Novel method for extracting stevioside efficiently and quickly

A technology of steviol glycosides and a new method, which is applied in the field of extraction of food additives, can solve the problems of long extraction time, many process steps, low productivity and production rate, etc., shorten the process time, improve the extraction efficiency, and improve the recovery rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

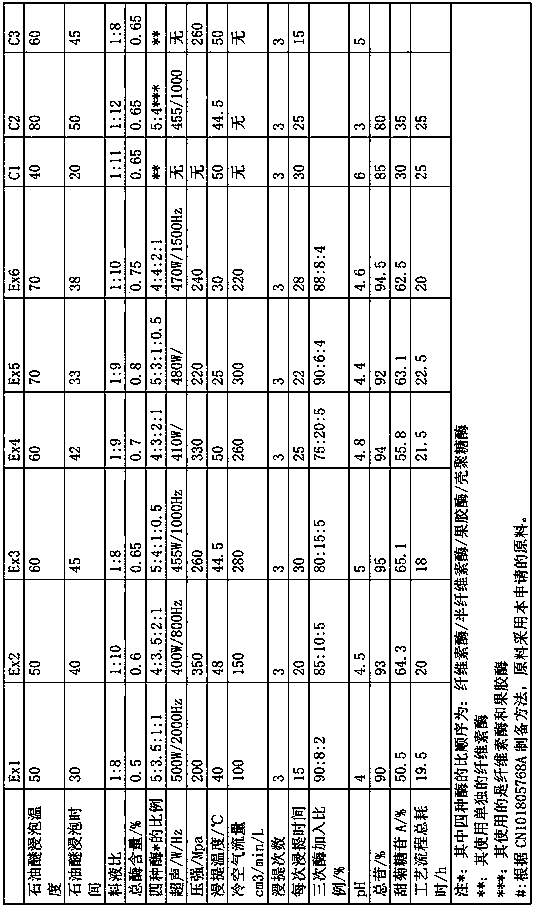

Examples

Embodiment 1

[0036] A new method for extracting steviol glycosides efficiently and quickly, 1) dry and crush stevia leaves through a 200-mesh sieve; 2) soak in petroleum ether for 30 minutes under stirring at 50°C; 3) filter the filtrate in a compound enzyme-containing The sodium citrate solution of pH=4 carries out leaching treatment, and wherein compound enzyme is cellulase / hemicellulase / pectinase and chitosanase, and the ratio of above-mentioned four kinds of compound enzymes is 5:3.5:1: 1. The ratio of filtrate (by dry weight) to solvent water is 1:8; the content of compound enzyme in the extract is 0.5%, the extraction temperature is 40°C, three extractions, each extraction time 15min; wherein the enzyme addition method is a stepwise decreasing addition method, which is also added in three times, the first addition accounts for 90% of the total enzyme content, the second addition is 8%, and the third addition is 2%; The extraction equipment is carried out under high pressure, the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com