Nano-iron-loaded biochar, preparation method of nano-iron-loaded biochar, and application of nano-iron-loaded biochar in dark fermentation hydrogen production process

A biochar and dark fermentation technology, which is applied to nano iron-supported biochar and its preparation and application in the dark fermentation hydrogen production process, can solve the problems of low microbial concentration, low hydrogen yield, long fermentation lag period and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

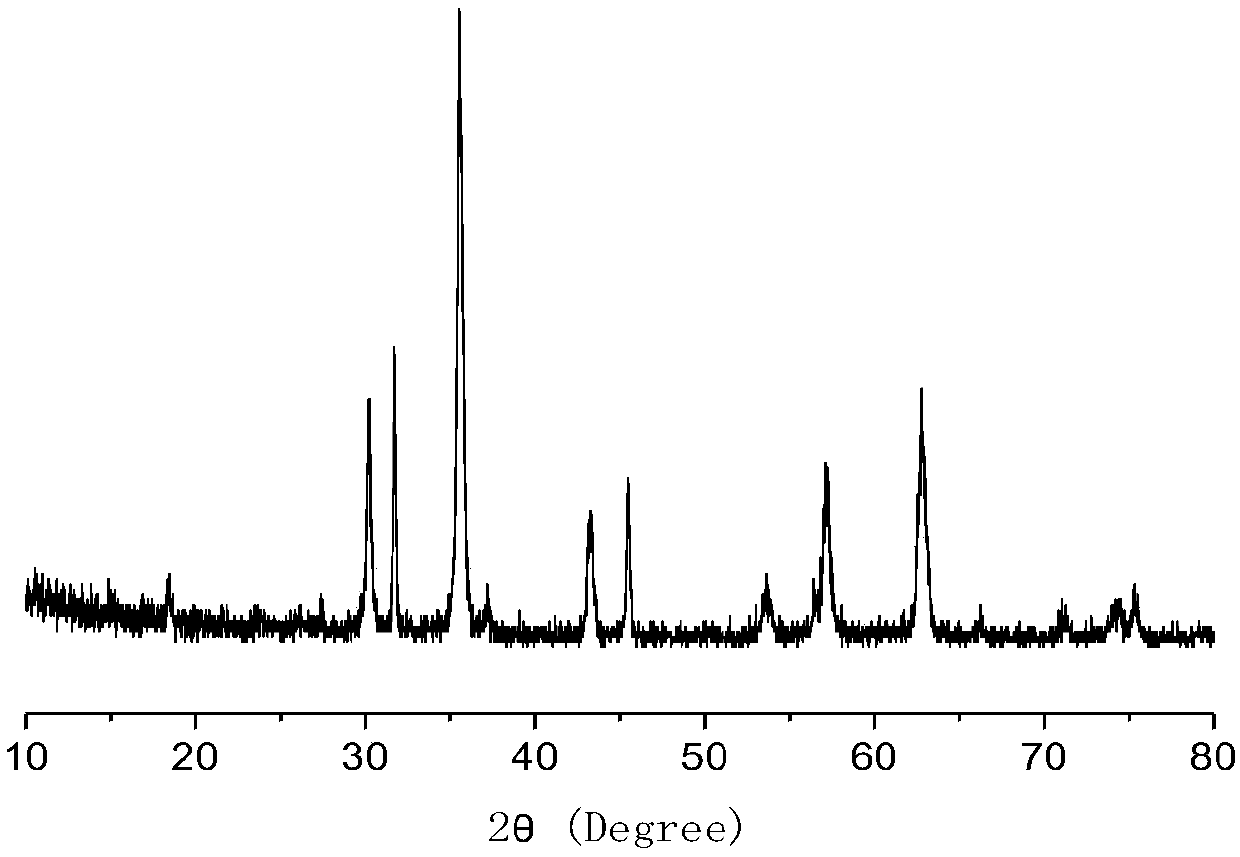

[0062] The preparation method of described iron-loaded biochar, concrete steps are as follows:

[0063] A. Add 40~80g FeCl 2 4H 2 O particles were dissolved in deionized water, and the volume was adjusted to 200ml with deionized water to obtain FeCl with a concentration of 128-256g / L 2 solution.

[0064] B. Dissolve 25-75g of soluble starch in 100-300ml of deionized water, and stir at 70-85°C for 15-30 minutes to obtain a uniform soluble starch solution with a concentration of 85-500g / L.

[0065] C. Mix the above ferrous solution and soluble starch solution at a volume ratio of 1:1-1.5, and stir them at 70-85° C. for 15-30 minutes to obtain a light blue solution.

[0066] D. Slowly add NaOH solution to the above light blue solution at 70-80°C until the reactant is alkaline (pH=10-12) and stir for 20-30min. At this time, the solution changes from light blue to yellow.

[0067] E. Stir the above yellow solution at 70-80°C and add H with a concentration of 0.7-1.5mol / L dropwi...

Embodiment 1

[0083] a. 45g FeCl 2 4H 2 O particles were dissolved in deionized water, and the volume was adjusted to 200ml with deionized water to obtain a concentration of 144g / L FeCl 2 solution.

[0084] b. Dissolve 50 g of soluble starch in 200 ml of deionized water, and stir at 80° C. for 15 minutes to obtain a uniform soluble starch solution with a concentration of 250 g / L.

[0085] c. Stir the above ferrous solution and soluble starch solution at a ratio of 1:1 at 80° C. for 30 min to obtain a light blue solution.

[0086] d. Constantly stir the above light blue solution in a water bath temperature control system (80° C.), slowly add 100 ml NaOH solution and stir for 25 minutes to adjust its pH to 11 to obtain a yellow liquid.

[0087] e. Stir the above yellow solution at 80°C and add H at a concentration of 1 mol / L dropwise. 2 o 2 Solution 45~50ml, stirring reaction for 1.5h to get black Fe 3 o 4 / Soluble starch suspension.

[0088] f. The above black Fe 3 o 4 / The solubl...

Embodiment 2

[0091] Others are the same as embodiment 1, the difference is:

[0092] a. 79g FeCl 2 4H 2 O particles were dissolved in deionized water, and the volume was adjusted to 200ml with deionized water to obtain FeCl with a concentration of 252g / L 2 solution.

[0093] b. Dissolve 80 g of soluble starch in 250 ml of deionized water, and stir at 80° C. for 20 minutes to obtain a uniform soluble starch solution with a concentration of 320 g / L.

[0094] c. Stir and mix the above ferrous solution and soluble starch solution at a ratio of 1:1.2 at 85° C. for 20 minutes to obtain a blue solution.

[0095] d. Stir the above light blue solution continuously in a water bath temperature control system (80° C.), slowly add NaOH solution to pH=12 and stir for 20 minutes to obtain a yellow liquid.

[0096] e. Stir the above yellow solution at 80°C and add H at a concentration of 1 mol / L dropwise 2 o 2 Solution 65 ~ 70ml, stirring reaction for 2h to get black Fe 3 o 4 / Soluble starch suspe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com