Method for coupling rhamnolipid strengthened sludge pre-treatment and microorganism electrolysis to produce hydrogen

A technology of microbial electrolysis and rhamnolipid, which is applied in sludge treatment, immiscible solvent sludge treatment, water/sludge/sewage treatment, etc. Difficulty in breaking the walls of sludge flocs, etc., to achieve the effect of high yield of hydrogen per unit of sludge, increase of hydrogen yield of sludge, and promotion of hydrolysis and fermentation of sludge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

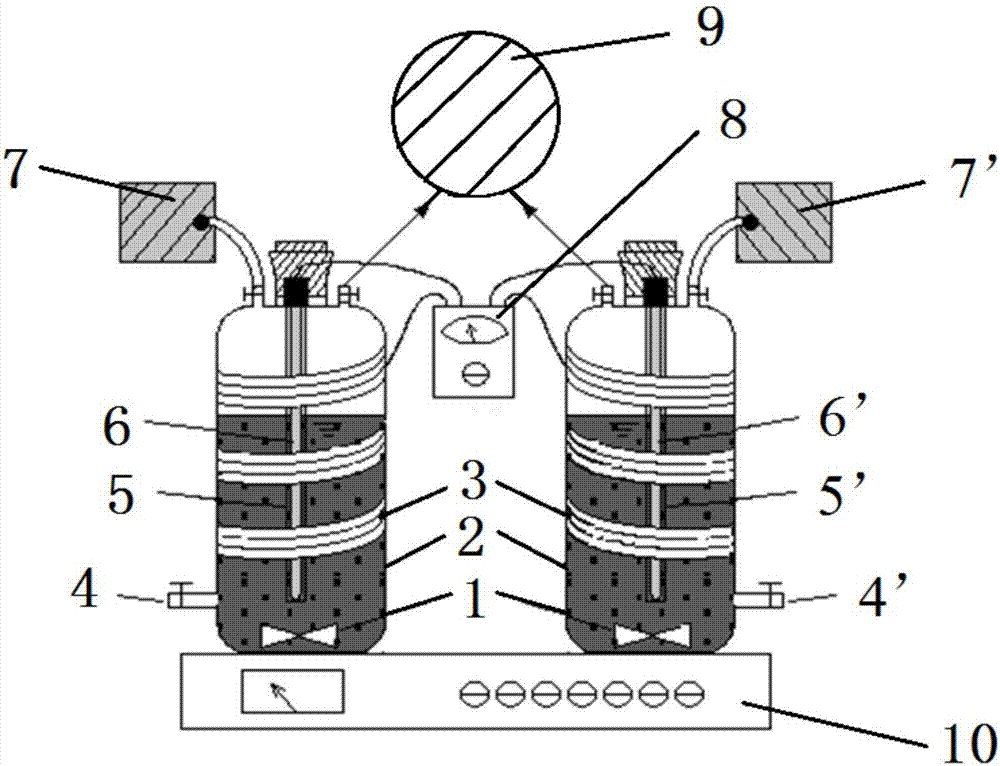

[0042] like figure 1 As shown, it is a schematic diagram of the sludge anaerobic fermentation acid production device, which consists of 1 rotor, 2 outer tin foil, 3 heating belt, 4, 4' inlet and outlet, 5, 5' temperature probe casing, 6 , 6' temperature probe, 7, 7' air bag, 8 temperature controllers, 9 nitrogen bags and 10 magnetic stirrers, the connection and assembly relationship is as follows figure 1 shown in .

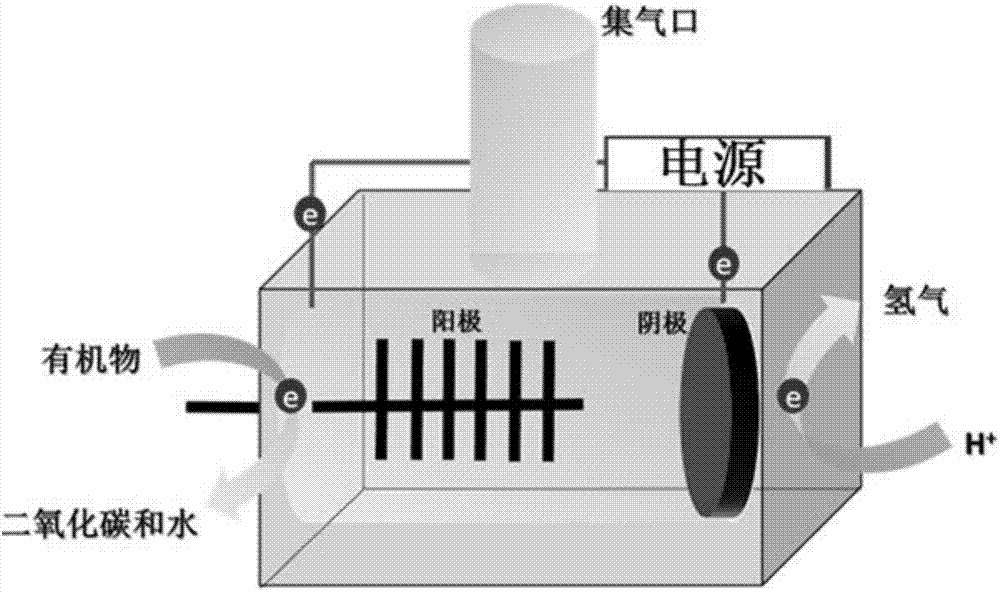

[0043] The method of rhamnolipid enhanced sludge pretreatment coupled with microbial electrolysis hydrogen production is carried out according to the following steps:

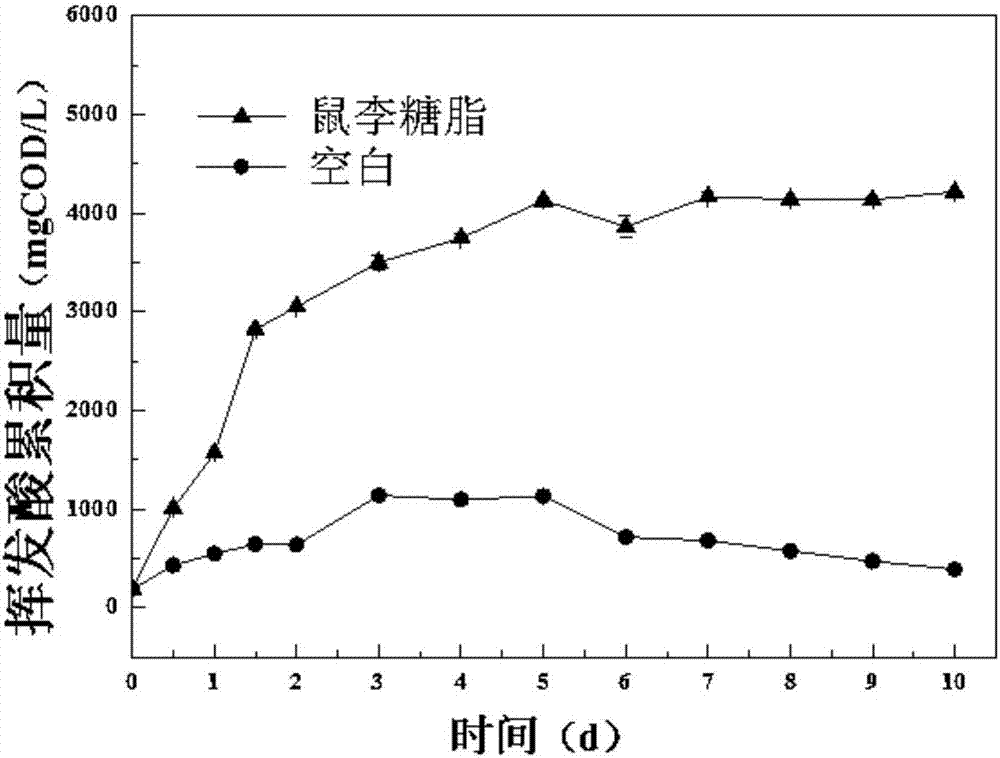

[0044] 1. Rhamnolipid pretreatment sludge: the remaining sludge in the secondary settling tank naturally settles for one day, removes the supernatant, adjusts the settled sludge concentration to 14g / L for later use, and adds rhamnolipid 0.04g / gVSS , refrigerate for later use.

[0045] 2. Fermentation of pretreated sludge to produce acid: Expose the sludge pretreated by rhamnolipid to nitrogen f...

specific Embodiment approach 2

[0047] Embodiment 2: The difference between this embodiment and Embodiment 1 is that step 1 can directly use the excess sludge without going through the settling process, and the others are the same as Embodiment 1.

specific Embodiment approach 3

[0048] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the rhamnolipid dosage concentration in step 1 can be 0.04-0.10 g / gVSS, and the others are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com