Process for preparing fresh scent strong-flavor Chinese spirit

A kind of Luzhou-flavor liquor and its preparation technology, which is applied in the preparation technology of liquor fermentation cellar mud and the field of liquor fermentation and brewing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Sludge preparation

[0033] (1) Material pretreatment:

[0034] Yeast slime production method: add alcohol dry yeast powder to 10 times 8% sucrose water, stir well, and activate into yeast slime at 37°C for 20 minutes;

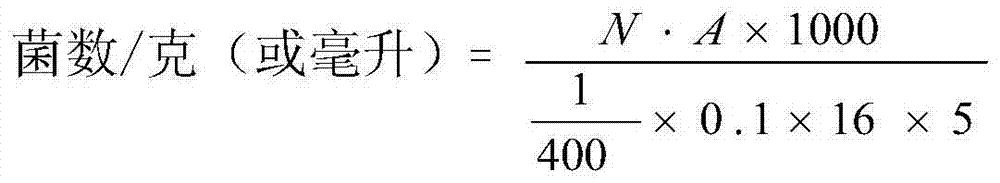

[0035] Pig blood, bean cake powder or silkworm chrysalis powder fermentation method, pig blood is directly added with alcohol yeast mud, bean cake powder or silkworm chrysalis powder soaked in 5 times of water for 1 day, then add the above yeast mud, the amount of yeast mud is soaked in pig blood, bean cake soak or silkworm chrysalis powder 1% of the weight of the product, fermented at room temperature for more than 30 days, and the yeast content is more than 20 million / ml;

[0036] (2) Methane bacteria liquid culture:

[0037] The leftovers of the biogas tank are used as the bacterial species, and the amount of the species used is more than 15% by weight. The medium formula includes the following components in parts by weight: 0.8 parts of ammonium ...

Embodiment 2

[0047] Preparation of koji

[0048] (1) Raw material crushing

[0049] The crushing of raw materials has a great relationship with the quality of wheat koji. After the raw materials are cleaned of impurities, 5%-10% warm water should be added and mixed well before crushing. After 12 hours of moistening, the crushing degree of raw materials should be strictly controlled. Wheat is ground into "rotten heart and rotten skin" plum petals, that is, the wheat skin is ground into flakes, and the heart is ground into powder.

[0050] (2), add water and mix

[0051] The raw material powder after raw material crushing contains only about 15% moisture, which cannot meet the needs of koji forming and bacteria cultivation. Therefore, water needs to be added to the mixing material. The amount of water added and whether the mixing is uniform are related to the quality of wheat koji. The necessary substance for the biochemical reaction is the solvent inside and outside the microorganisms. On...

Embodiment 3

[0059] Fermentation wine making process

[0060] 1. The production process of Xiaoqu Liquor:

[0061] 1. Soaking grain: absorb water thoroughly and evenly, and soak in enough water. The temperature of the soaked grain is 73-74°C after stirring. The soaking time is 6-10 hours.

[0062] 2. Steamed food: the cooked food is required to be tender, light, sweat-absorbing and even. When out of the retort, the water content is 59-61%, and the starch crack rate is over 89%.

[0063] 3. Bacteria culture in the box:

[0064] Requirement A: Mold and yeast grow normally, and there are few miscellaneous bacteria. Out of the box senses: velvet, with koji fragrance, no rancidity, stuffiness, or alcohol smell, and the temperature, time and aging of the out-of-box are strictly controlled.

[0065] B After closing the box, the temperature inside the box is close to room temperature in hot season, and generally 30-31°C in winter. After 25-26 hours of cultivation in cold weather and 21-22 ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com