Cobalt-based MOFs material, and preparation method and application thereof

A cobalt-based, hexahydrate cobalt nitrate technology, applied in the field of catalytic chemistry, can solve the problems of limited reserves and expensive precious metal catalysts, and achieve the effects of regular product phase structure, excellent catalytic efficiency, and simple experimental operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0025] Step 1) Weigh 0.75g of cobalt nitrate hexahydrate, dissolve it in 9 ml of absolute ethanol, then weigh 0.428 g of terephthalic acid and dissolve it in 36 ml of N,N-dimethylformamide, and magnetically stir until a clear solution , mixed in a water bath at 40 °C, and ultrasonically treated for 15 min;

[0026] Step 2) Put the ultrasonic solution in step (1) into a reaction kettle with a Teflon substrate, and place it in a 100°C oven for 24 hours. After the reaction, control the oven to cool down to room temperature at 5°C / min After standing for 2 days, the filtered product was washed three times with N,N-dimethylformamide and absolute ethanol, and dried in an oven at 80 °C for 12 h to obtain cobalt-based MOFs materials.

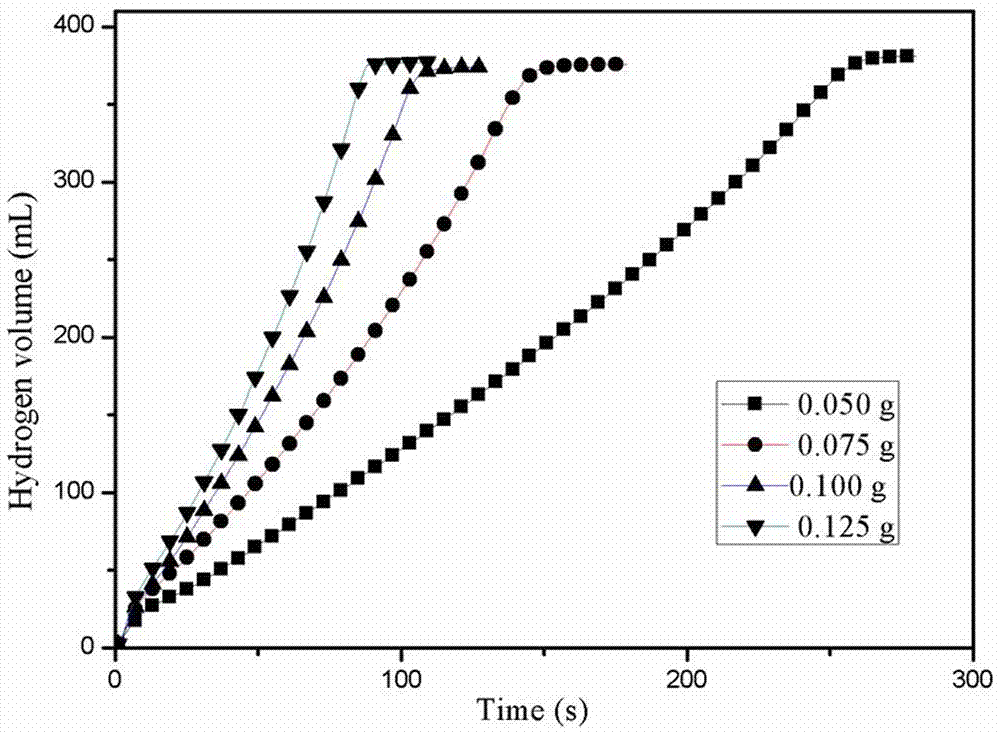

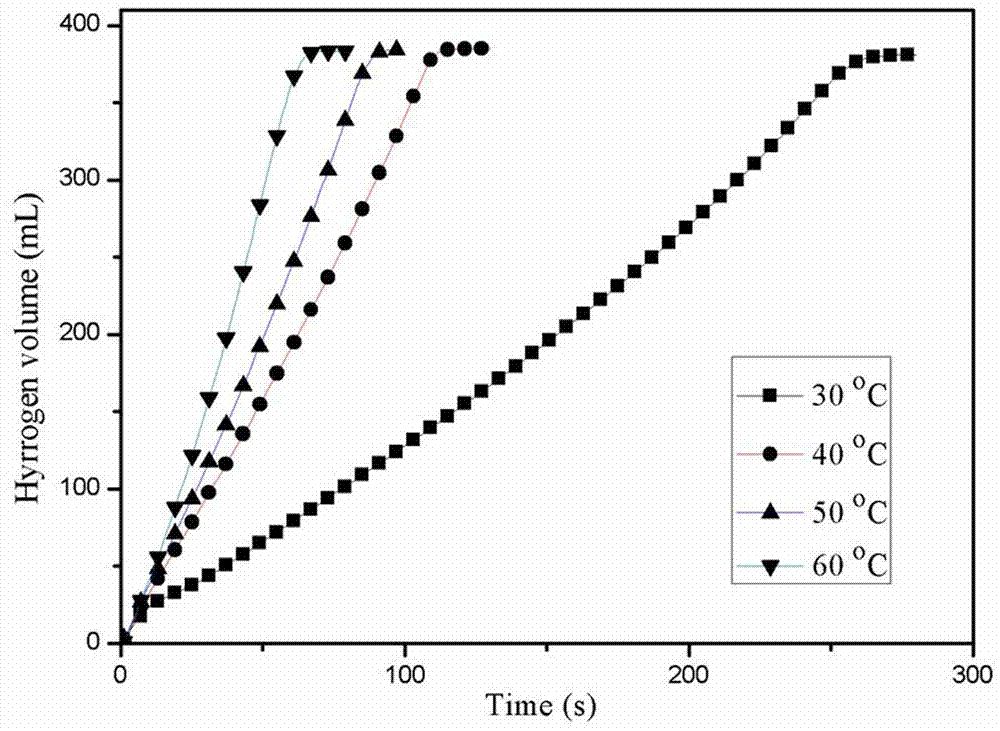

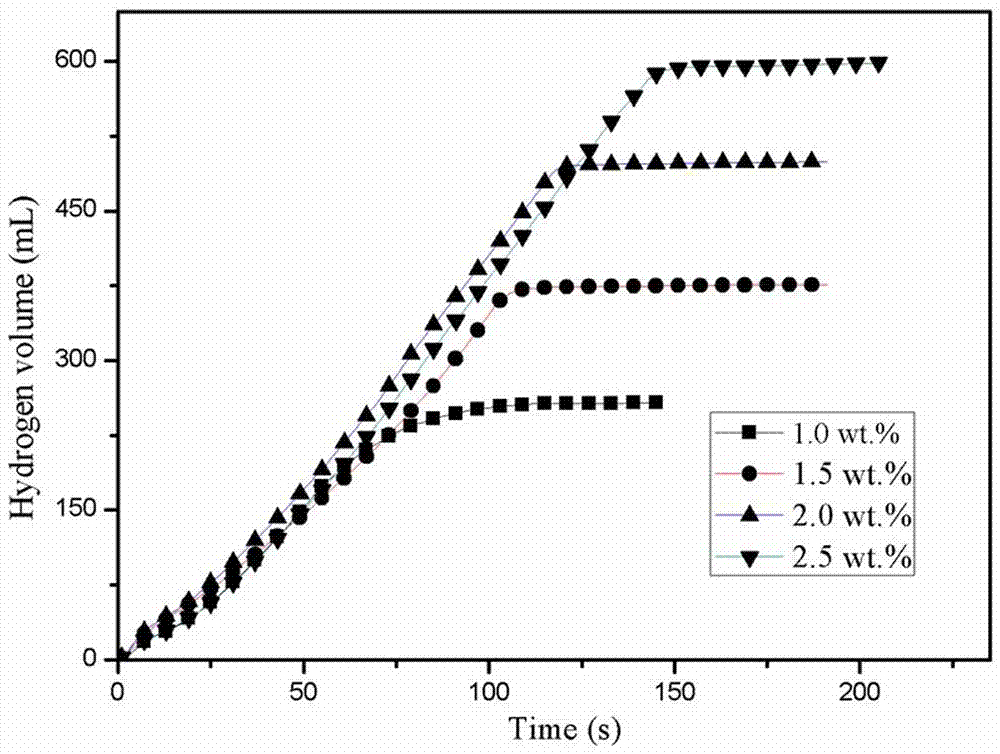

[0027] In the cobalt-based MOFs material catalytic performance test in the embodiment, the hydrogen desorption performance is calculated by the drainage method. The experimental test results show that the catalytic performance of catalysts with different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com