TiO2/BiVO4 photo-anode material and preparation method thereof

A photoanode, nanoparticle technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problem of less research, and achieve the effect of increasing specific surface area, improving the performance of photo-electrolyzed water, and reducing the probability of recombination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

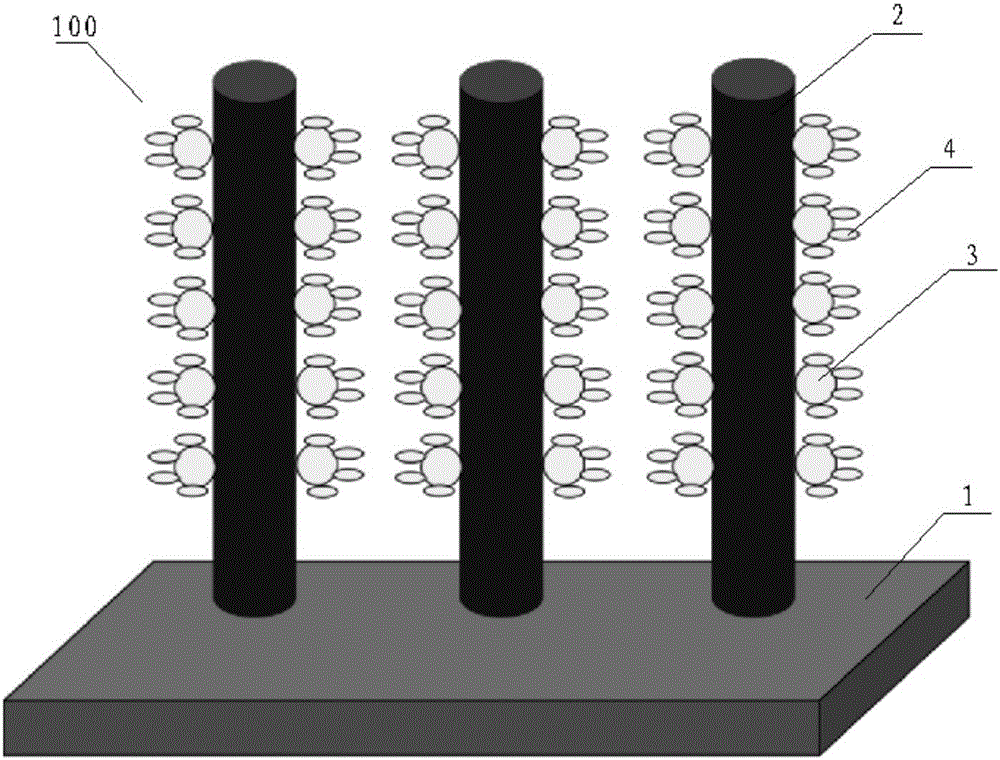

[0020] On the other hand, the present invention provides the TiO 2 / BiVO 4 The preparation method of photoanode material, it comprises the following steps:

[0021] (1) Prepare 6ml-10ml of deionized water, 6ml-10ml of 36.5-38wt% concentrated hydrochloric acid and 0.18ml-0.23ml of 98wt% tetra-normal titanate solution, and immerse the substrate 1 in the mixed solution at 150°C-180°C Reaction for 4h-10h, and finally annealing in air at 450-550°C for 1h-2h to obtain TiO 2 nanorod arrays;

[0022] (2) Configure soluble Bi salt and soluble V 4+ The mixed solution of salt, adjust mixed solution pH to 4.7, with the TiO that step (1) obtains 2 The nanorod array is the working electrode, set the reference electrode and the counter electrode, and deposit BiVO under the condition of 2.1V-2.3V voltage and 1.5C-4C power condition 4 The nanoparticle layer is annealed at 450°C-550°C after deposition to obtain the TiO 2 / BiVO 4 Photoanode material.

[0023] Specifically, the substrate ...

Embodiment 1

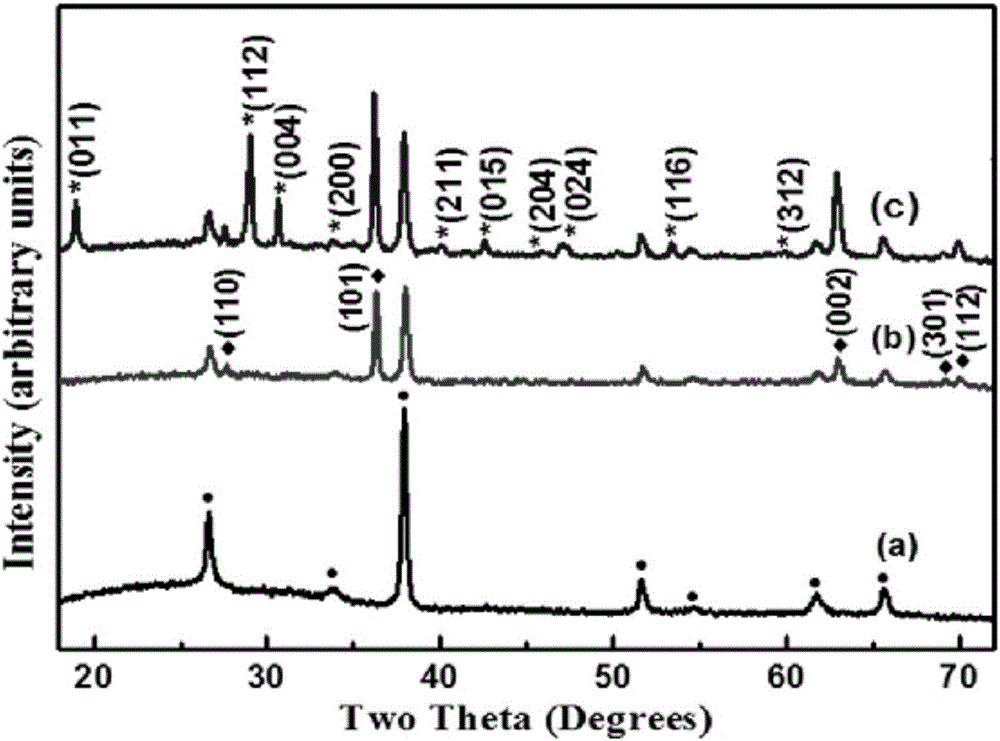

[0035] Clean the surface of the FTO conductive glass first, then ultrasonically in deionized water, acetone, alcohol, and deionized water for 20 minutes, then dry it with a hair dryer, and soak it in alcohol for sealed storage. Carry out XRD analysis to FTO conductive glass, obtain as follows figure 2 (a) The curve shown.

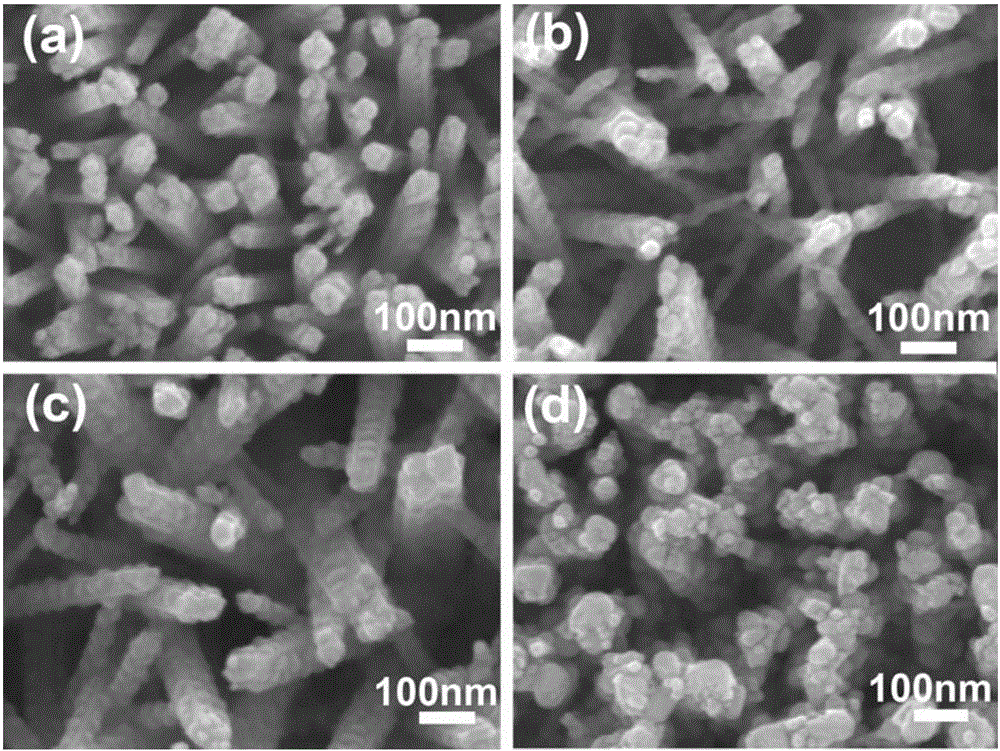

[0036] (1) Prepare 8ml of deionized water, 8ml of 36.5-38wt% concentrated hydrochloric acid and 0.2ml of 98wt% tetra-n-decyl titanate solution, lean the FTO conductive glass at an angle of 45° and immerse it in the mixed solution. The reaction volume is 25ml polytetrafluoroethylene jar, then placed in an oven at 150°C for 10h, and finally annealed in air at 500°C for 2h to obtain TiO 2 nanorod arrays. To get TiO 2 Nanorod arrays were analyzed by XRD, as shown in figure 2 (b) The curve shown.

[0037] (2) Prepare 35mmol / l VOSO with pH4 solution, followed by 10mmol / l Bi(NO 3 ) 3 solution dissolved in VOSO 4 solution, and then use concentrated nitric...

Embodiment 2

[0040] Clean the surface of the FTO conductive glass first, then ultrasonically in deionized water, acetone, alcohol, and deionized water for 20 minutes, then dry it with a hair dryer, and soak it in alcohol for sealed storage.

[0041] (1) Prepare 8ml of deionized water, 8ml of 36.5-38wt% concentrated hydrochloric acid and 0.2ml of 98wt% tetra-n-decyl titanate solution, lean the FTO conductive glass at an angle of 45° and immerse it in the mixed solution. The reaction volume is 25ml polytetrafluoroethylene jar, then placed in an oven at 150°C for 10h, and finally annealed in air at 500°C for 2h to obtain TiO 2 nanorod arrays.

[0042] (2) Prepare 35mmol / l VOSO with pH4 solution, followed by 10mmol / l Bi(NO 3 ) 3 solution dissolved in VOSO 4 solution, and then use concentrated nitric acid to adjust the pH of the above mixed solution to below 0.5, and then use 2mol / l CH 3 The pH of the solution was adjusted to 5.1 with COONa solution, and finally the pH of the mixed solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com