Method for treating easily-degradable organic waste in two-phase hydrogen-production methane-production coupling reaction

A technology of organic waste and coupled reaction, applied in the direction of waste fuel, fermentation, etc., can solve the problems of no patent report, difficulty in achieving balance of production capacity, low calorific value, etc., to improve degradability and anaerobic digestion potential, The effect of promoting hydrolysis and acidification efficiency and reducing the content of CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

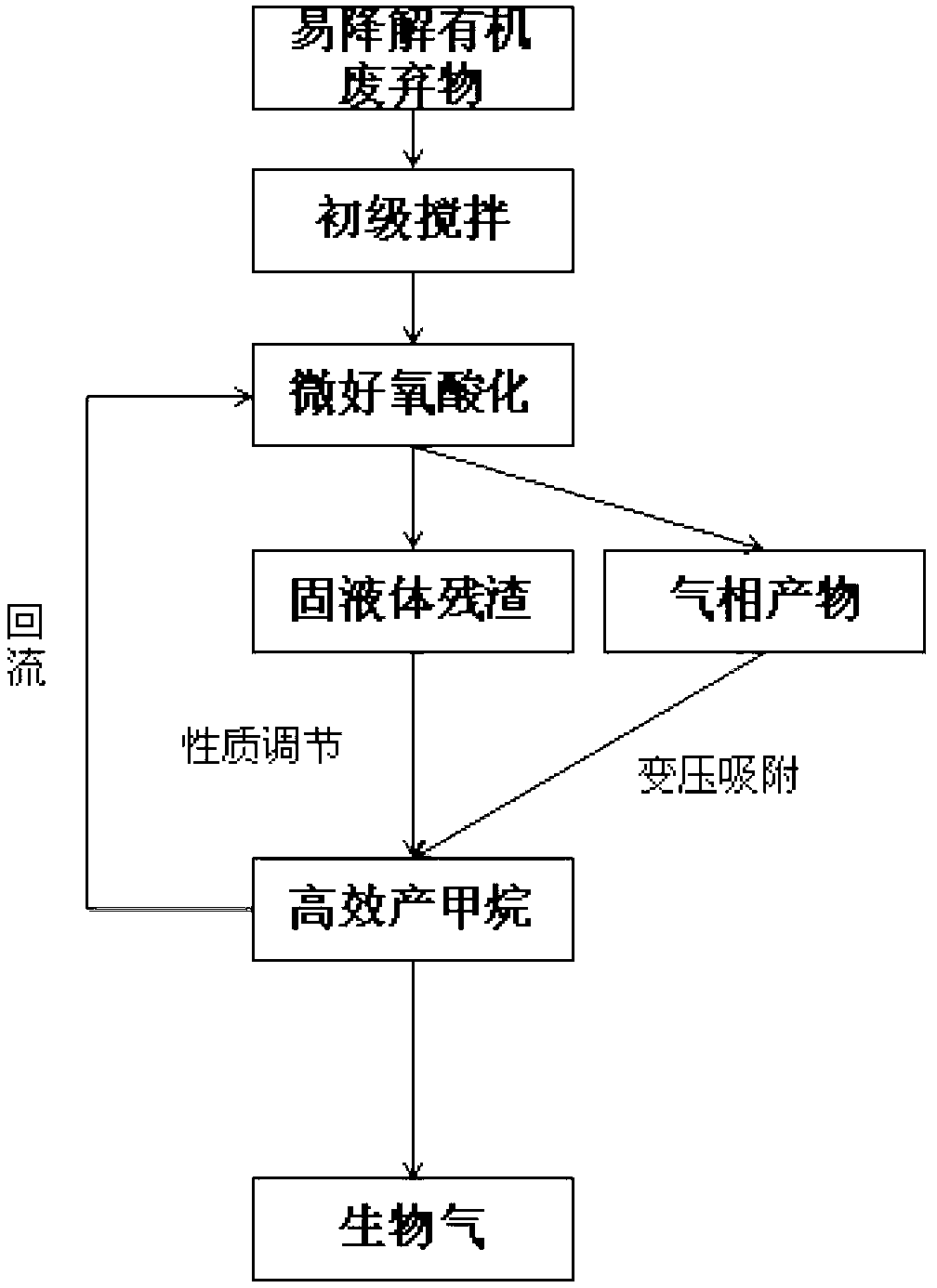

Image

Examples

Embodiment Construction

[0012] The present invention will be further described in detail below in conjunction with specific embodiments.

[0013] The system includes a raw material stirring system, a 5L hydrolysis acidification reactor, a 2L methanation reactor, and a pressure swing adsorption decarbonization device. Add inoculated sludge with a concentration of 25000mg / L and pass in a certain amount of oxygen to maintain a dissolved oxygen concentration of 0.3mg / L for microaerobic pretreatment and acidification. Add NaOH to the acidified liquid-solid phase product to adjust the pH to 7.0. Enter the high-efficiency methane production process through continuous feeding, and at the same time pass the acidified gas into the decarburization unit for purification, and the purified H 2 After entering the methanation reactor with CO 2 A reduction reaction occurs to produce methane. At the same time, the constant flow peristaltic pump is used to realize the recirculation of the effluent of the methanation react...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com