Microwave pretreatment method capable of improving anaerobic fermentation efficiency of vinegar residues

An anaerobic fermentation and pretreatment technology, applied in fermentation, waste fuel, etc., can solve the problems of long gas production cycle, low gas production rate, and low biotransformation rate, and achieve the effect of improving efficiency and speeding up the hydrolysis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1(30

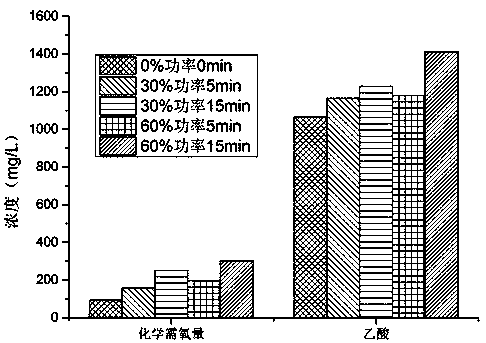

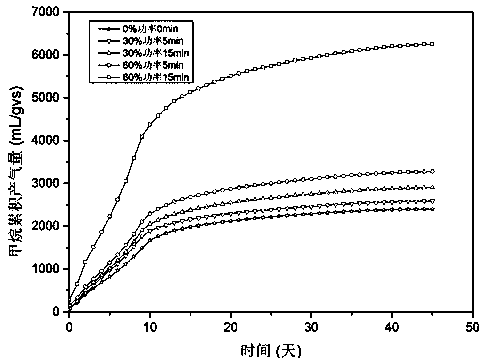

[0022] Example 1 (30% power for 5 minutes)

[0023] A microwave pretreatment method for improving the efficiency of anaerobic fermentation of vinegar residues, comprising the following steps:

[0024] S1. The vinegar grains from a vinegar factory in Jiangsu Province were taken for the following anaerobic fermentation. The pH of the vinegar grains was 3.8, the solid content was 33%, and the crude fiber content was 27%.

[0025] S2. Take 80g of vinegar grains and mix them with 80g of water, and treat them under the microwave condition of 180W (30% power) for 5min.

[0026] S3. Take a small amount of fresh vinegar grains and add it to the anaerobic activated sludge, and carry out domestication at 35°C. The initial TS is controlled at 4%, and the initial pH is controlled at 7.5. When the methane content of the system reaches more than 65%, the domestication is successful.

[0027] S4. Inoculate the anaerobic activated sludge acclimated in step S3 into the mixed solution of vinega...

Embodiment 2

[0029] Example 2 (30% power for 10 minutes)

[0030] A microwave pretreatment method for improving the efficiency of anaerobic fermentation of vinegar residues, comprising the following steps:

[0031] S1. Mix vinegar grains with a mass ratio of 1:1 with water, stir evenly, and pretreat under 180W (30% power) microwave conditions for 10 minutes;

[0032] S2. Add 40g of fresh vinegar grains to 70L of anaerobic activated sludge, and place it at 33°C for domestication. The initial TS is controlled at 3%, and the initial pH is controlled at 7.3. When the methane content of the system reaches more than 65%, the anaerobic activity If the sludge is domesticated successfully, proceed to step S3;

[0033] S3. Inoculate the anaerobic activated sludge successfully domesticated in step S2 into the vinegar residue mixture treated in step S1, the inoculum amount is 60%, and place it in a fermenter, put it in a water bath, and control the temperature at 33°C Anaerobic fermentation 45d.

...

Embodiment 3

[0035] Example 3 (30% power for 15 minutes)

[0036] A microwave pretreatment method for improving the efficiency of anaerobic fermentation of vinegar residues, comprising the following steps:

[0037] S1. The vinegar grains from a vinegar factory in Jiangsu Province were taken for the following anaerobic fermentation. The pH of the vinegar grains was 3.5, the solid content was 31%, and the crude fiber content was 26.38%.

[0038] S2. Take 80g of vinegar grains and mix them with 80g of water, and treat them under the microwave condition of 180W (30% power) for 15min.

[0039] S3. Take a small amount of fresh vinegar grains and add it to the anaerobic activated sludge, and carry out domestication at 35°C. The initial TS is controlled at 4%, and the initial pH is controlled at 7.5. When the methane content of the system reaches more than 65%, the domestication is successful.

[0040] S4. Inoculate the anaerobic activated sludge acclimated in step S3 into the mixed solution of v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com