Microbial electrolysis cell (MEC) modified biological cathode preparation method and application thereof

A microbial electrolysis cell and biocathode technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of low hydrogen production level of biocathode, low hydrogen production efficiency of biocathode, low microbial catalytic performance, etc., and achieve low cost, The effect of easy operation and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

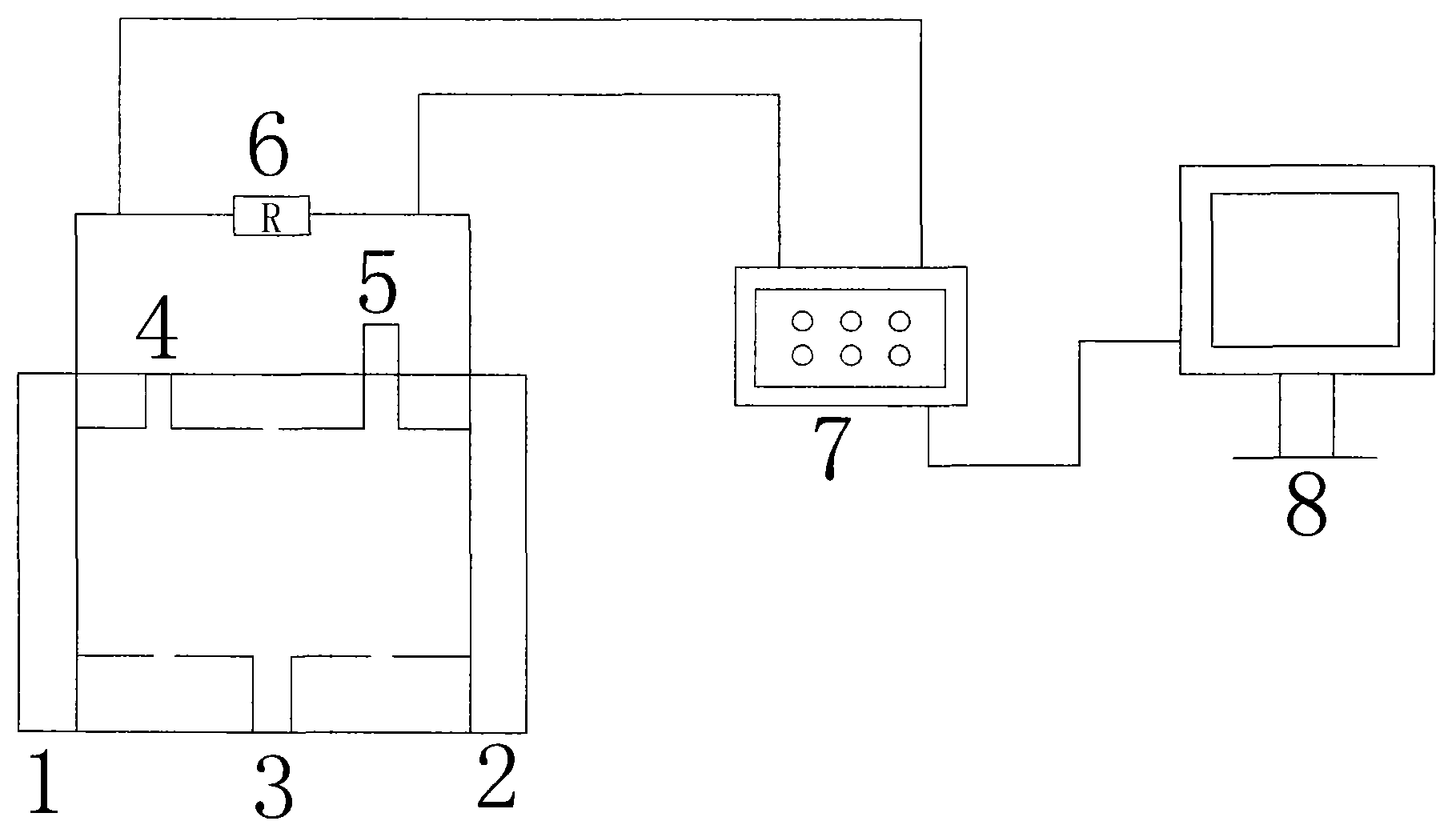

Embodiment 1

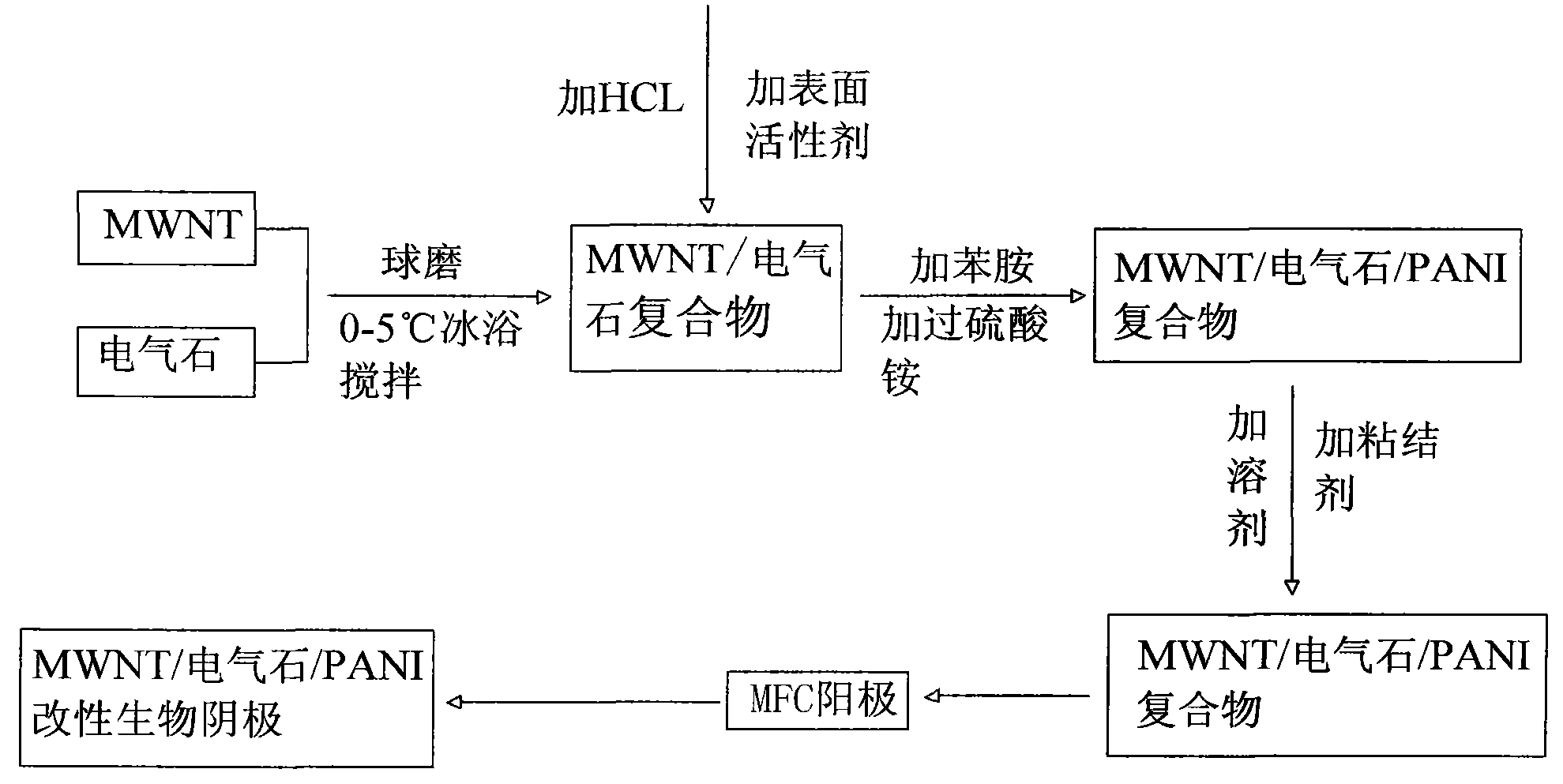

[0039] Step 1: Preparation of MWNT / Tourmaline / PANI Modified Electrode

[0040] Add 2 g of unpurified carbon nanotubes (MWNT) into 100 mL of nitric acid / sulfuric acid mixture (1:3, v / v), stir and react at 80 °C for 12 hours, filter the resulting black liquid, and wash with deionized water until neutral. properties, filtered and dried to obtain purified carbon nanotubes.

[0041] Mix 0.2 g of purified carbon nanotubes with 0.05 g of 8000-mesh black tourmaline powder, and ball mill for 30 min at 400 r / min to obtain a mixture with a mass ratio of carbon nanotubes to tourmaline of 2:1. To the mixture was added 1 mL of the surfactant dodecylbenzenesulfonic acid, 30 mL of concentrated HCl, and 70 mL of HO 2 O, ultrasonically stirred for 3 hours, transferred to 0-5°C ice bath to obtain mixed solution A; 0.6mL of aniline stored in 0-5°C ice bath after vacuum distillation was dissolved in 10mL of 1mol / L HCl solution , added to the above mixed solution A to obtain the mixed solution B;...

Embodiment 2

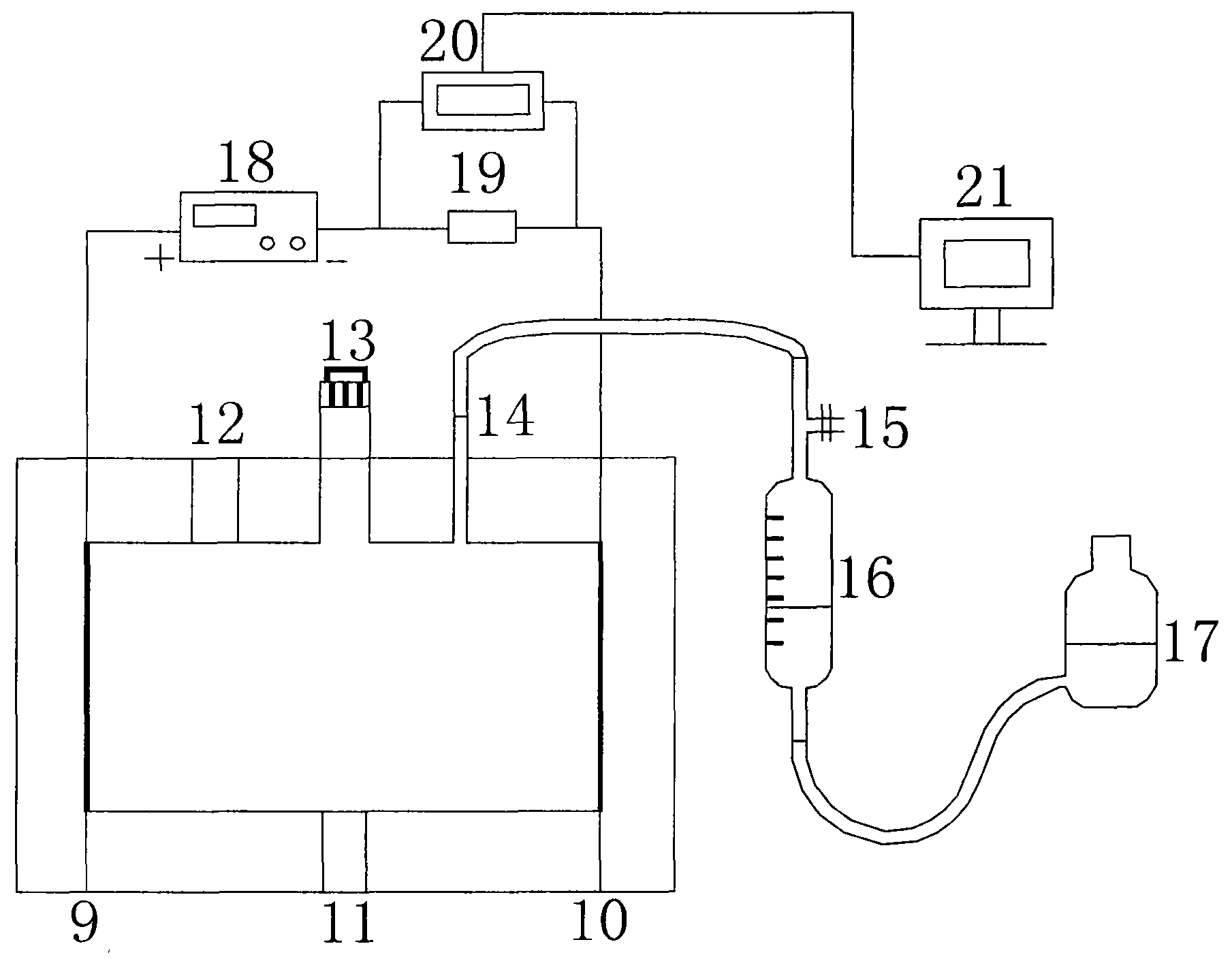

[0051] The difference from Example 1 is that in the first step, 0.2g of purified carbon nanotubes, 0.1g of 8000 mesh black tourmaline powder, 0.6mL of aniline and 1.5g of ammonium persulfate are used to obtain MWNT, tourmaline and PANI in a mass ratio of 24: 12:72 catalytic electrode. After acclimatization and film formation in MFC, it was used as MEC modified biocathode to conduct MEC hydrogen production test. When the applied voltage was 0.9V, the maximum current density was 189Am. -3 , COD removal rate 91.7%, hydrogen yield 1.53m 3 m 3 d -1 . The electrochemical performance test of the modified biocathode was carried out using a three-electrode test system, and the obtained results were as follows: Figure 4 shown.

Embodiment 3

[0053] The difference from Example 1 is that in the first step, 0.6g of purified carbon nanotubes, 0.15g of 8000 mesh black tourmaline powder, 0.2mL of aniline and 0.5g of ammonium persulfate are used to obtain MWNT, tourmaline and PANI in a mass ratio of 24: 6:8 catalytic electrode. After acclimation and film formation in MFC, it was used as a MEC modified biocathode to conduct MEC hydrogen production test. When the applied voltage was 0.9V, the maximum current density was 178Am. -3 , COD removal rate 91.2%, hydrogen yield 1.34m 3 m 3 d -1 . The electrochemical performance test of the modified biocathode was carried out using a three-electrode test system, and the obtained results were as follows: Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com