Pre-treatment method used for increasing residual activated sludge anaerobic fermentation hydrogen production efficiency

A technology of sludge anaerobic fermentation and residual activity, applied in biological sludge treatment, water/sludge/sewage treatment, fermentation, etc. Unfavorable biological treatment and other problems, to achieve the effect of efficient and stable hydrogen production process, realization of resource utilization, and short pretreatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

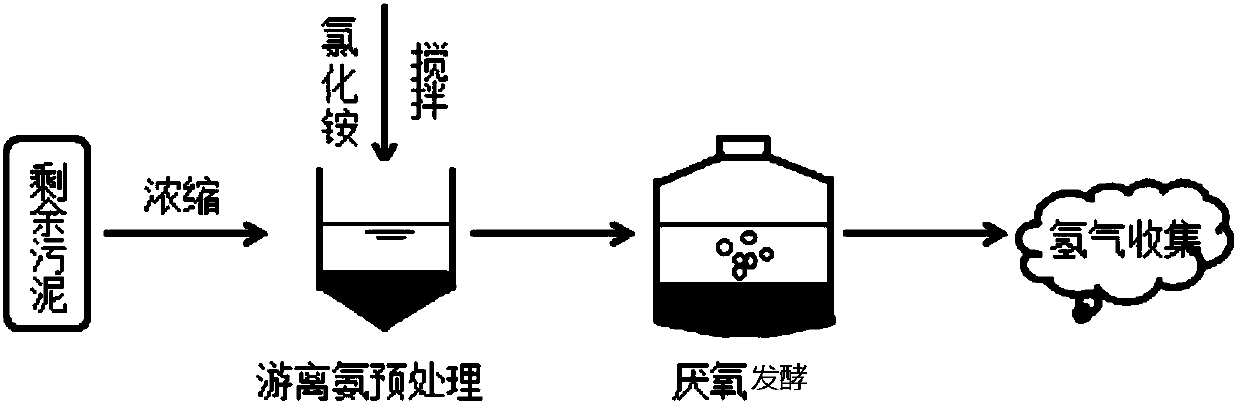

Method used

Image

Examples

Embodiment 1

[0025] (1) Preparation of fermentation substrate: take the remaining sludge (water content 98%, pH=6.86) from the sewage treatment plant and place it in a refrigerator at 4° C. for natural precipitation for 24 hours. Remove the supernatant and carry out concentration treatment so that the VSS is in the range of 13-18g / L to obtain the fermentation substrate.

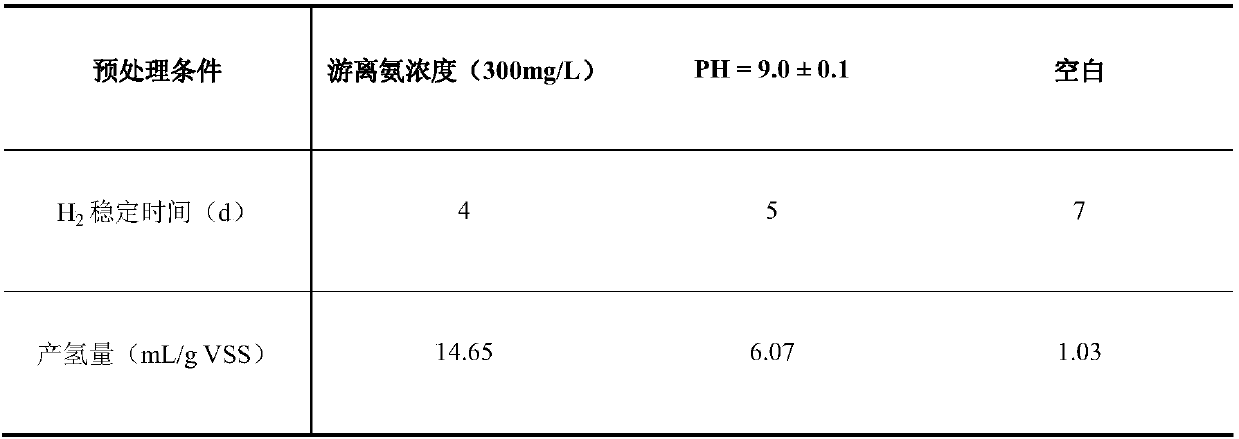

[0026] (2) Pretreatment: Take 500mL of the fermentation substrate obtained in step (1) in an anaerobic reactor, add 0.8173g of ammonium chloride to it, during which the temperature is controlled at 37±0.5°C, and the pH is constantly adjusted to 9.0± 0.1, make the concentration of free ammonia in the pretreatment stage 300mg / L, and maintain it for 12h.

[0027] (3) Anaerobic fermentation: After 12 hours, fill the above-mentioned anaerobic reactor with nitrogen for 1.5 minutes to drive out oxygen, seal it and put it in a constant temperature shaking incubator for anaerobic fermentation to produce hydrogen. It is 130rpm / min...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com