Carbon nano tube supported nickel catalyst as well as preparation method and application thereof

A carbon nanotube and catalyst technology, applied in the field of carbon nanotube-supported nickel catalyst and its preparation, can solve the problems of rapid catalyst deactivation, short service life, high reforming temperature, etc., and achieve excellent adsorption-desorption performance, high mechanical strength, effect of reducing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Example 1. Preparation of carbon nanotube-supported nickel catalyst by urea hydrolysis uniform precipitation method

[0038] 1. Using urea hydrolysis uniform precipitation method to prepare carbon nanotube-supported nickel catalyst I

[0039] (1) Carbon nanotube purification and surface modification: 30g carbon nanotubes are placed in a mixture of 500ml of concentrated nitric acid (65%-68%) and concentrated sulfuric acid (98%) with a volume ratio of 3:1. Continue mechanical stirring at a speed of 150rpm, and keep the temperature at 90℃, and condense and reflux for 6h; the treated carbon nanotubes are washed with deionized water and filtered 3 times until the pH of the filtrate reaches 7 to be cleaned; The washed carbon nanotubes are dried at 110°C for 10 hours, and ground for use;

[0040] (2) Weigh 8.74g nickel nitrate (molecular formula: Ni(NO 3 ) 2 ·6H 2 O, purity: analytically pure AR) dissolved in 500ml of distilled water (the mass ratio of nickel nitrate to distilled ...

Embodiment 2

[0068] Example 2: Preparation of Ni-γ-Al by urea hydrolysis uniform precipitation method 2 O 3 catalyst

[0069] (1) Weigh 8.74g nickel nitrate (molecular formula: Ni(NO 3 ) 2 ·6H 2 O, purity: analytically pure AR) dissolved in 500ml distilled water, while adding 10g γ-Al 2 O 3 , After stirring, vibrate ultrasonically for 10 minutes, and use concentrated nitric acid to adjust the PH value of the mixed solution to between 1-2, then add 5.4g of urea and keep stirring continuously;

[0070] (2) Heat the above-mentioned mixed solution and keep it at about 90°C, while condensing and refluxing for 24 hours, until the pH value reaches about 6-7 and the reaction is over;

[0071] (3) Suction filtration of the above-mentioned hydrolyzed precipitate and washing with deionized water; placing the washed precipitate in a drying box and drying at 120°C for 10 hours;

[0072] (4) Slowly heat the dried precipitate to 500°C at a temperature increase rate of 1°C / min, and roast it in an air atmosphe...

Embodiment 3

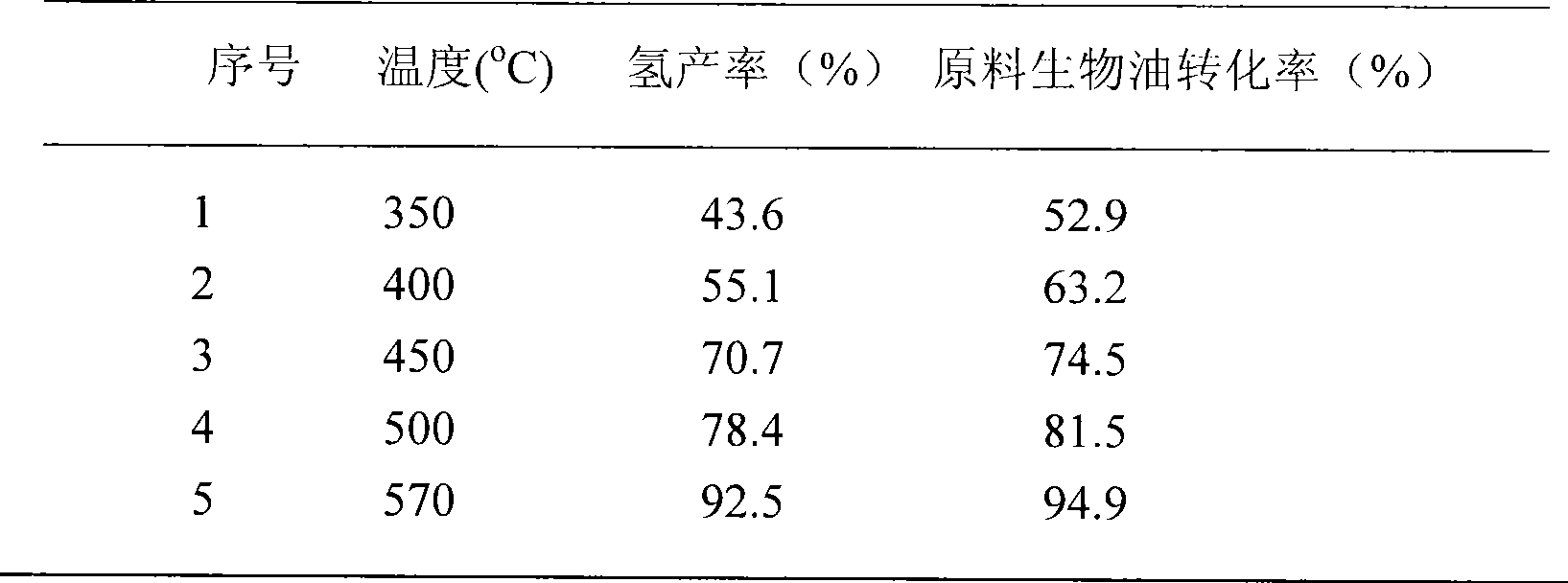

[0074] Example 3. Application of carbon nanotube-supported nickel catalyst in hydrogen production from bio-oil

[0075] The evaluation of catalytic activity was carried out on a quartz fixed-bed flow reactor-gas chromatography (GC) combined system.

[0076] The reaction device is a quartz fixed-bed flow reactor, which includes a cylindrical quartz tube reactor (inner diameter: Φ2.5mm, length: 40cm) with an external heating electric furnace and reactants (bio-oil and water) connected at both ends Steam) inlet pipeline and reaction tail gas output pipeline; the bio-oil storage tank and steam generator are respectively connected to the inlet pipeline, and are respectively provided with control valves and reactant flow controllers. The outer wall of the inlet pipeline is provided with a Hot external heating device; connected to the output pipeline, including steam condenser, CO 2 The tail gas collection and purification system including the chemical absorber and the dryer; the reactio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com