Method for preparing hydrogen with biology and with utilization of organic waste water step

An organic wastewater, cascade technology, applied in water pollutants, chemical instruments and methods, biological water/sewage treatment, etc., can solve problems such as low conversion rate of biological hydrogen production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

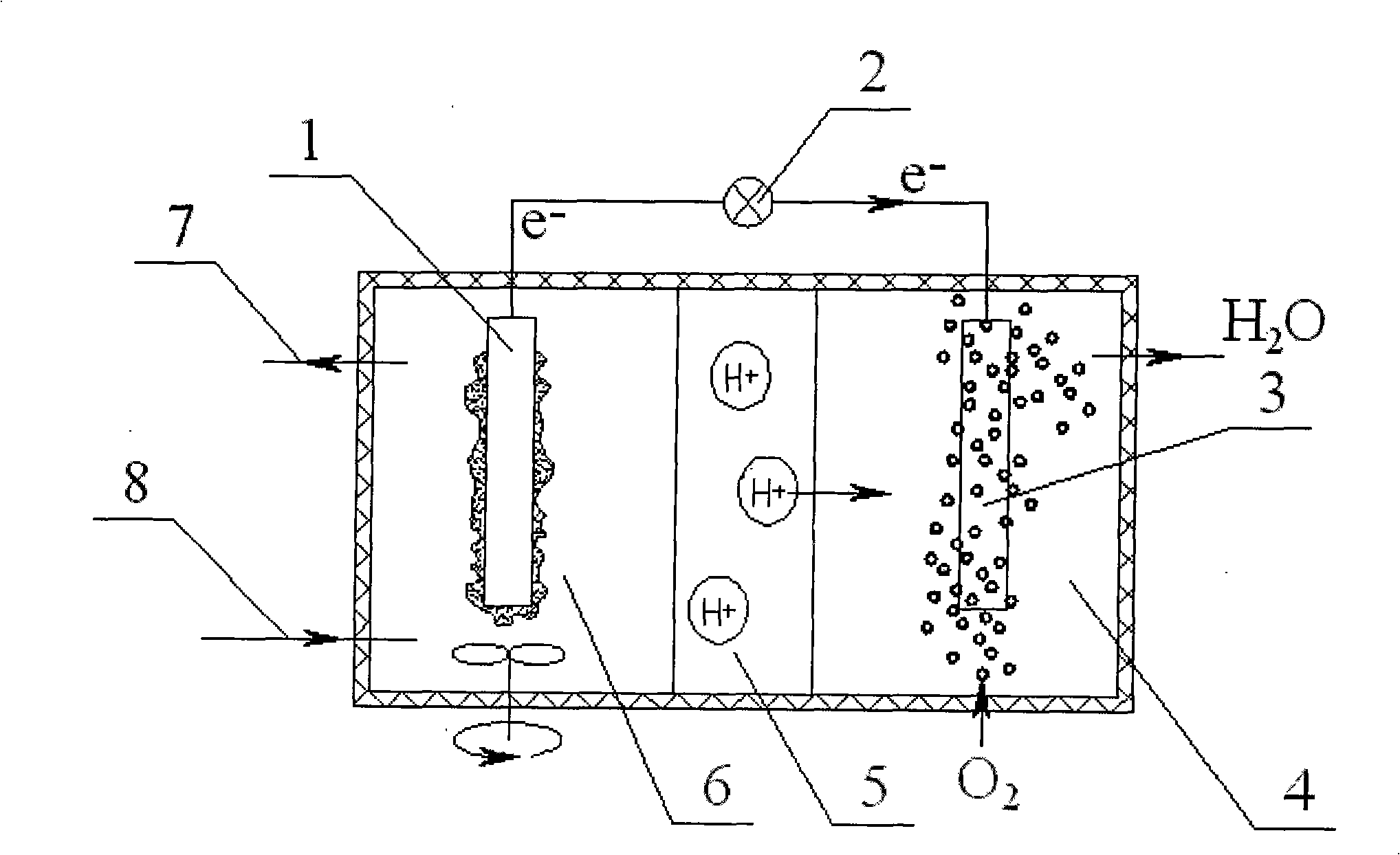

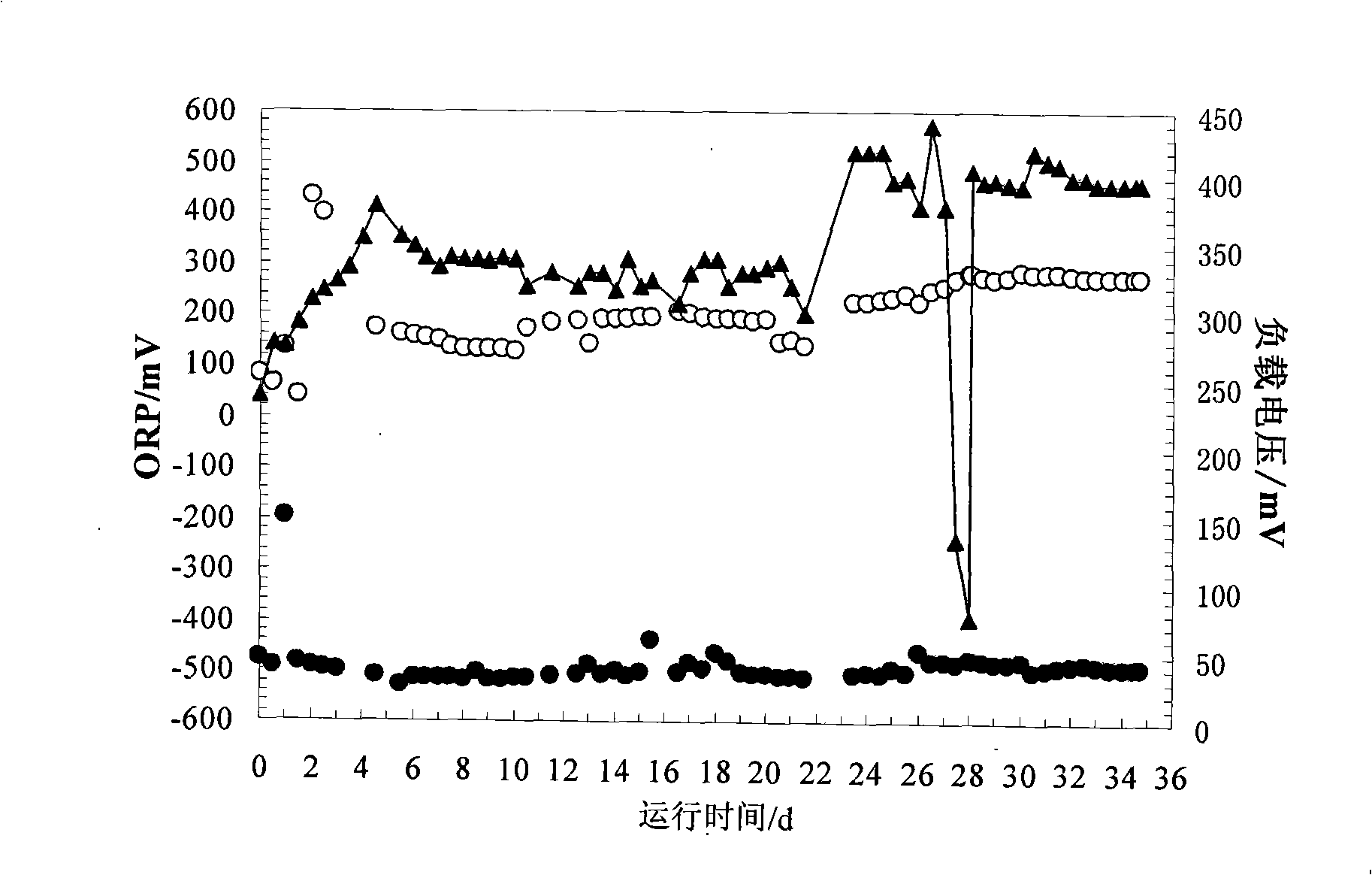

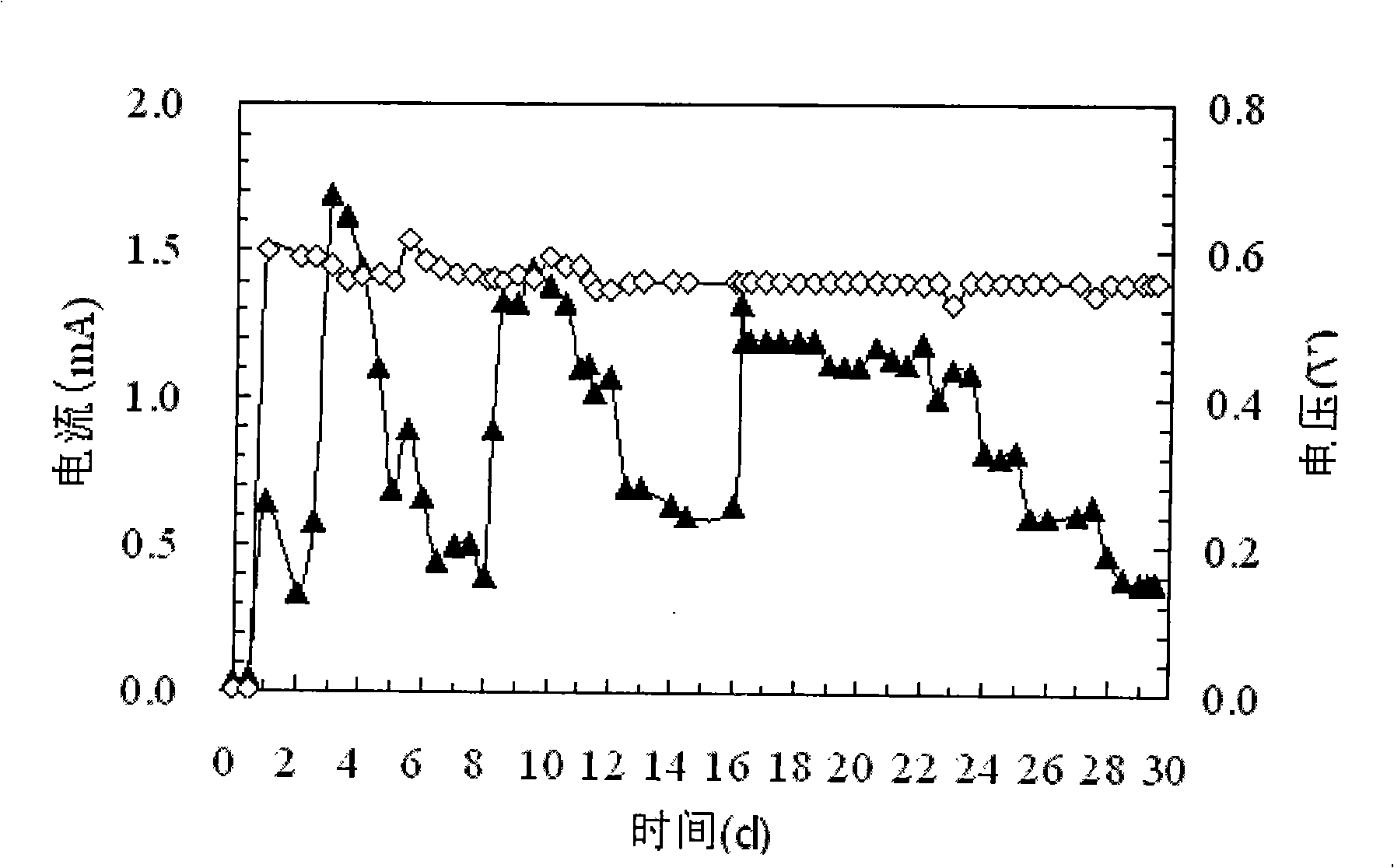

[0014] Specific embodiment one: organic waste water cascade utilization biological hydrogen production is carried out in the double-chamber microbial battery with ion-exchange membrane, is realized by the following steps: 1. Start the reactor: the anode chamber is in the exhausted state during the start-up process. Oxygen state, put anaerobic activated sludge into the anode chamber, the dosage of anaerobic activated sludge accounts for 50% to 60% of the volume of the anode chamber, and then pass the culture solution with a pH value of 6.8 to 7.0 into the anode chamber, and the culture solution The volume ratio of the anaerobic activated sludge to the anaerobic activated sludge is 1:1. At the same time, add phosphate buffer solution accounting for 90% of the volume of the cathode chamber to the cathode chamber, and aerate the air in the cathode chamber in the first 28 to 35 days of starting. The aeration rate is 0.3 ~0.6m 3 / min, when the battery voltage is lower than 50mV, com...

specific Embodiment approach 2

[0017] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the nutrient solution of step one is made of 0.31g ammonium chloride, 0.13mg potassium chloride, 5.618g sodium dihydrogen phosphate dihydrate, 6.155g phosphoric acid dihydrate Disodium hydrogen, 2g sodium acetate trihydrate, 1L deionized water and 2ml trace element solution. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0018] Specific embodiment three: the difference between this embodiment and specific embodiment two is: every liter of trace element liquid is made of 600mg calcium chloride, 400mg magnesium chloride, 80mg ferrous chloride, 400mg cobalt chloride, cupric chloride, 100mg chloride Manganese, 10mg zinc chloride, 10mg sodium selenate, 15mg sodium tungstate, 20mg nickel chloride, 100mg disodium ethylenediaminetetraacetic acid (disodium EDTA), 10mg ammonium molybdate and the rest of water. Others are the same as in the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com