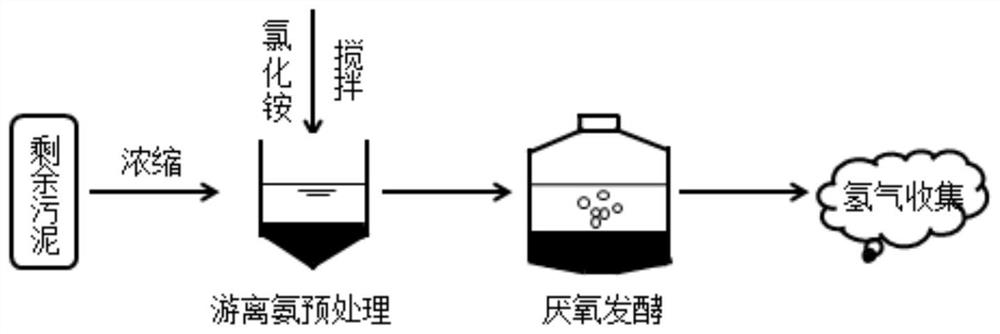

A pretreatment method for improving the hydrogen production efficiency of anaerobic fermentation of excess activated sludge

A technology of sludge anaerobic fermentation and residual activity, applied in biological sludge treatment, water/sludge/sewage treatment, fermentation, etc. Unfavorable biological treatment and other problems, to achieve the effect of efficient and stable hydrogen production process, realization of resource utilization, and short pretreatment time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Preparation of fermented product group: Take sewage treatment plant sludge (water content 98%, pH = 6.86) is placed in a laboratory refrigerator 4 ℃ in natural sedimentation 24h. The supernatant was removed and concentrated processing, the VSS is 13-18g / L range to obtain a fermented product group.

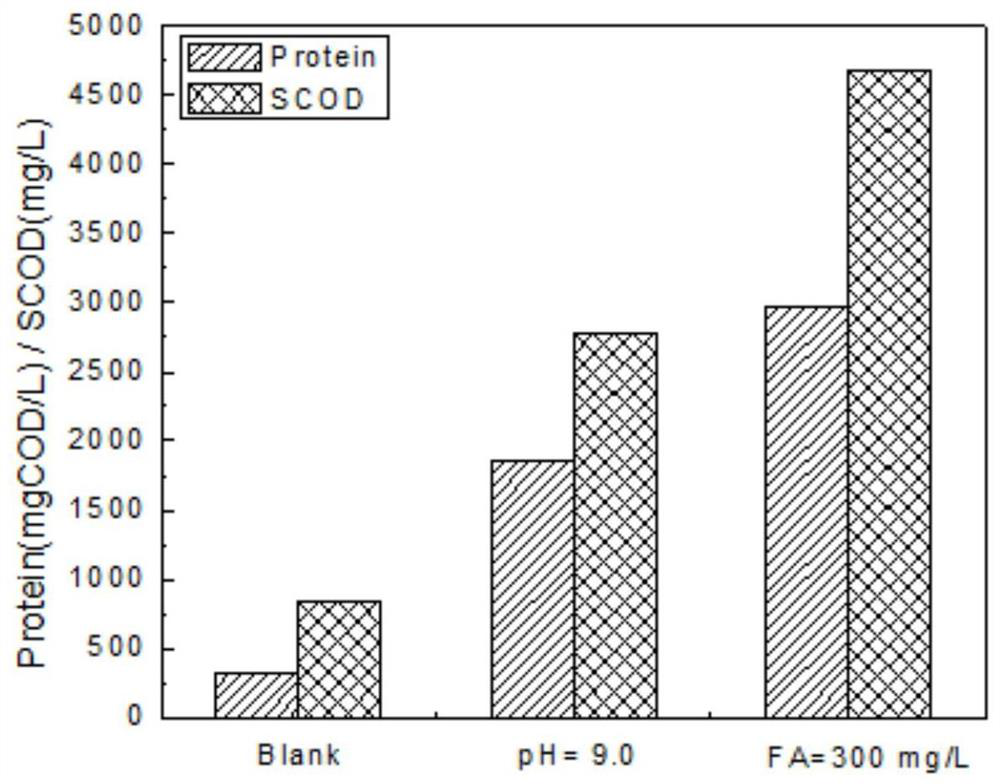

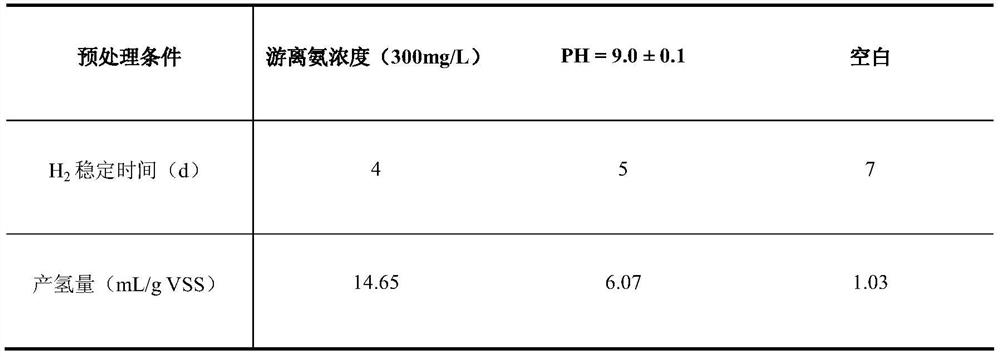

[0028] (2) Pretreatment: from step (1) was obtained in 500mL based fermented anaerobic reactor, adding thereto ammonium chloride 0.8173g, controlled temperature during 37 ± 0.5 ℃, constantly adjusting the pH = 9.0 ± 0.1 the pre-processing stage free ammonia concentration of 300mg / L, and maintain 12h.

[0029] (3) anaerobic fermentation: After 12h, flushed with nitrogen 1.5min to the anaerobic reactor to drive off oxygen, sealed put in a thermostatic shaker-incubator anaerobic hydrogen production, set at a temperature of 37 ℃, shaking rate It was 130rpm / min. 8 days fermentation process, the hydrogen content in the fermentation process once every 12h measured by gas chro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com