Aluminum-rare earth micro nano composite hydrogen manufacturing material

A micro-nano, rare earth technology, applied in the production of hydrogen, etc., can solve the problems of complex synthesis process of hydrogen production materials, incomplete reaction of hydrogen production materials, high cost of hydrogen production, etc., to achieve wide practicability, stable properties, and low product cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The preparation steps of the Al-Ce micro-nano composite hydrogen production material in this example are as follows:

[0047] a. Weigh 1.7403g of aluminum powder and put it into a 50ml stainless steel ball mill jar;

[0048] b. Add 1.0ml of ethanol to the stainless steel tank, add 0.2603g of cerium powder into the stainless steel tank under argon protection, and seal the tank mouth with a lid;

[0049] c. Put the stainless steel tank on the planetary ball mill, the ball-to-material ratio is 60:1, the rotating speed is 500 rpm, and the ball mill is 8 hours to prepare Al-Ce micro-nano composite hydrogen production material 1 (Al87wt%-Ce13wt%) .

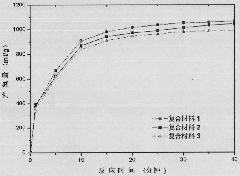

[0050] d. Take 0.1045g of Al-Ce micro-nano composite hydrogen production material 1 and react with 70ml of pure water at 70°C; measure the volume of hydrogen gas produced, and draw the hydrogen production curve according to the volume time ( figure 1 ).

[0051]e. the solution after the reaction is centrifuged, and after dryin...

Embodiment 2

[0053] The preparation process and steps of the Al-La micro-nano composite hydrogen production material in this example are as follows:

[0054] a. Weigh 1.7398g of aluminum powder and put it into a 50ml stainless steel ball mill jar;

[0055] b. Add 1.0ml of ethanol to the stainless steel tank, then add 0.2601g of lanthanum powder to the stainless steel tank under argon protection, and seal the tank mouth with a lid;

[0056] c. Put the stainless steel tank on the planetary ball mill at a ball-to-material ratio of 60:1, a rotating speed of 500 rpm, and ball milling for 8 hours to obtain Al-La micro-nano composite hydrogen production material 2 (Al87wt%-La13wt%) .

[0057] d. Take 0.1045g of Al-La micro-nano composite hydrogen production material 2 to react with 70ml of pure water at 70°C, measure the volume of hydrogen gas produced, and draw the hydrogen production curve according to the volume and time ( figure 1 ).

Embodiment 3

[0059] The preparation steps of the Al-Ce micro-nano composite hydrogen production material in this example are as follows:

[0060] a. Weigh 1.7399g of aluminum powder and put it into a 50ml stainless steel ball mill jar;

[0061] b. Add 1.0ml of ethanol to the stainless steel tank, add 0.2600g of yttrium powder into the stainless steel tank under argon protection, and seal the tank mouth with a lid;

[0062] c. Put the stainless steel tank on the planetary ball mill, the ball-to-material ratio is 60:1, the rotating speed is 500 rpm, and the ball mill is 8 hours to prepare Al-Y micro-nano composite hydrogen production material 3 (Al87wt%-Y13wt%) .

[0063] d. Take 0.1045g of Al-Y micro-nano composite hydrogen production material 3 and react with 70ml pure water at 70°C; measure the volume of hydrogen gas produced, and draw the hydrogen production curve according to the volume and time ( figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com