Integral catalyst applied to biological oil reforming hydrogen production, preparation and application thereof

A reforming hydrogen production, integrated technology, applied in catalyst activation/preparation, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem that cannot meet the requirements of large-scale production of industrial catalysts , limit industrial application, limited reserves and other problems, to achieve the effect of improving bio-oil conversion rate, strong anti-carbon deposition ability, and low mass transfer resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] Two, the preparation of catalyst:

[0032] 3) The selected alkali metal additives and noble metal additives are formulated into corresponding soluble salt solution C.

[0033] 4) Mix the aqueous solution of the soluble nickel-based salt with C according to the composition ratio of the aforementioned catalyst, and after stirring evenly, immerse the prepared catalyst carrier B in the mixed solution, ultrasonically vibrate, age for 24 hours, and dry at 120°C for 8~ After 12 hours, it is calcined at 500-800°C for 6-10 hours, and then reduced in a hydrogen atmosphere at 400-600°C for 2-4 hours to obtain a monolithic catalyst for hydrogen production by steam reforming of bio-oil.

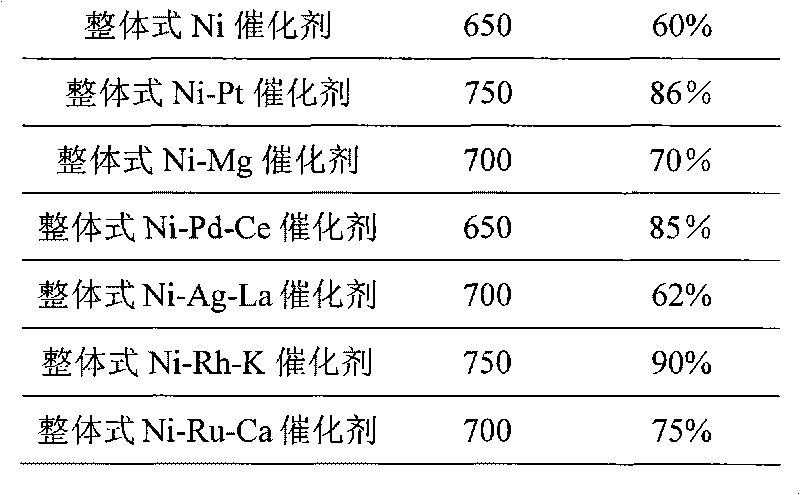

Embodiment 1

[0034] The preparation of embodiment 1 monolithic Ni catalyst

[0035] The commercially available porous ceramic carrier has a specification of φ15×30mm, a pore density of 300 pores / square inch, and a specific surface area of 1.0m 2 / g, in a muffle furnace at 600 ° C for 6 hours and then naturally cooled to room temperature for later use. γ-Al2O3 with an average particle size of 100nm, deionized water and polyethylene glycol were mixed at a solid content of 30%, mixed on a ball mill to prepare a suspension, and ground for 40 hours. Then the prepared porous ceramic support was impregnated several times, so that its surface could be evenly coated with a layer of 5% γ-Al 2 o 3 , and then put it in an oven at 120° C., dry it for 8 hours, and then bake it at 600° C. for 6 hours to prepare a monolithic catalyst carrier for bio-oil reforming hydrogen production. Dissolve nickel nitrate with a nickel content of 20% of the mass of the catalyst in deionized water, impregnate the mon...

Embodiment 2

[0036] Example 2 Preparation of monolithic Ni-Pt catalyst

[0037] The commercially available ceramic foam carrier has a specification of φ15×20mm, a pore density of 350 pores / square inch, and a specific surface area of 5.0m 2 / g, in a muffle furnace at 600 ° C for 6 hours and then naturally cooled to room temperature for later use. γ-Al with an average particle size of 600nm 2 o 3 , deionized water and polyethylene glycol were mixed according to a solid content of 15%, mixed on a ball mill to prepare a suspension, and ground for 40 hours. Then the prepared foamed ceramic carrier was impregnated several times, so that its surface could be evenly coated with a layer of 3% γ-Al 2 o 3 , and then put it in an oven at 120° C., dry it for 8 hours, and then bake it at 600° C. for 6 hours to prepare a monolithic catalyst carrier for bio-oil reforming hydrogen production. Dissolving nickel nitrate with a Ni content of 5% of the catalyst mass and platinum nitrate with a Pt conten...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com