Method for improving hydrogen gas yield of kitchen waste anaerobic digestion

A technology for kitchen waste and anaerobic digestion, applied in biological sludge treatment, waste fuel, fermentation, etc., can solve the problem of high cost, and achieve the effect of reducing production cost, improving hydrogen yield and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

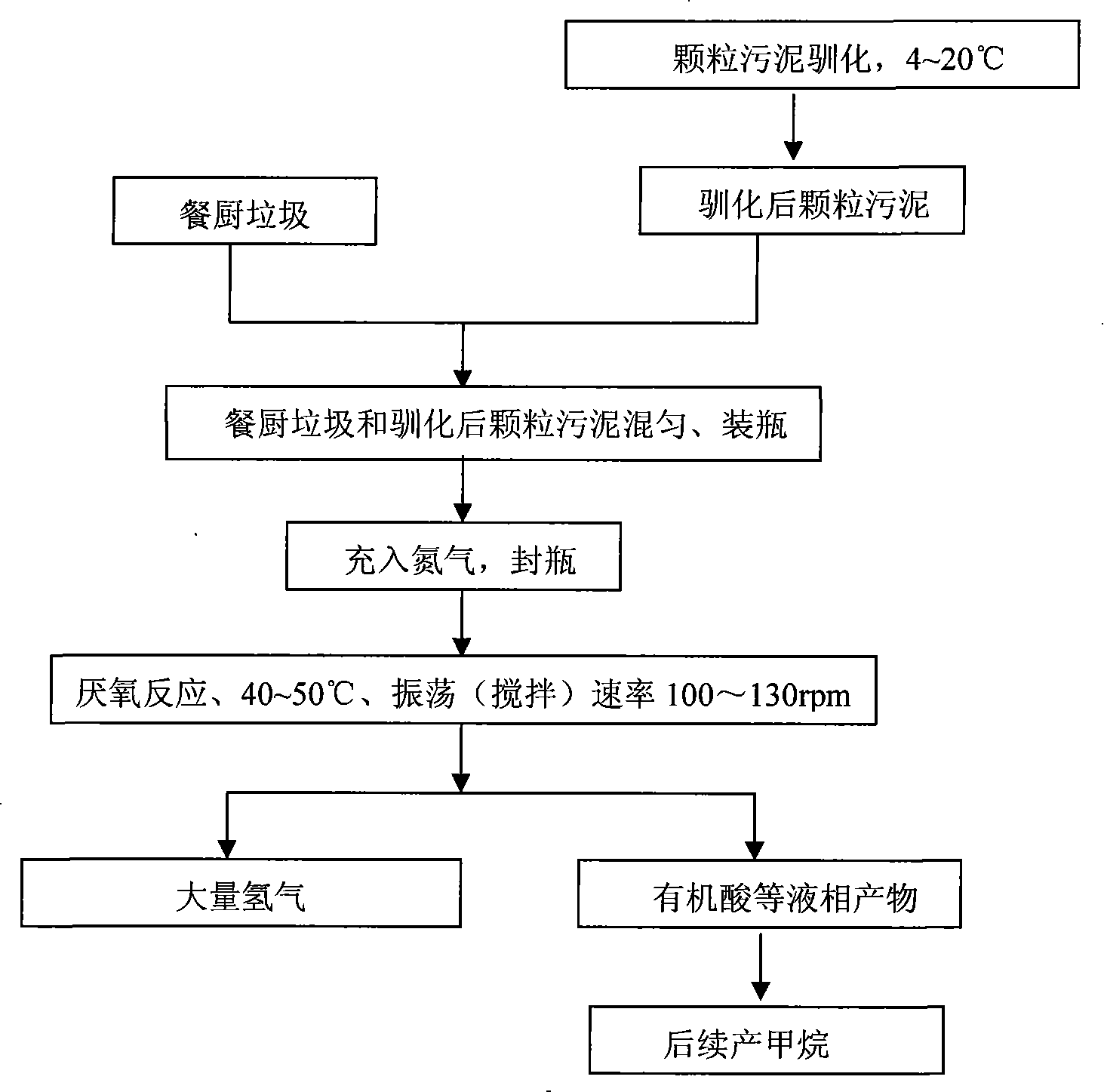

[0023] Please refer to the attached figure 1 .

[0024] The granular sludge was acclimatized before the experiment. The domestication step is as follows: granular sludge: food waste = 1 dry weight: 0.2-0.4 dry weight, put the granular sludge in a glass bottle, add food waste and fill the bottle with nitrogen or argon, Seal the mouth of the bottle and culture it statically at 4-20°C. When the pH drops to 4.5-5.5, the acclimatization is over and it is ready for use. In order to better understand the effects of heat treatment and non-heat treatment methods on hydrogen production under the process conditions, a control group and an experimental group were set up in this experiment.

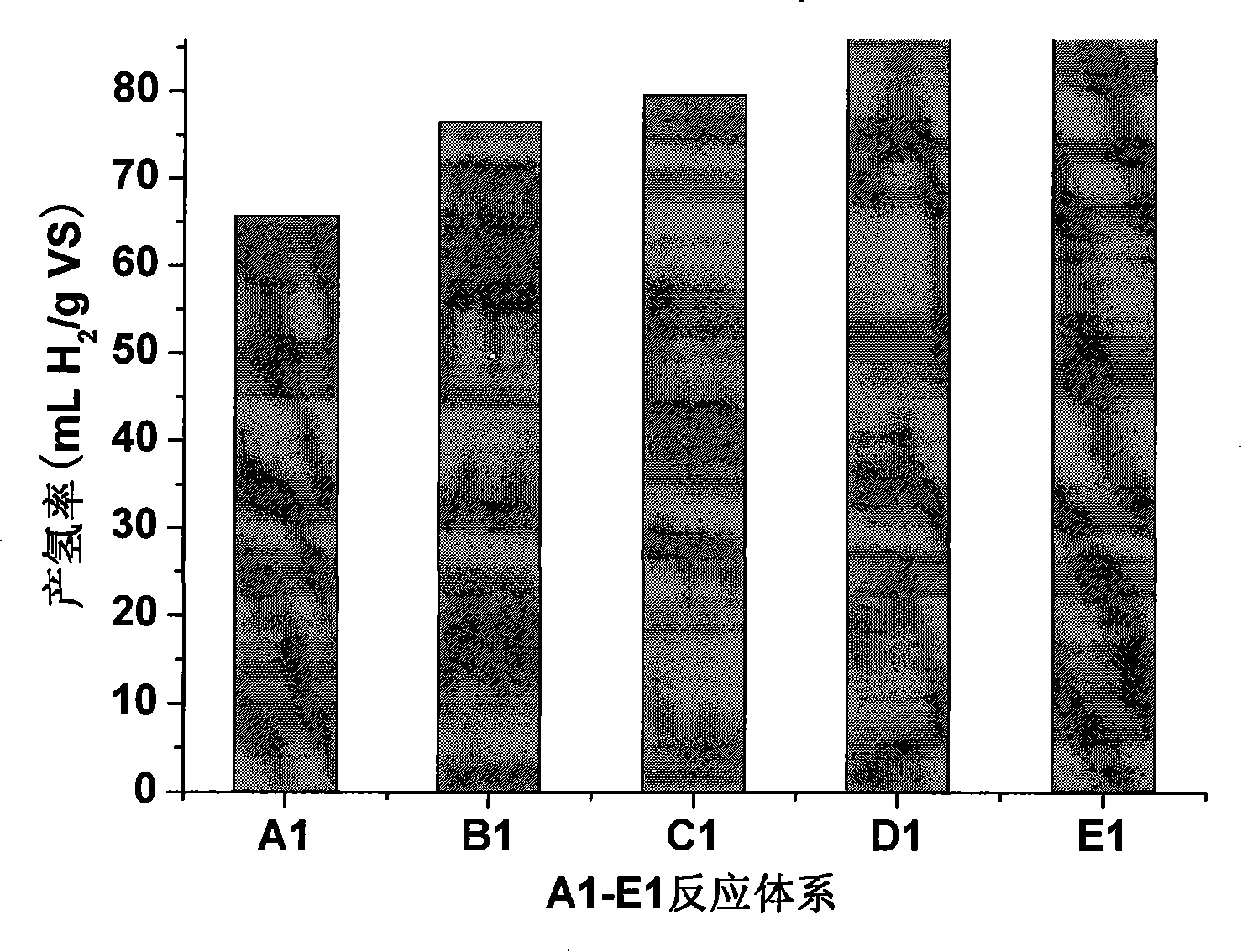

[0025] The experimental group took five 300ml serum bottles, weighed 7.8 g (dry weight) of broken kitchen waste in each bottle, and then filled each bottle with 0.46, 0.92, 1.38, 1.84, and 2.30 g of domesticated waste. mud (dry weight), and then add distilled water to each bottle to adjust the conc...

Embodiment 2

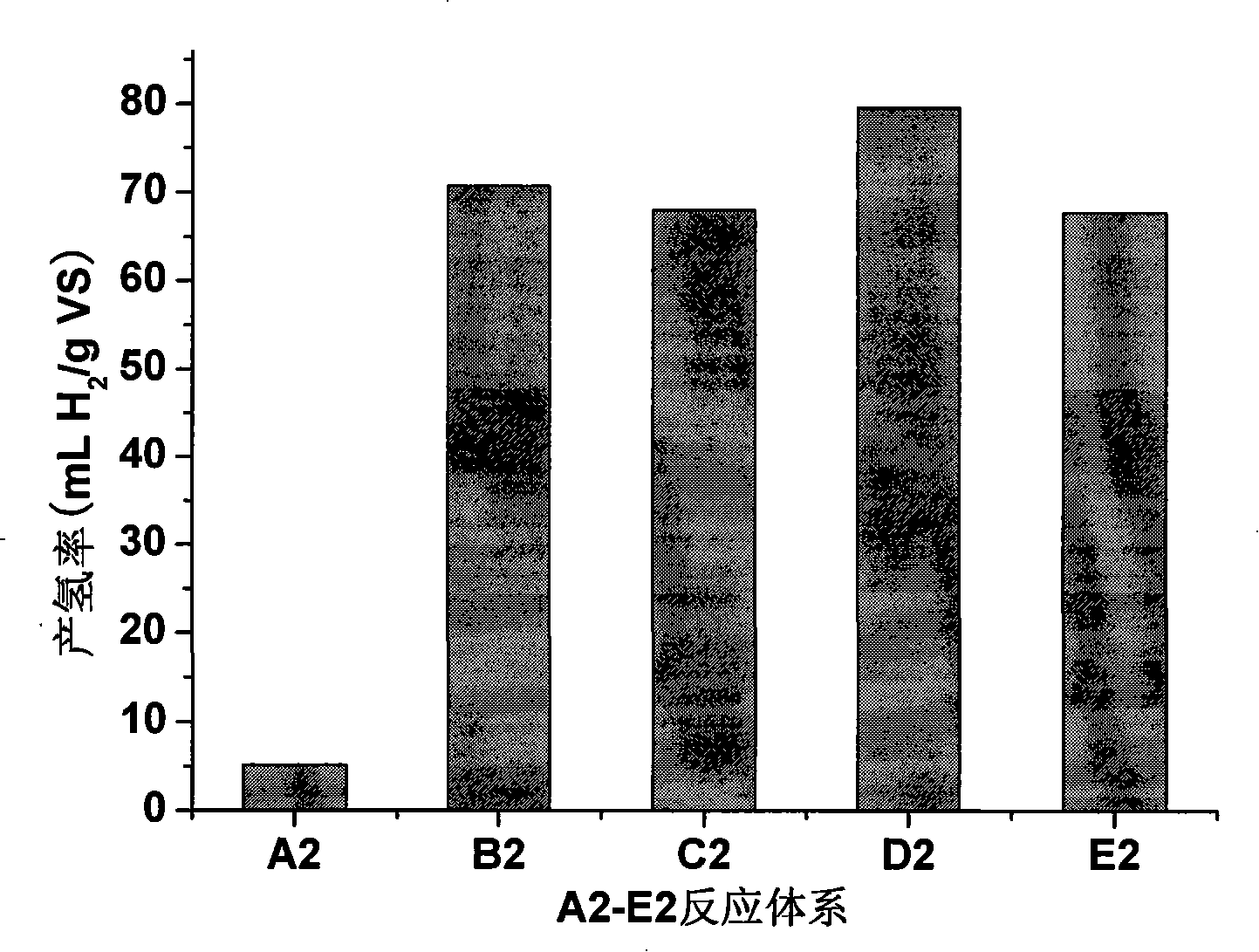

[0032] The granular sludge was acclimatized before the experiment. The domestication step is as follows: granular sludge: food waste = 1 dry weight: 0.2-0.4 dry weight, put the granular sludge in a glass bottle, add food waste and fill the bottle with nitrogen or argon, Seal the mouth of the bottle and culture it statically at 4-20°C. When the pH drops to 4.5-5.5, the acclimatization is over and it is ready for use. In order to better understand the effects of heat treatment and non-heat treatment methods on hydrogen production under the process conditions, a control group and an experimental group were also set up in this experiment.

[0033] The experimental group took five 300ml serum bottles, weighed 7.8g (dry weight) of broken kitchen waste in each bottle, and then filled each bottle with 0.46, 0.92, 1.38, 1.84, 2.30g of domesticated particles Sludge (dry weight), then fill with inert gas and seal the bottle. Place it in a constant temperature oscillation box at 40-50°C...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com