Sodium borohydride hydrogen making reaction device and method thereof

A sodium borohydride and reaction device technology, applied in the field of sodium borohydride hydrogen production reaction device, can solve the problems of being unsuitable for portable low-power fuel cell systems, unsafe hydrogen storage and transportation, and bulky energy storage systems. Convenience, high energy efficiency, and high hydrogen purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

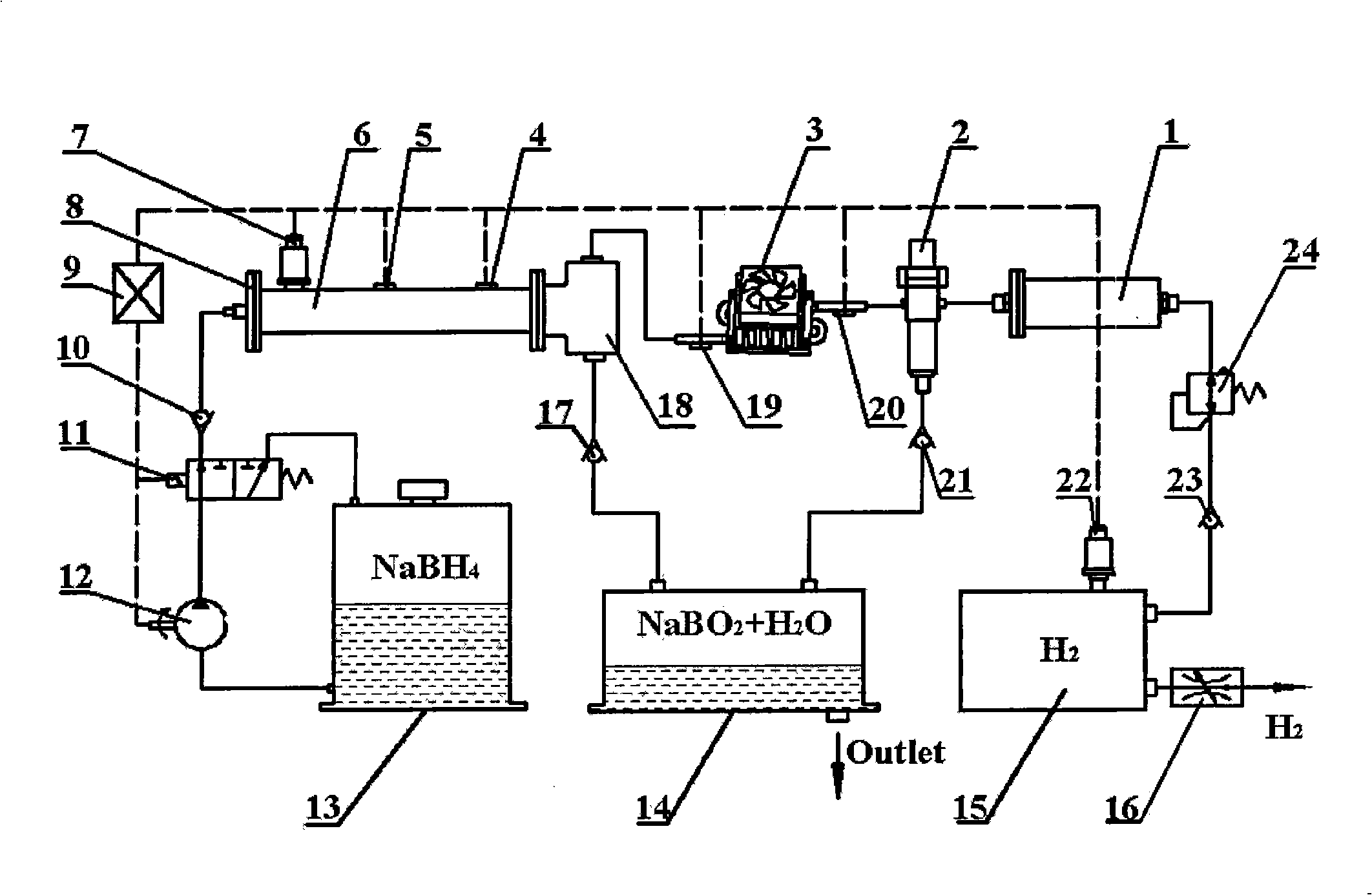

[0034] Embodiment 1: According to figure 1 The shown sodium borohydride hydrogen production device adopts a sodium borohydride solution with a concentration of 10%, the flow rate of the low-power hydraulic pump 12 is 30ml / min, and the initial setting on-off time ratio of the high-speed solenoid valve 11 is 1:6. The outlet pressure set by the decompression valve 24 is 0.1MPa. The pressure sensor 7 collects the pressure signal in the reaction chamber and feeds the signal back to the control board 9, and compares it with the pressure 0.1-0.2Mpa set by the user to adjust the high-speed solenoid valve. on-off time ratio. The hydrogen sensor 4 collects the hydrogen concentration signal outside the reaction chamber and feeds the signal back to the control board. It is found that the concentration is not greater than the set safety value of 4%, and the system works normally. Thermistor 2 19 and thermistor 3 20 respectively collect the hydrogen temperature signals at the inlet and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com