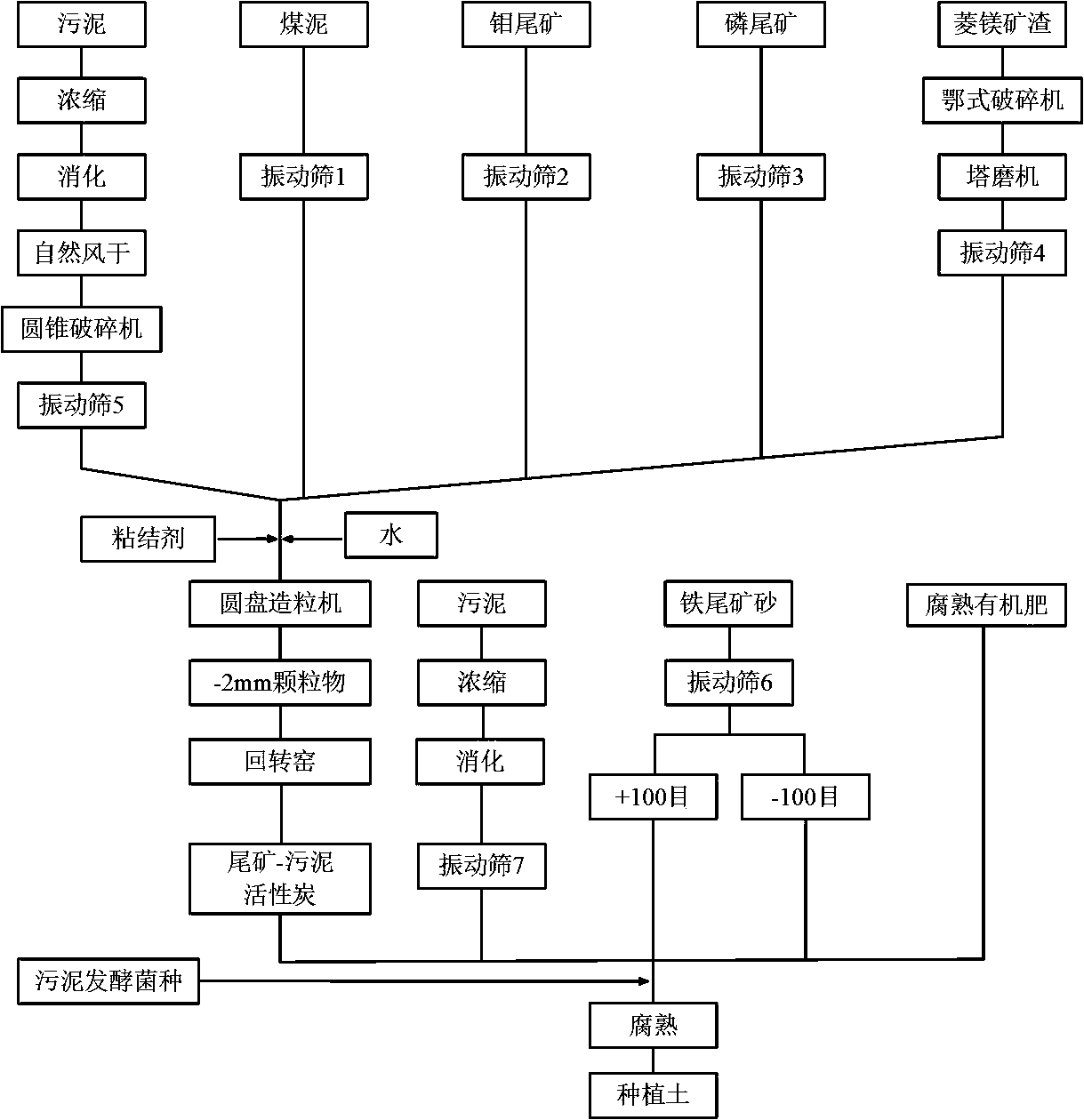

[0038] A preparation method of planting soil, comprising the following steps:

[0039] (1) Combine sludge, iron tailings, decomposed organic fertilizer, tailings-sludge activated carbon according to mass ratio: sludge 100~120: iron tailings 40~50: decomposed organic fertilizer 10~15: tailings-sludge Activated carbon 20~30 and mix well to get the mixture;

[0040] (2) Add the sludge fermentation bacteria into the mixture, mix evenly, and decompose for 10 to 15 days to obtain planting soil.

Embodiment 1

[0042] A kind of planting soil and preparation method thereof, comprises the following steps:

[0043] (1) Send the sludge to the thickener for dehydration and digestion, and then send it to the vibrating screen for screening to obtain the sludge raw material under the -10 mesh sieve;

[0044] (2) Send the iron tailings sand to the vibrating screen for screening to obtain +100 mesh iron tailings sand and -100 mesh iron tailings sand, and then mix the +100 mesh iron tailings sand and -100 mesh iron tailings sand according to the mass ratio: +100 mesh iron tailings sand 3: -100 mesh iron tailings 1.2 are mixed evenly to obtain iron tailings compound ingredients;

[0045] (3) Send the sludge to a thickener for concentration and dehydration, digestion, and natural air-drying, then send it to a cone crusher for crushing, and then sieve it through a vibrating screen to obtain sludge raw materials under a -10 mesh sieve; magnesite slag Send it to the jaw crusher for crushing, then s...

Embodiment 2

[0050] A kind of planting soil and preparation method thereof, comprises the following steps:

[0051] (1) Send the sludge to the thickener for dehydration and digestion, and then send it to the vibrating screen for screening to obtain the sludge raw material under the -10 mesh sieve;

[0052] (2) Send the iron tailings sand to the vibrating screen for screening to obtain +100 mesh iron tailings sand and -100 mesh iron tailings sand, and then mix the +100 mesh iron tailings sand and -100 mesh iron tailings sand according to the mass ratio: +100 mesh iron tailings 3.2: -100 mesh iron tailings 1.1 are mixed evenly to obtain iron tailings compound ingredients;

[0053] (3) Send the sludge to a thickener for concentration and dehydration, digestion, and natural air-drying, then send it to a cone crusher for crushing, and then sieve it through a vibrating screen to obtain sludge raw materials under a -10 mesh sieve; magnesite slag Send it to the jaw crusher for crushing, then send...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com