Method for producing hydrogen and/or methane through fermentation of fiber wastes and device thereof

A waste and methane production technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, biochemical cleaning devices, etc., can solve the problems of low raw material utilization, secondary pollution, and large energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

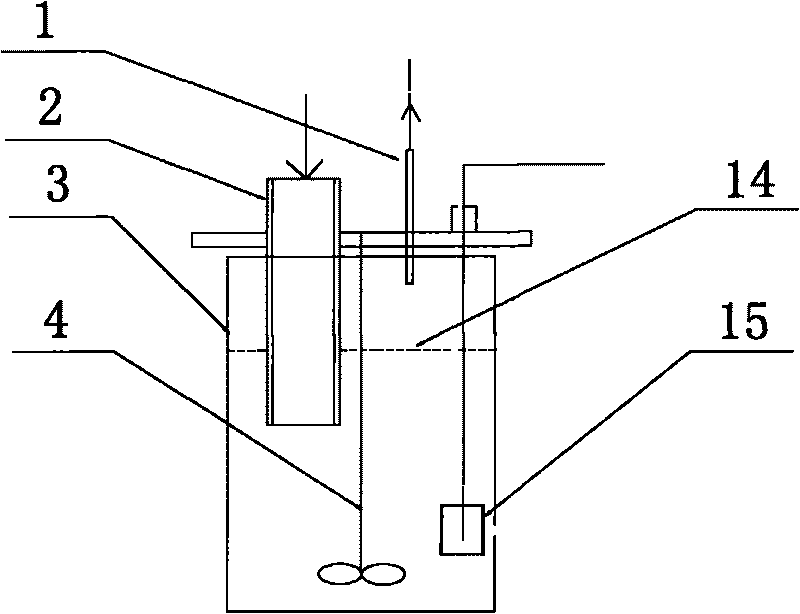

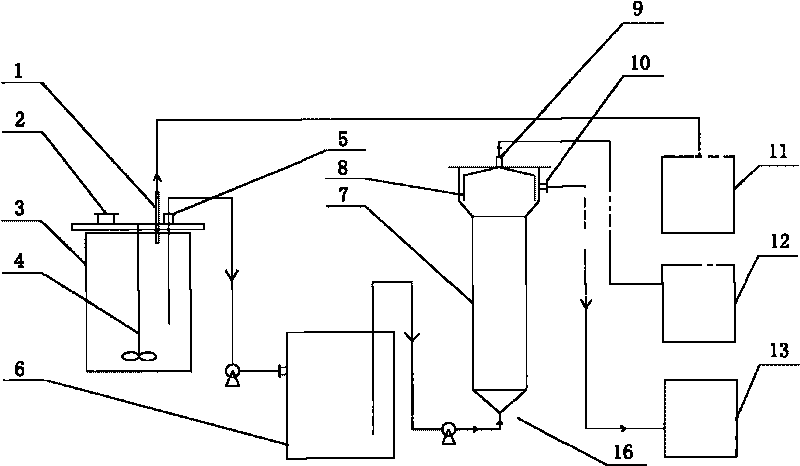

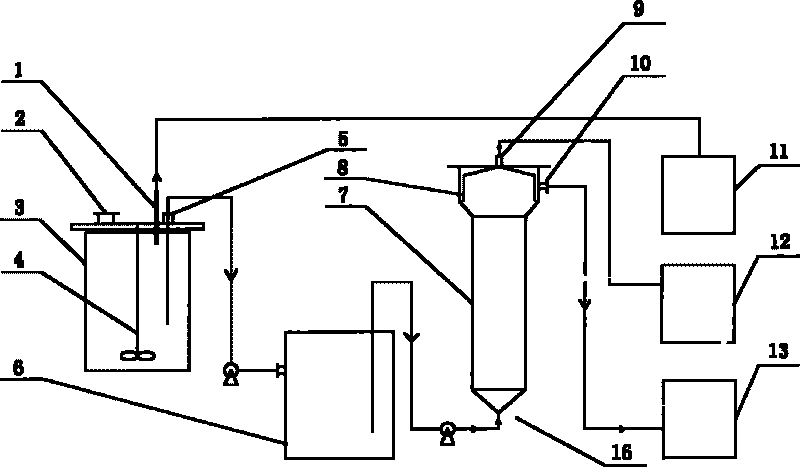

[0067] The present invention proposes a production device for two-stage fermentation of fiber waste to co-produce hydrogen and methane, which is used to produce hydrogen and methane. It includes: a hydrogen production reactor 3, which is a stirred reactor, and it passes through a pipeline and a liquid storage tank 6 It is connected to the hydrogen storage tank 11, and is provided with a hydrogen outlet 1, a hydrogen production feed port 2, a stirring device 4 and a hydrogen production discharge port 5; the methane production reactor 7 is an upflow sludge bed reactor (UASB), and its It is connected with liquid storage tank 6 , biogas slurry storage tank 13 and methane storage tank 12 through pipelines, and is provided with a methanogenic water outlet 10 and a methane outlet 9 .

[0068] The aforementioned two-stage fermentation co-production of hydrogen and methane production device for fiber waste, wherein a fence 14 is set at 10 mm below the fermentation liquid level of the hy...

Embodiment 2

[0084] The device used in this embodiment is the same as in Embodiment 1.

[0085] Corn stalks (taken from the suburbs of Daxing, Beijing), Clostridium thermocellum DSM No.1237 (purchased from the German Culture Collection), Clostridium thermocellum DSM No.4150 (purchased from the German Culture Collection), and thermal fiber Clostridium DSM No.7072 (purchased from the German Culture Collection) and mesogenic methane-producing sludge (prepared with reference to the method described in Example 1) are produced by two-stage fermentation of hydrogen and methane, the steps are as follows:

[0086] (1) Crushing and mixing of raw materials

[0087] Collect fiber waste raw materials, use a plant pulverizer to crush them to a particle size below 20mm, weigh a certain amount of solid raw materials and nutrient salt solution and add them to the hydrogen production reactor, wherein the concentration of solid fiber waste is 10g / L, and the nutrient salt solution Composition is with embodimen...

Embodiment 3

[0098] The device used in this embodiment is the same as in Embodiment 1.

[0099] Use sorghum straw, rice straw, corn straw and wheat straw (the mixing ratio is 4:1:4:1, wherein the sorghum and wheat straw are taken from rural Hebei, the straw is taken from rural Hunan, and the corn straw is taken from the suburb of Daxing, Beijing) , Clostridium thermocellum DSM No.7072 (purchased from German Culture Collection), Clostridium thermocellum DSM No.4150 (purchased from German Culture Collection), Clostridium thermocellum DSM No.572 (purchased from German Culture Collection) Preservation Center) and medium-temperature methanogenic sludge (prepared with reference to the method described in Example 1) to prepare hydrogen and methane by two-stage fermentation, the steps are as follows:

[0100] (1) Crushing and mixing of raw materials

[0101] Collect fiber waste raw materials, use a plant pulverizer to crush them to a particle size below 20mm, weigh a certain amount of solid raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com