Method for promoting cracking of household garbage by using water vapor

A domestic garbage and water vapor technology, applied in the manufacture of combustible gas, solid waste removal, petroleum industry, etc., can solve the problems of reducing cracking efficiency, heat loss, etc., and achieve the effect of high hydrogen production rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

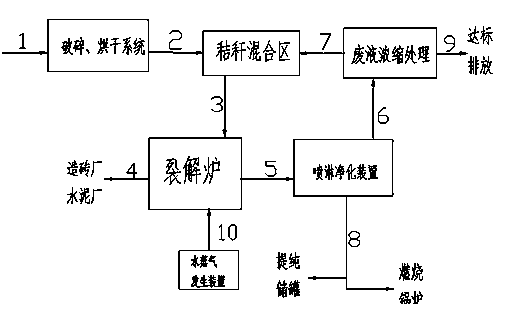

[0008] The present invention will be further described below in conjunction with accompanying drawing.

[0009] In the figure: domestic garbage 1, crushed and dried garbage 2, straw, garbage mixture 3, residue 4, gas-liquid mixture 5, waste liquid 6, concentrated waste liquid 7, gas 8, clean water 9, water vapor 10.

[0010] (1) Household waste is crushed and dried and mixed with straw, and the mixed material is sent to the cracking furnace for cracking;

[0011] (2) Spray water vapor into the furnace during the cracking process;

[0012] (3) The gas-liquid mixture produced during the cracking process passes through the spray purification device.

[0013]

[0014] 1. Domestic waste is recycled and crushed and dried. After drying and crushing, it is mixed with straw. The moisture content of the mixed material is reduced to 7%~10%, and the particle size is 1~5mm. It is sent into the cracking furnace through the material conveying system for cracking treatment. During the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com