Device and method for catalytic hydrogen preparation from methane and carbon dioxide

A carbon dioxide and hydrogen production device technology, applied in chemical instruments and methods, hydrogen, inorganic chemistry, etc., can solve the problems of CO2 not being reused, exhaust gas is difficult to deal with, and membrane damage is large, so as to achieve low operating costs and increase productivity , Improve the effect of hydrogen production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

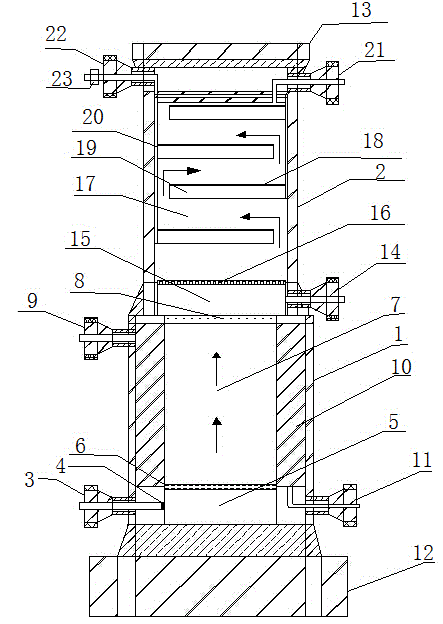

[0039] First illustrate the structure of methane carbon dioxide catalytic hydrogen production device of the present invention:

[0040] Such as figure 1 As shown, it mainly includes two parts, the upper water gas conversion and hydrogen membrane separation section 2 and the lower synthesis gas generation section 1, the bottom of the synthesis gas generation section 1 is provided with a first flange sealing plate 12, and the water gas conversion and hydrogen membrane separation The top of section 2 is provided with a second flange sealing plate 13, and the synthesis gas generation section 1 and the water gas conversion and hydrogen membrane separation section 2 are separated by a gas check valve 8, which is fixed on the synthesis gas generation section 1 Top; the lower part of the synthesis gas section is provided with methane and carbon dioxide gas inlets 3, and the methane and carbon dioxide gas inlets 3 are connected to the first gas mixing chamber 5, and the upper end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com