Polymer supported Pd-Ni-B nano-catalyst, preparation method and application thereof

A nano-catalyst, polymer-supported technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve problems such as high price and limited Ru metal storage , to achieve the effect of easy separation and high hydrogen yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

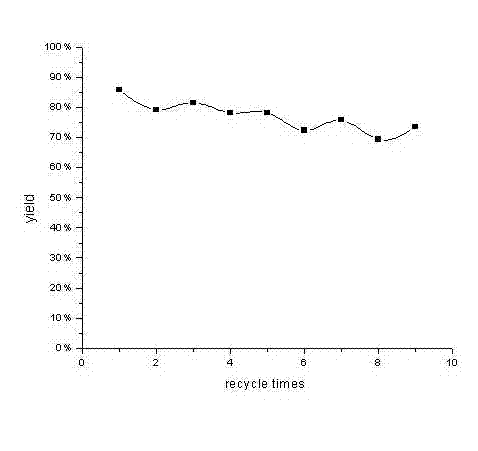

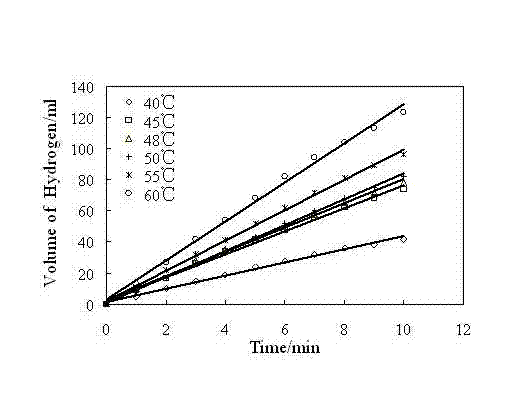

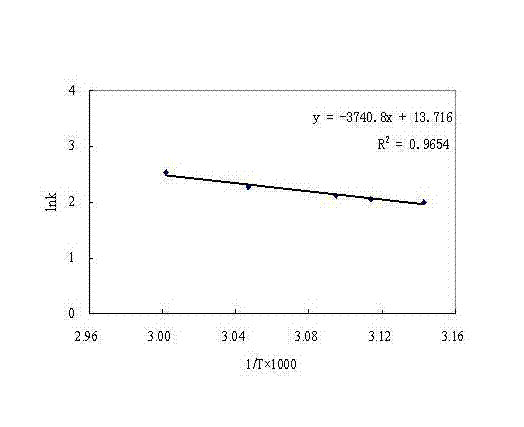

Examples

Embodiment 1

[0041] Embodiment 1: the preparation mode of Pd-Ni-B nano-catalyst of the present invention, comprises the following steps:

[0042] 1. Preparation of PVP solution:

[0043] Weigh 2.5g of polyvinylpyrrolidone (PVP) into a beaker, add 20mL of distilled water to dissolve it, and then add 20mL of PdCl prepared in advance 2 -HCl (200 mg PdCl 2 +200mL 0.5 mol / L HCl solution) and 20 ml NiSO 4 solution (0.59 g NiSO 4 ·7H 2 O and 20mL distilled water), and slowly add NaBH dropwise with stirring 4 solution (0.172 g NaBH 4 + 20mL distilled water), the reaction was complete.

[0044] 2. Preparation of acrylamide solution:

[0045] Take 7.82 g of acrylamide, add 0.93 g of N,N'-methylenebisacrylamide (MBAM) as a cross-linking agent, 0.15 g of potassium persulfate as an initiator, and 20 mL of distilled water as a solvent, stir and let stand to dissolve the solid .

[0046] 3. Mixing:

[0047] Mix the two solutions prepared in step 1 and step 2 in a beaker, put the mixed solution ...

Embodiment 2

[0050] The preparation method is the same as in Example 1, the difference is that: increase the amount of Pd used, so that PdCl 2 The amount of substance and NiSO 4 The ratio of the amount of substances is 1:5.

[0051]

Embodiment 3

[0053] The preparation method is the same as in Example 1, the difference is that: increase the amount of Pd used, so that PdCl 2 The amount of substance and NiSO 4 The ratio of the amount of substances is 1:10.

[0054]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com