Patents

Literature

32results about How to "Improve and strengthen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

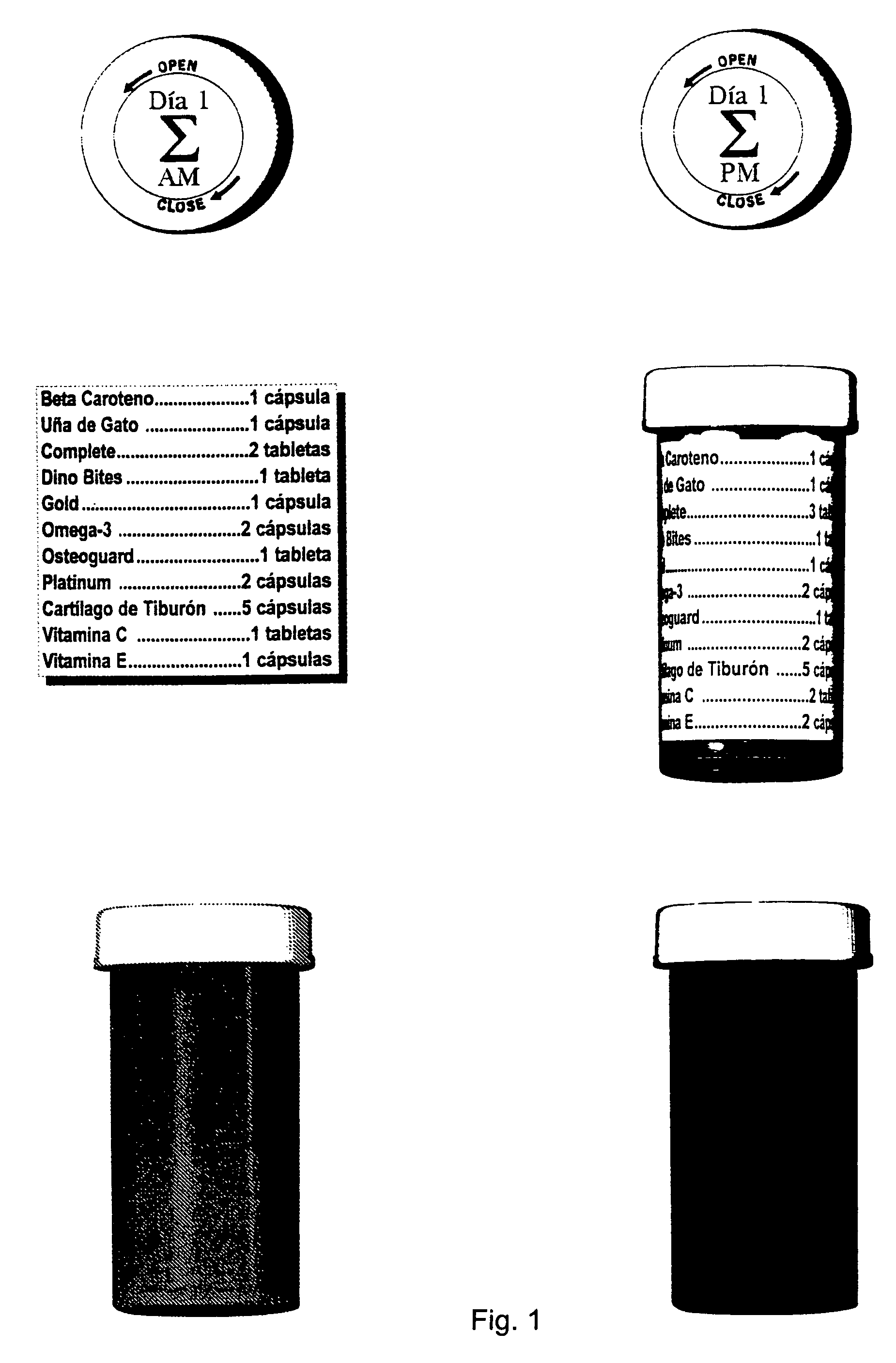

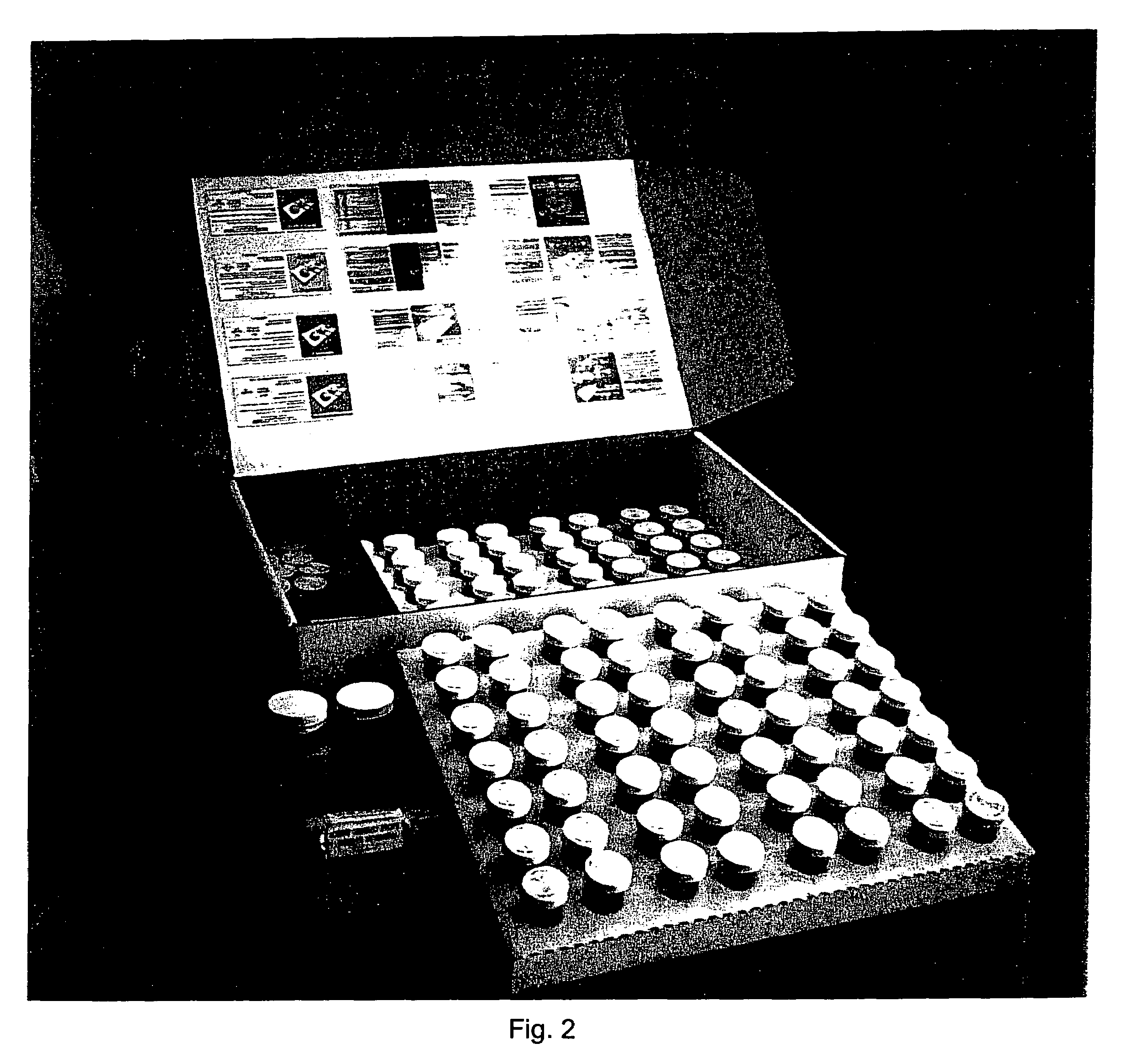

Health enhancement method

InactiveUS7273607B2Slow and stop growthEnhance the body's natural defense systemsOrganic active ingredientsBiocideDiseaseNatural product

A health enhancement system establishing a health enhancement program through which may be provided a group of natural products, vitamins and minerals, amino acids, herbs and essential oils that may be helpful in aiding the body in fighting the growth of cancers and the progression of other diseases and in reducing the negative side effects of cancer and cancer treatment, and other diseases and their treatment. At least one embodiment of the invention involves a packaging system of the group of natural products, vitamins and minerals, amino acids, herbs and essential oils that the health enhancement system may comprise.

Owner:SCHAKEL LEGAL REPRESENTATIVE KARL G +1

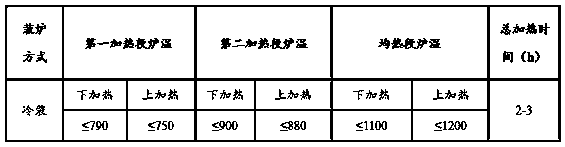

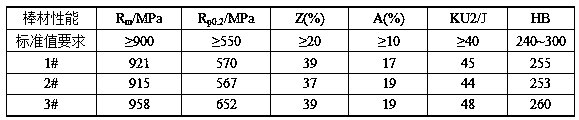

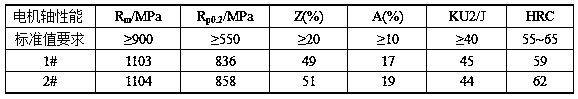

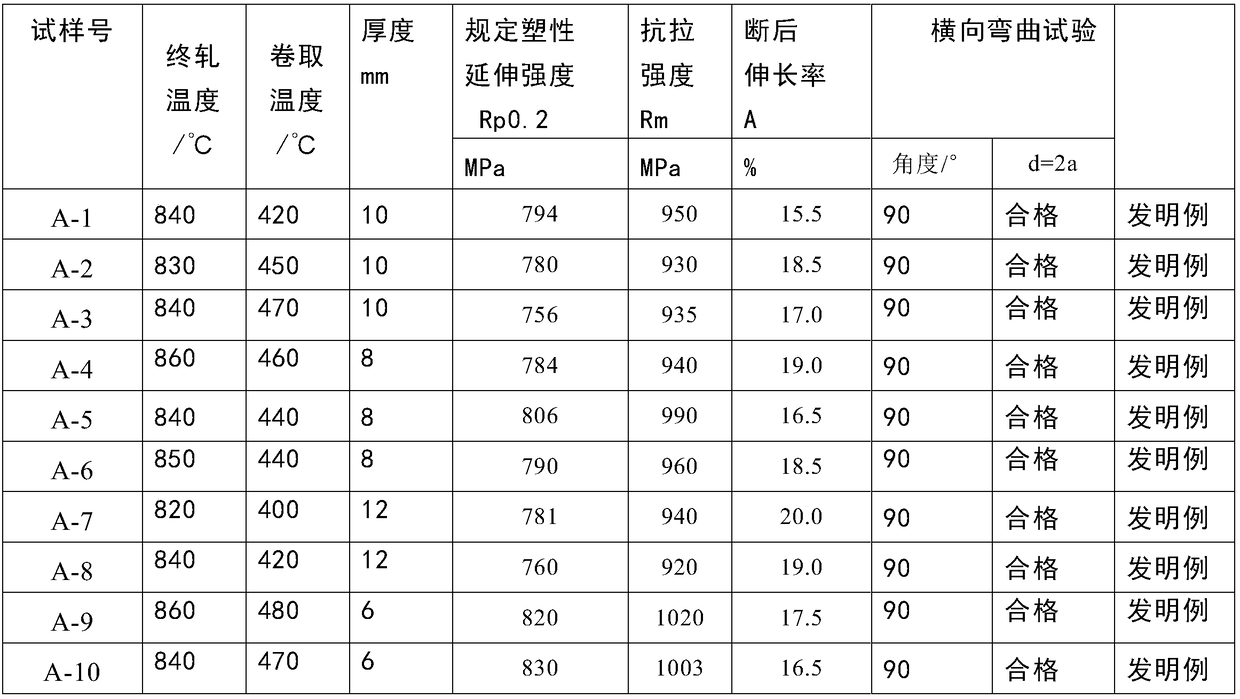

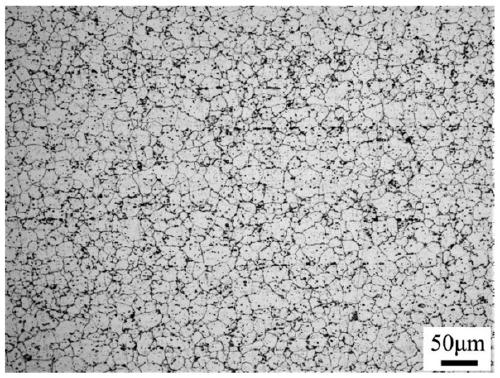

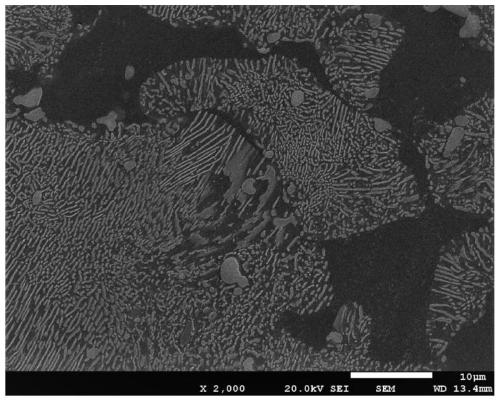

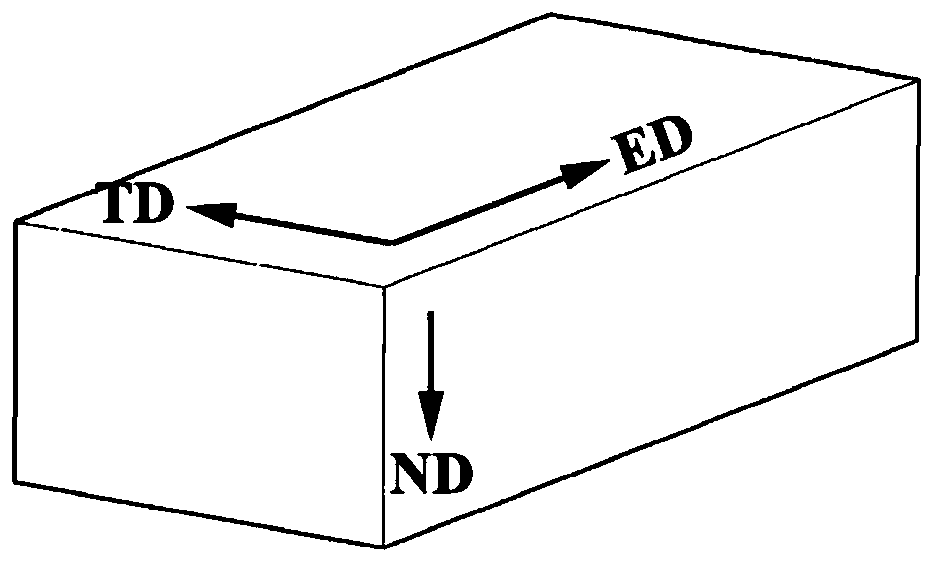

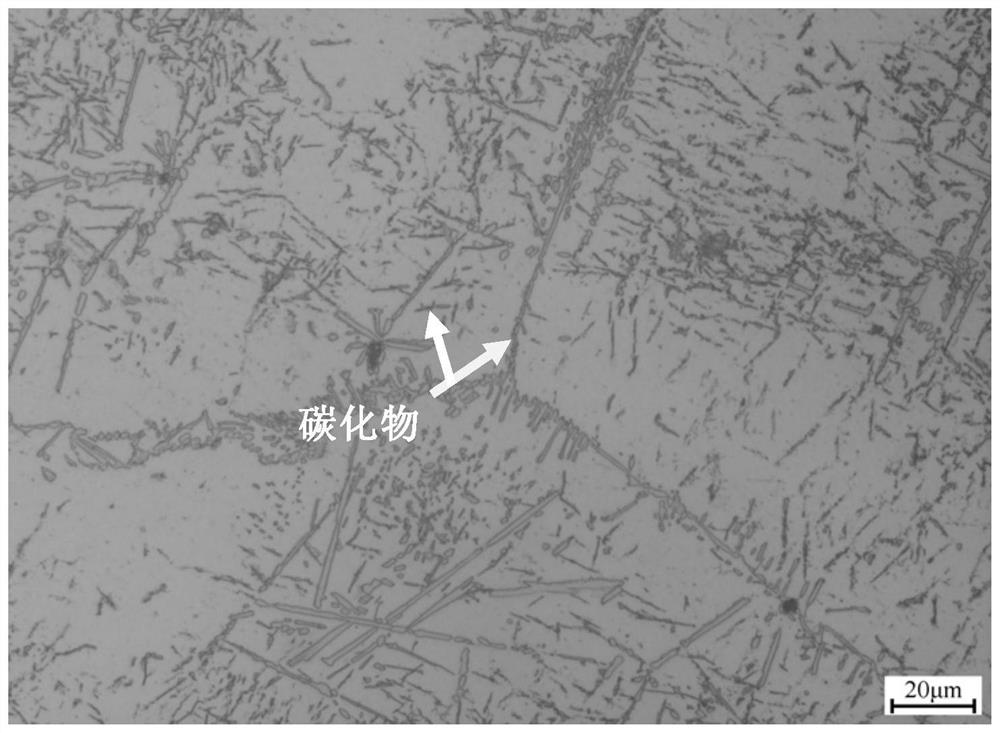

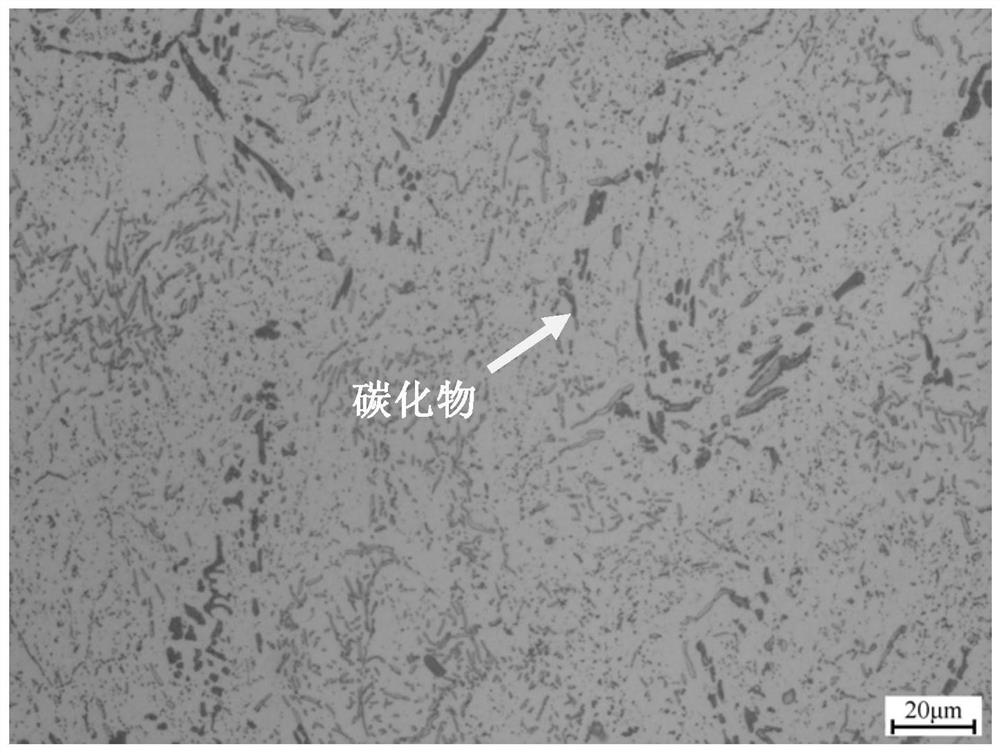

Non-quenched and tempered steel for motor shaft of new energy electric vehicle and production method of non-quenched and tempered steel

ActiveCN109439836AImprove and strengthenReduce manufacturing costManufacturing convertersManufacturing cost reductionChemical composition

The invention discloses non-quenched and tempered steel for a motor shaft of a new energy electric vehicle and a production method of the non-quenched and tempered steel. The steel is prepared from the following chemical compositions in percentage by weight: 0.45-0.51% of C, 0.30-0.55% of Si, 1.0-1.25% of Mn, no more than 0.020% of P, 0.010-0.025% of S, 0.10-0.20% of Cr, 0.20-0.30% of Ni, 0.015-0.035% of Al, 0.08-0.12% of V, no more than 0.035% of Nb, 0.010-0.025% of Ti, 130-170 ppm of N, and the balance of original Fe. According to the non-quenched and tempered steel for the motor shaft of the new energy electric vehicle and the production method of the non-quenched and tempered steel, it can be known that through perfect combination of optimization design of the chemical compositions anda controlled rolling and cooling process technology (rolling parameters), the smelting process, the initial rolling temperature, the finish rolling temperature and the cooling mode of a formula are strictly controlled, thus production of the easy-turning and high-toughness non-quenched and tempered steel for the motor shaft is achieved, the developed motor shaft can be highly reinforced, the manufacturing cost can further be lowered (20% of the procedure cost is saved), and the production period can be shortened (the production time is shortened by one day).

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

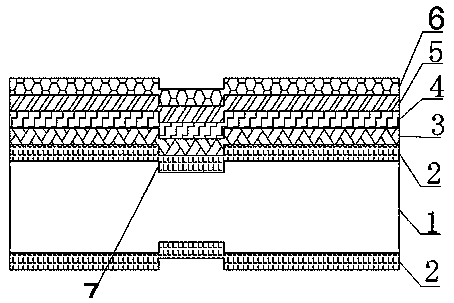

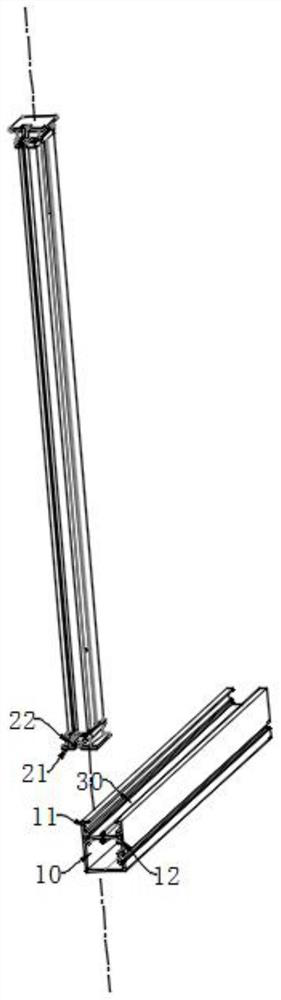

Cleaning cloth that can be joined to a mop base

ActiveCN104321003AEasy to twistImprove and strengthenCarpet cleanersFloor cleanersMechanical engineeringTextile

Owner:TTS手推车装置有限公司

Corrosion inhibitor capable of preventing high-strength low-alloy steel from being corroded in chloride-containing corrosive medium

InactiveCN106544679AInhibition of localized corrosionMitigate uniform corrosionRare-earth elementCerium nitrate

The invention provides a corrosion inhibitor capable of preventing high-strength low-alloy steel from being corroded in a chloride-containing corrosive medium and belongs to the field of inhibitors. The corrosion inhibitor comprises phosphate with the concentration being 300-600 ppm, sodium tripolyphosphate with the content being 200-400 ppm, sodium phosphate with the content being 100-200 ppm, a sodium nitrite compound with the concentration being 20-60 ppm and a cerium compound with the concentration being 30-80 ppm, wherein the cerium compound is cerium chloride, or cerium sulfate or cerium nitrate, and the valence state of cerium is +3. The corrosion inhibitor containing the rare earth element, namely cerium with the valence state being +3, is developed for preventing the high-strength low-alloy steel from being corroded in the chloride-containing corrosive medium so as to meet requirements of oceaneering and ship engineering in the ocean resource development process.

Owner:BEIJING UNIV OF CHEM TECH +1

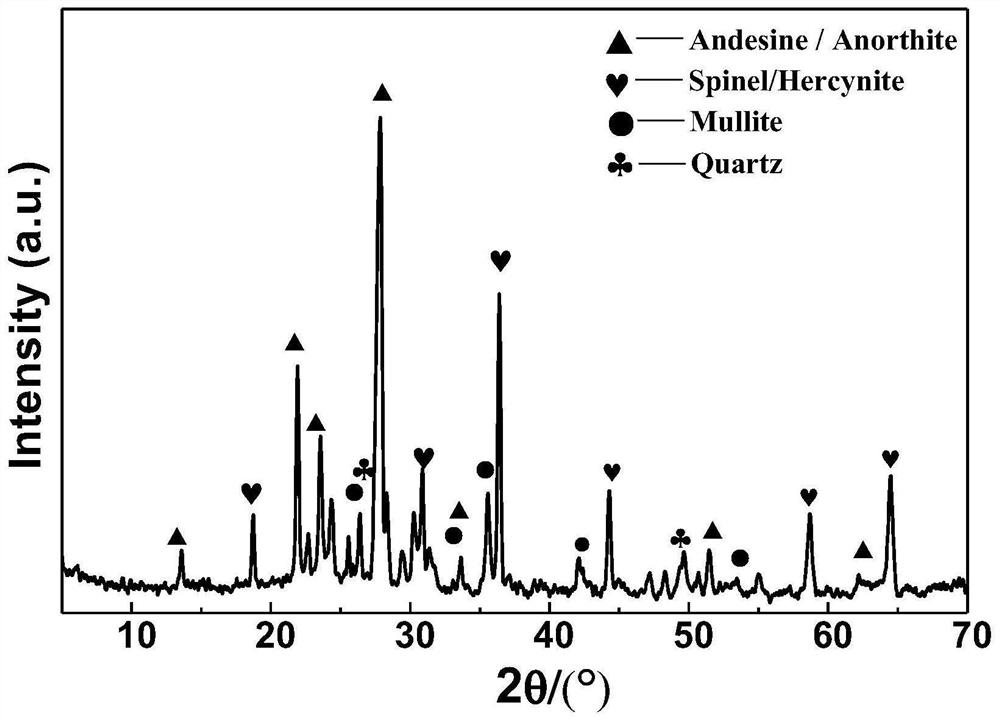

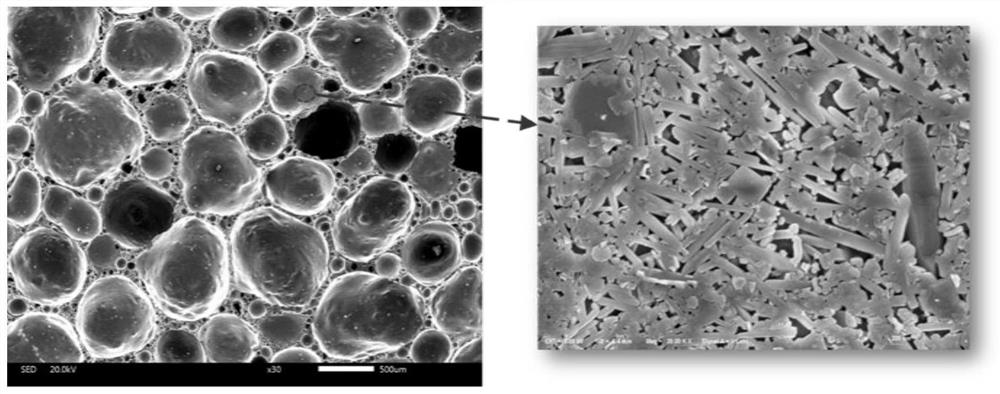

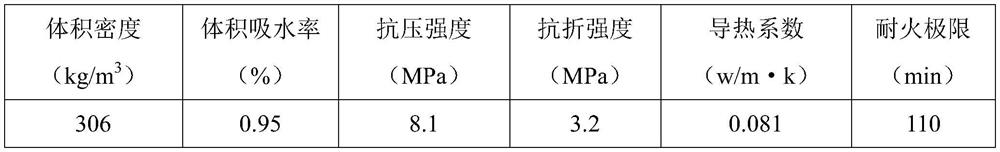

Method for preparing high-strength foamed ceramic from solid waste

ActiveCN112811923AReduce manufacturing costImprove protectionCeramic materials productionCeramicwareFiberMaterials preparation

The invention relates to the technical field of ceramic material preparation, in particular to a method for preparing high-strength foamed ceramic by using solid wastes, which comprises the following steps: by taking industrial solid wastes such as coal-series solid wastes, metal tailings and the like as main raw materials and chromium-containing sludge as a crystalline phase regulating agent, adding 0.1-1.0% of composite foaming agent and 0.05-0.6% of dispersing agent, performing dry ball-milling and mixing to prepare uniform powder, adding 0.5-5% of chopped fibers as a reinforcing agent, performing wet-process high-speed stirring to prepare uniformly dispersed slurry, and then performing drying and powder preparation, die-filling and firing, cooling and crystallizing, and cutting and forming to prepare the product. According to the method for preparing the high-strength foamed ceramic by using the solid wastes, the problems of high raw material cost and poor mechanical property of the existing foamed ceramic are solved, and high value-added utilization of the solid wastes is realized.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

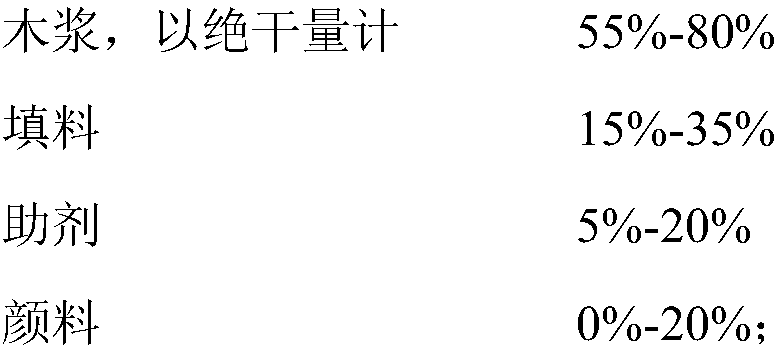

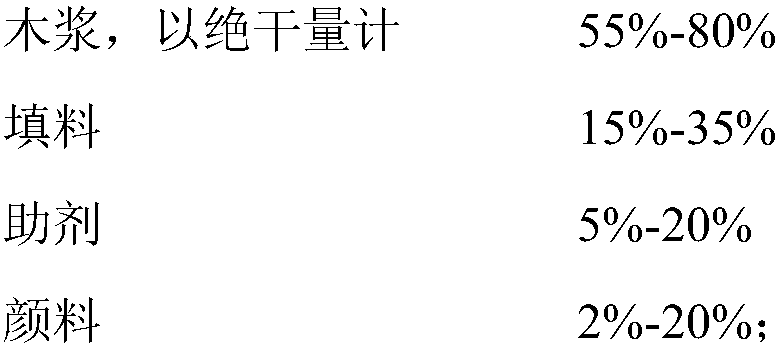

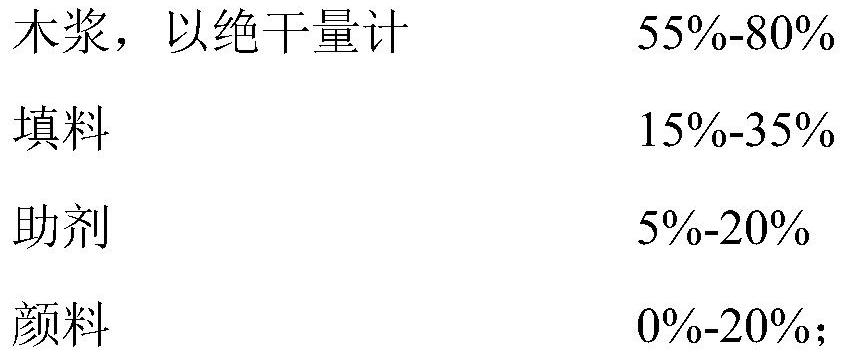

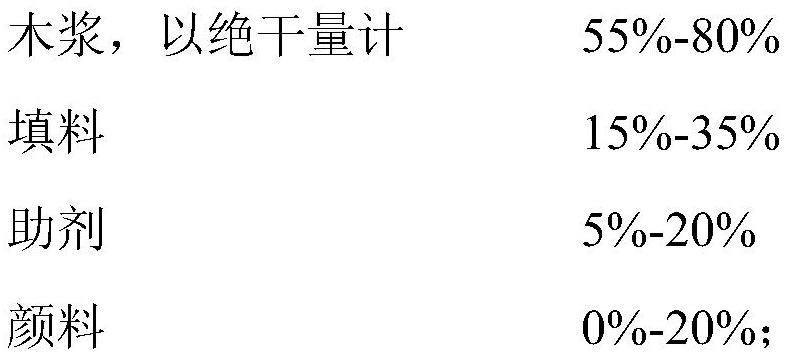

Overcoating base paper used for outdoor highly-strengthened plate and preparation method of overcoating base paper

ActiveCN108130815AIncrease coverageImprove breathabilitySpecial paperReinforcing agents additionFiberPapermaking

The invention belongs to the technical field of papermaking, and in particular relates to overcoating base paper used for an outdoor highly-strengthened plate and a preparation method of the overcoating base paper. The base paper is prepared from the following raw materials: wood pulp, a filler, an auxiliary agent and a pigment, wherein the auxiliary agent is composed of sodium hydroxide, sulphuric acid, aluminium sulphate and a wet strength agent; and the filler is composed of titanium dioxide, magnesium silicate and kaolin. The prepared overcoating base paper used for the outdoor highly-strengthened plate provided by the invention has a good covering property, fiber distribution uniformity, fine paper surfaces, strong corrosion resistance, a high sun-proof grade, and high water washing color fastness; and after the base paper is impregnated with melamine for veneering, the base paper is impregnated into a solution with the pH of 3.5-10, and no phenomena such as blistering and deformation of the paper happen; and the sun-proof grade is 6 grade or more, and the water washing color fastness is high. The invention also provides a preparation method of the overcoating base paper usedfor the outdoor highly-strengthened plate, and the base paper has high practicability and scientific and reasonable operation, and is simple and practicable.

Owner:ZIBO OU MU SPECIAL PAPER

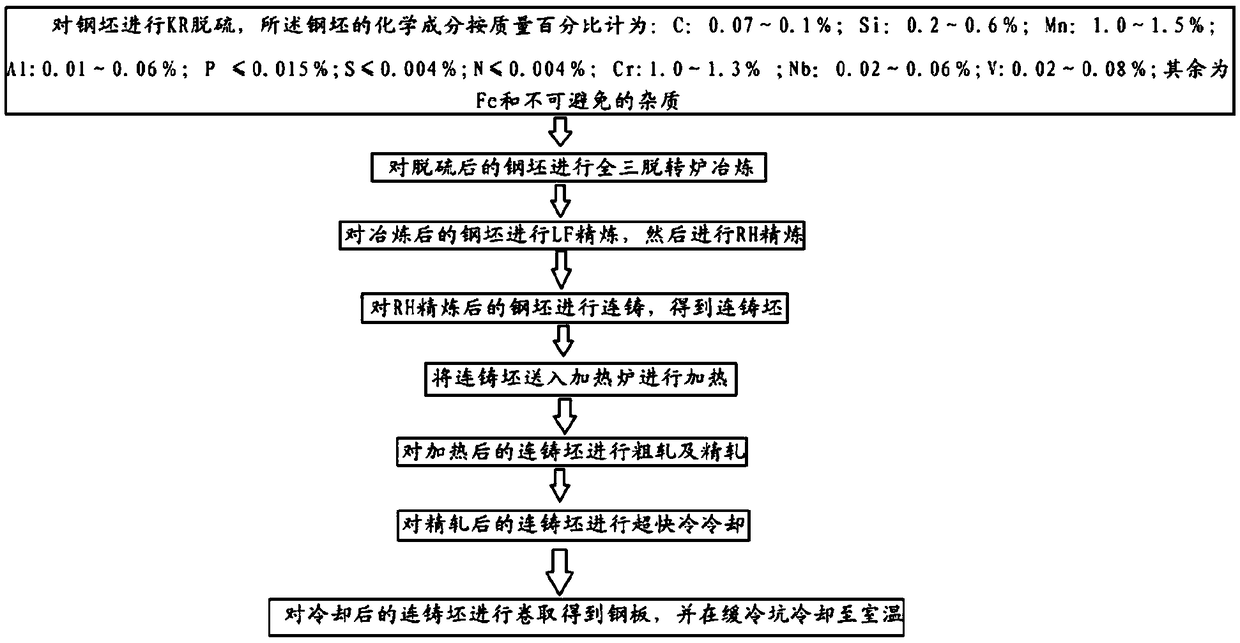

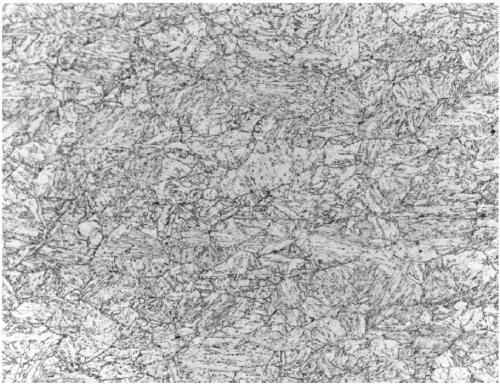

900-MPa-grade anti-riot steel plate for ATM machine and manufacturing method thereof

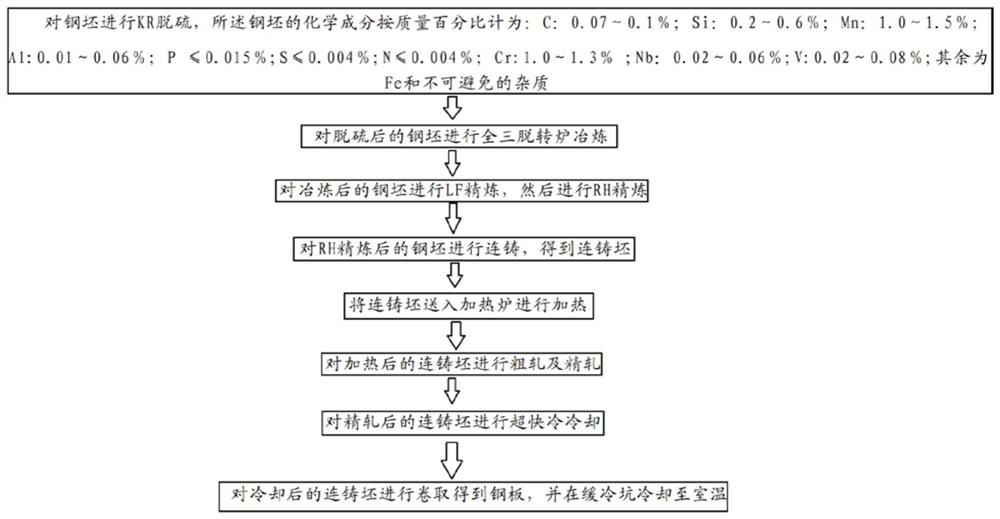

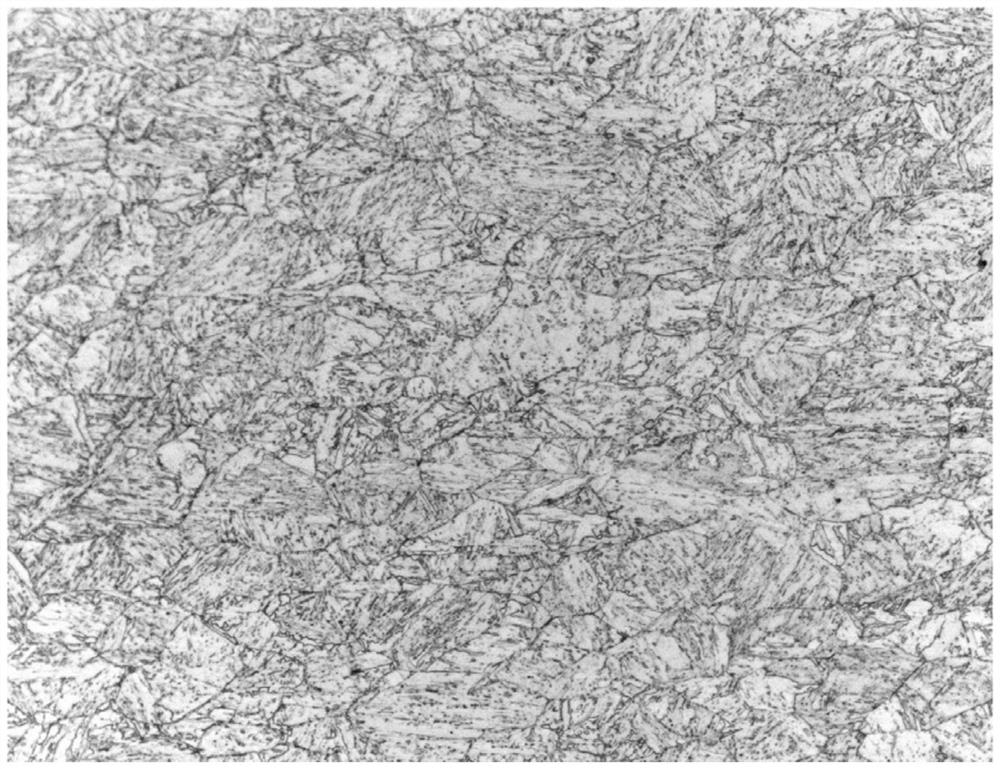

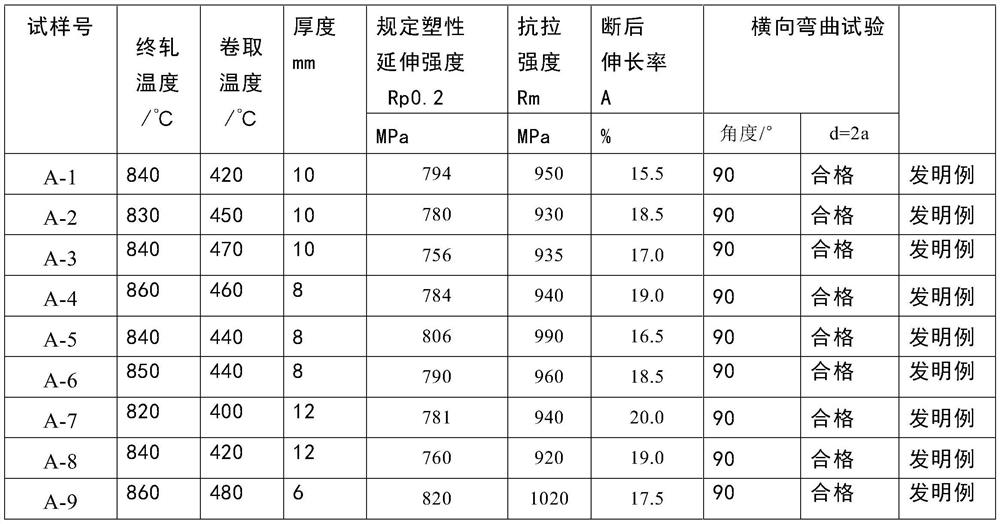

The invention discloses a 900-MPa-grade anti-riot steel plate for an ATM machine and a manufacturing method thereof, belonging to the field of preparation technology for metal materials. The 900-MPa-grade anti-riot steel plate comprises the following chemical components by mass: 0.07 to 0.1% of C, 0.2 to 0.6% of Si, 1.0 to 1.5% of Mn, 0.01 to 0.06% of Al, no more than 0.015% of P, no more than 0.004% of S, no more than 0.004% of N, 1.0 to 1.3% of Cr, 0.02 to 0.06% of Nb and 0.02 to 0.08% of V, with the balance being Fe and unavoidable impurities. The 900-MPa-grade anti-riot steel plate prepared by using the manufacturing method in the invention has yield strength reaching the 750 MPa grade, tensile strength reaching 900MPa or more and elongation A reaching 15% or more, and also has good cold bending and welding performance.

Owner:SHOUGANG CORPORATION

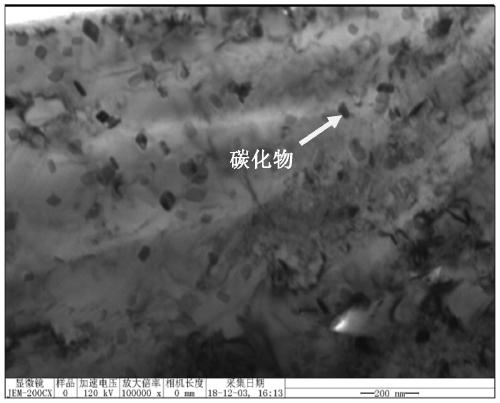

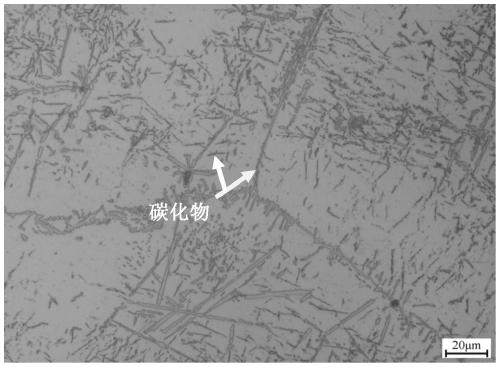

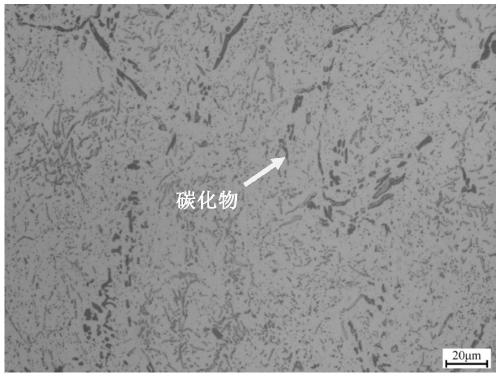

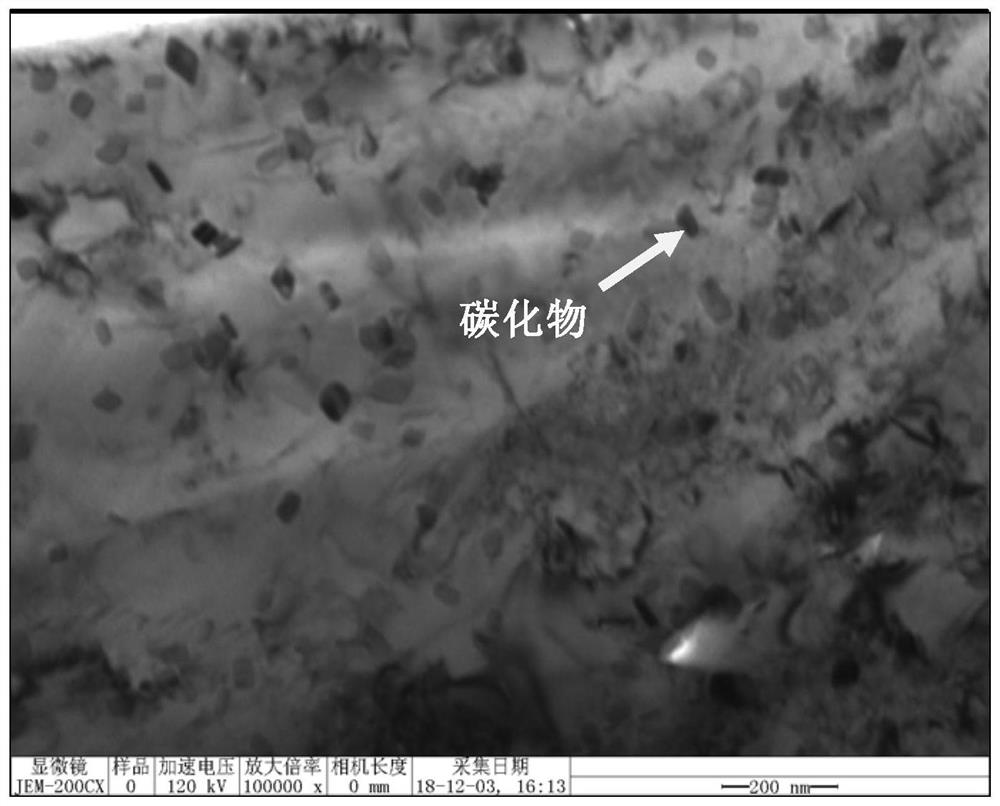

Preparation method for medium- and high-strength niobium alloy powder with intracrystalline-strengthened nano-scale carbide

The invention discloses a preparation method for a medium- and high-strength niobium alloy powder with an intracrystalline-strengthened nano-scale carbide. According to the method, NbC powder with a mass purity of greater than 99.95% and an average Fisher particle size of less than 3[mu]m is taken as a strengthening phase, the NbC powder and other alloy element powders are subjected to wet-millingand uniform mixing in a rolling ball-milling method, and then are dried, so that the medium- and high-strength niobium alloy powder with the intracrystalline-strengthened nano-scale carbide is obtained. According to the method, the NbC powder with a low particle size is adopted, the medium- and high-strength niobium alloy powder with the intracrystalline-strengthened nano-scale carbide is prepared through rolling ball-milling, and the carbide in a niobium alloy is subjected to second-phase refining and mostly distributed into crystals to form the nano-scale carbide, so that the strengtheningeffect of NbC is improved, then the strength of the niobium alloy is increased, the problem of difficulty to break and homogenize due to that a carbide is large in size and mostly distributed in a mesh shape along crystal boundaries, in a common preparation method for a niobium alloy with the strengthened carbide, is solved, and the insufficiency of the capacity of processing equipment is made up.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

980 MPa grade ATM machine anti-riot steel plate and fabrication method thereof

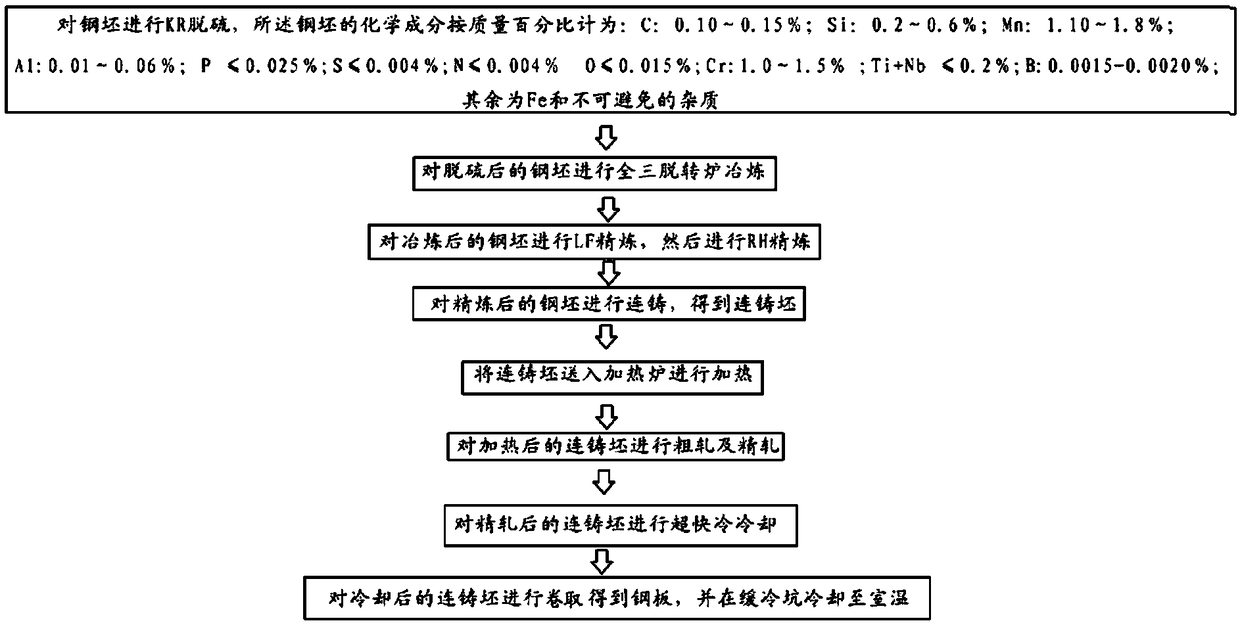

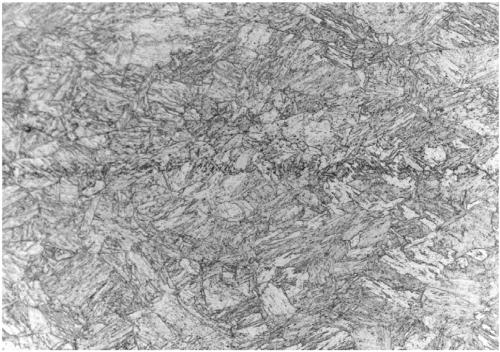

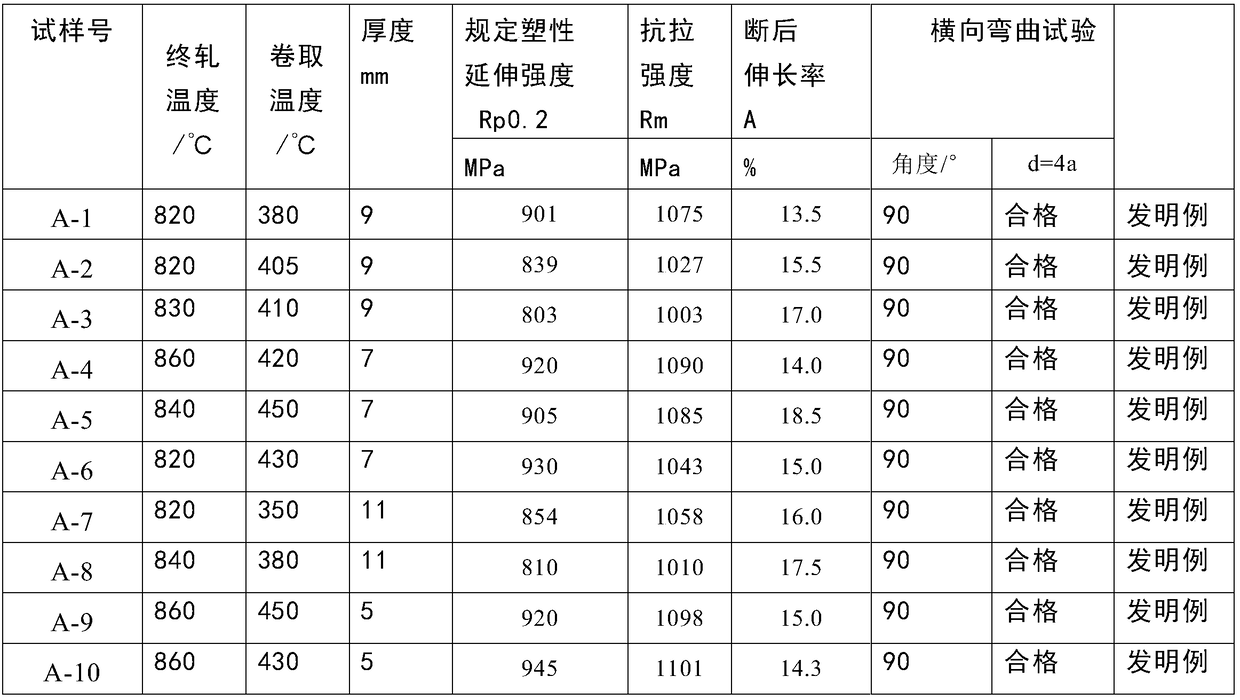

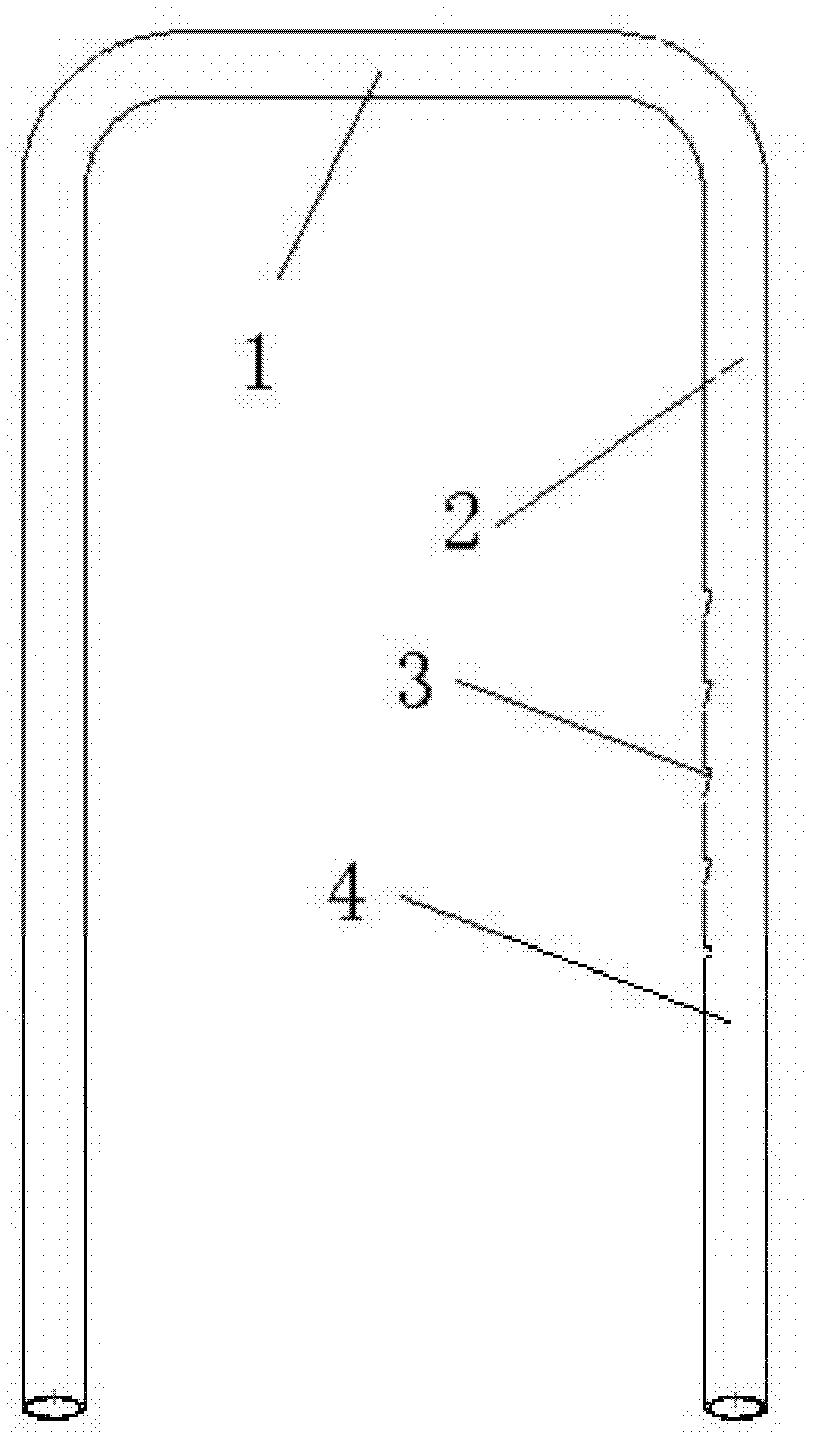

The invention discloses a 980 MPa grade ATM machine anti-riot steel plate and a fabrication method for the 980 MPa grade ATM machine anti-riot steel plate and belongs to the technical field of metal material preparation. The 980 MPa grade ATM machine anti-riot steel plate comprises the chemical ingredients of, in percentage by mass, 0.10-0.15% of C, 0.2-0.6% of Si, 1.10-2.0% of Mn, 0.01-0.06% of Al, less than or equal to 0.015% of P, less than or equal to 0.004% of S, less than or equal to 0.004% of N, 1.0-1.5% of Cr, less than or equal to 0.2% of Ti+Nb, 0.0015-0.0020% of B and the balance Feand unavoidable impurities. According to the steel plates obtained by the 980 MPa grade ATM machine anti-riot steel plate and the fabrication method for the 980 MPa grade ATM machine anti-riot steel plate, the yield strength reaches the 800 MPa grade, the tensile strength reaches 980 MPa or above, the ductility A reaches 13% or above, meanwhile, the obtained steel plates have good cold bending andwelding performance, and the alloy and process costs are both low.

Owner:SHOUGANG CORPORATION

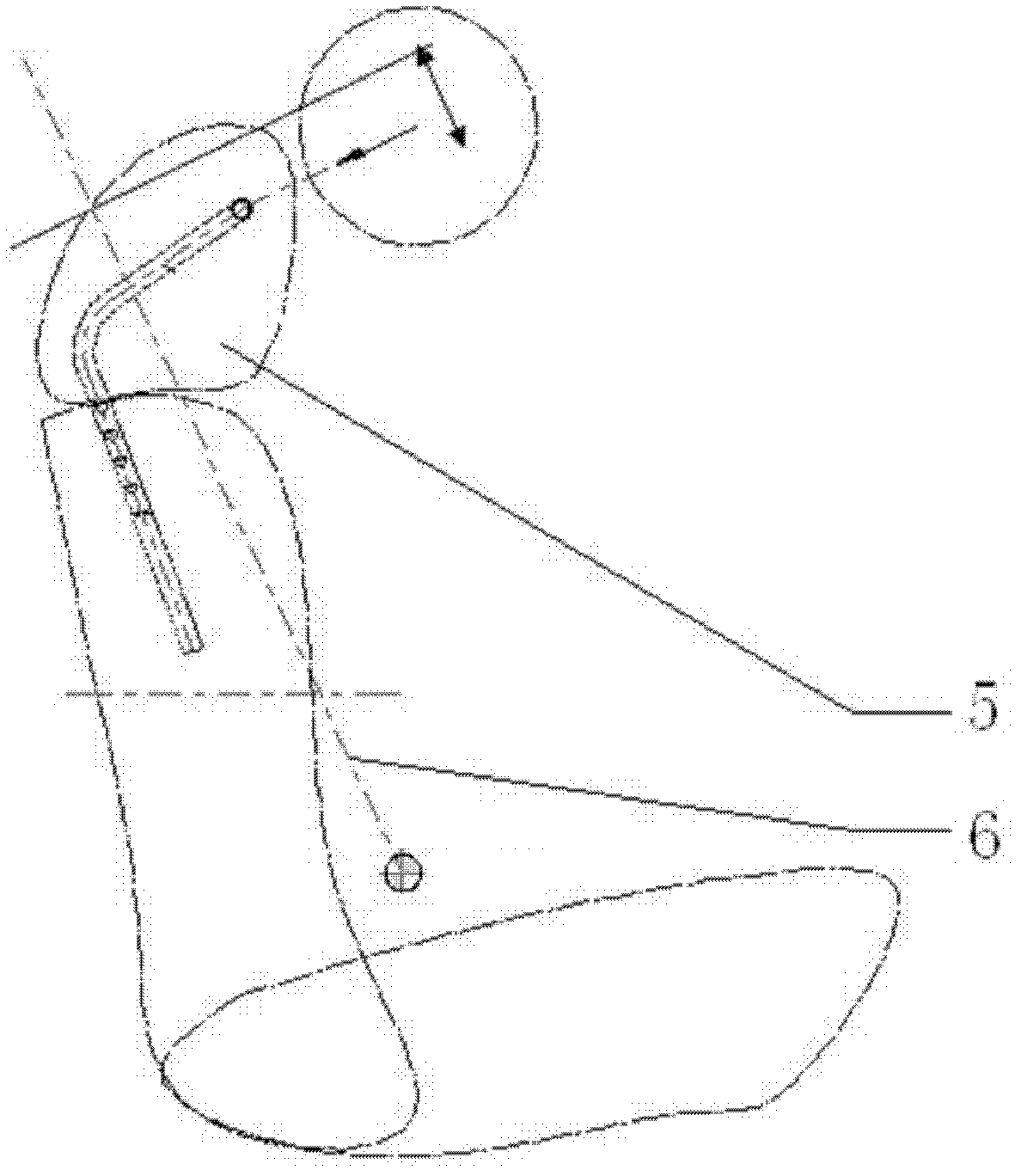

Lightweight fulcrum bar of headrest of automobile

InactiveCN102514512AReduce distortionImprove and strengthenSeat framesMaterial consumptionEngineering

The invention relates to a lightweight fulcrum bar of a headrest of an automobile, which comprises a supporting portion, a connecting portion and an adjusting guiding portion. The adjusting guiding portion consists of two bilateral steel tubes, the front end of the adjusting guiding portion is connected with the connecting portion, the connecting portion comprises two bilateral bent steel tubes, the two bent steel tubes are respectively connected with the two steel tubes of the guiding adjusting portion, the supporting portion is a bilateral U-shaped steel tube, and lower ends of two supporting legs of the U-shaped steel tube are respectively connected with upper ends of the two steel tubes of the guiding adjusting portion. The lightweight fulcrum bar of the headrest of the automobile is simple in structure, light in weight, high in material strength and low in material consumption, and cost can be saved.

Owner:NINGBO JIFENG AUTO PARTS

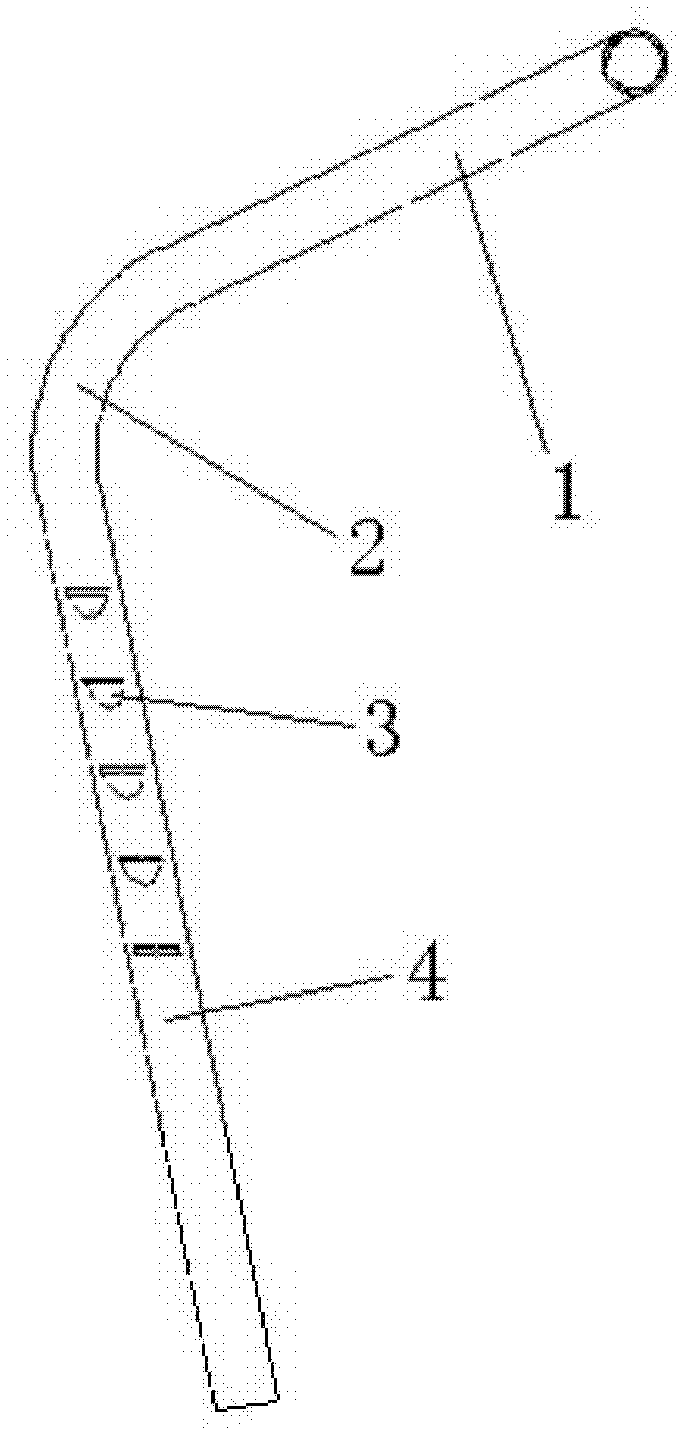

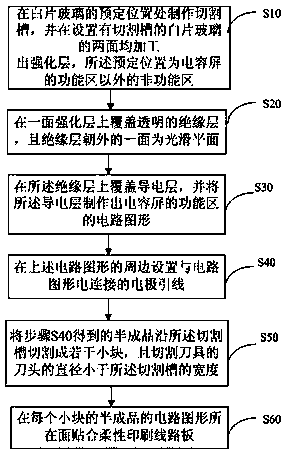

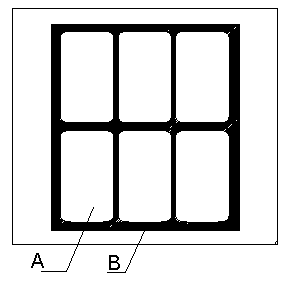

Manufacturing method of capacitive screen

InactiveCN103838443AImprove and strengthenImprove seismic performanceInput/output processes for data processingWork in processShock resistance

The invention provides a manufacturing method of a capacitive screen. The manufacturing method includes the steps that first, a cutting groove is manufactured in predetermined position of sheet glass, a toughened layer is machined on each of the two faces, provided with the cutting groove, of the sheet glass, and the predetermined position is a non-functional area beyond a functional area of the capacitive screen; second, the toughened layer on one face is covered with an insulating layer, and one face, towards outside, of the insulating layer is a smooth plane; third, the insulating layer is covered with a conductive layer, and the conductive layer is used for manufacturing a circuit pattern of the functional area of the capacitive screen; fourth, an electrode lead electrically connected with the circuit pattern is arranged on the periphery of the circuit pattern; fifth, the semi-finished product obtained in the fourth step is cut into a plurality of small blocks along the cutting groove, the diameter of a tool bit of a cutting tool is smaller than the width of the cutting groove; sixth, an FPC is attached to each face where the circuit pattern of each small block of the semi-finished product is located, and the FPCs are electrically connected with the electrode lead. The capacitive screen manufactured with the method is good in strength and shock resistance.

Owner:深圳市合力泰光电有限公司

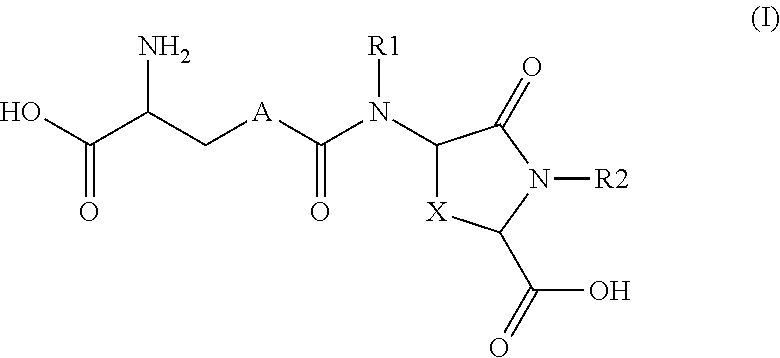

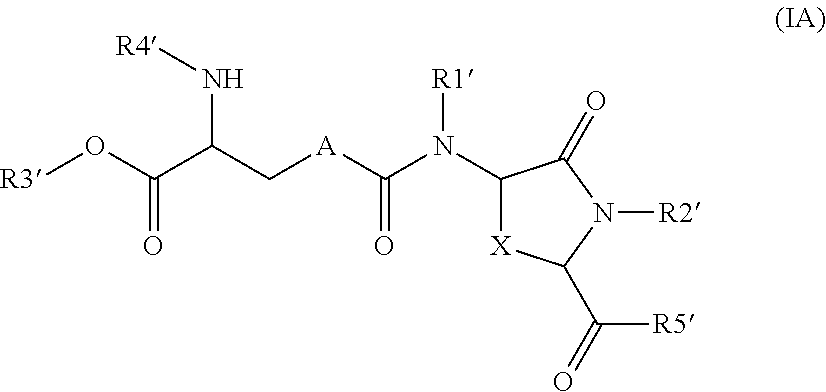

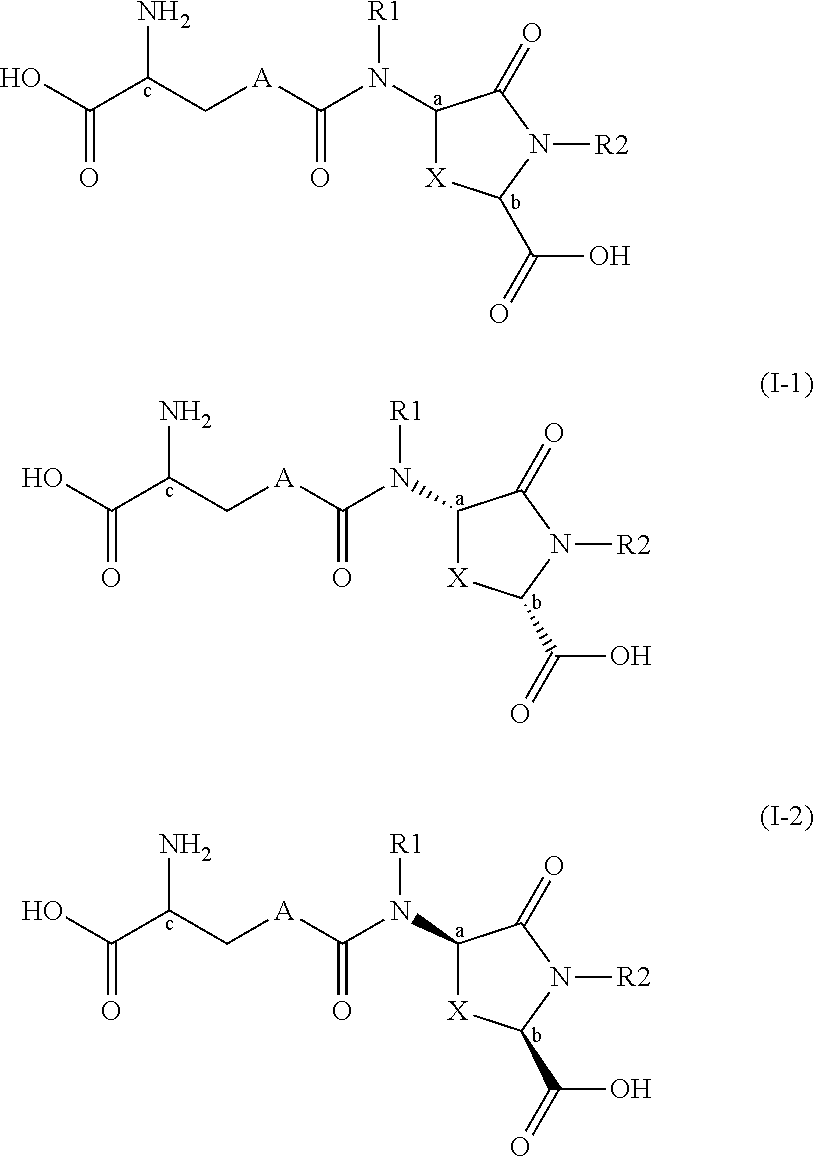

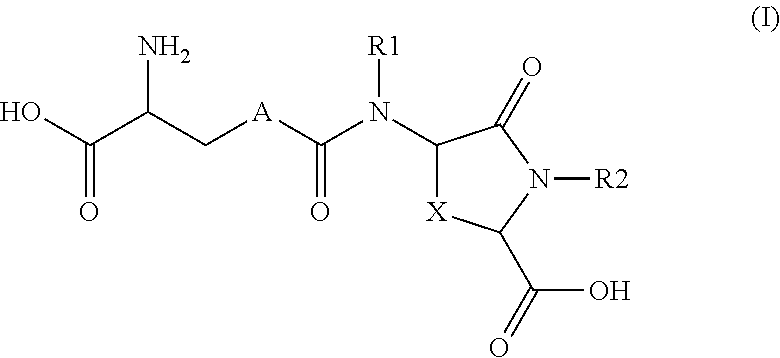

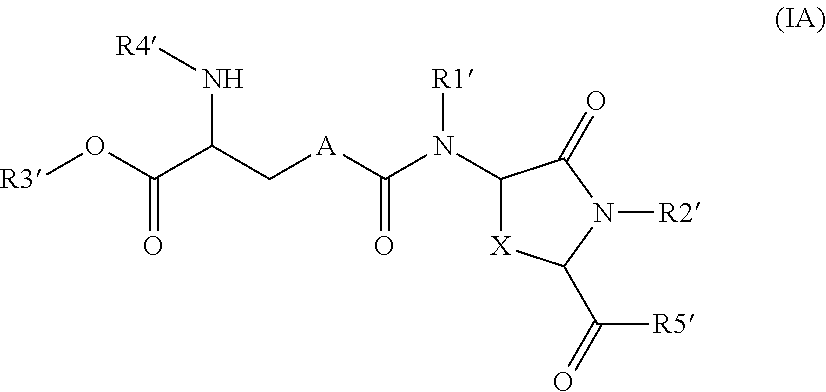

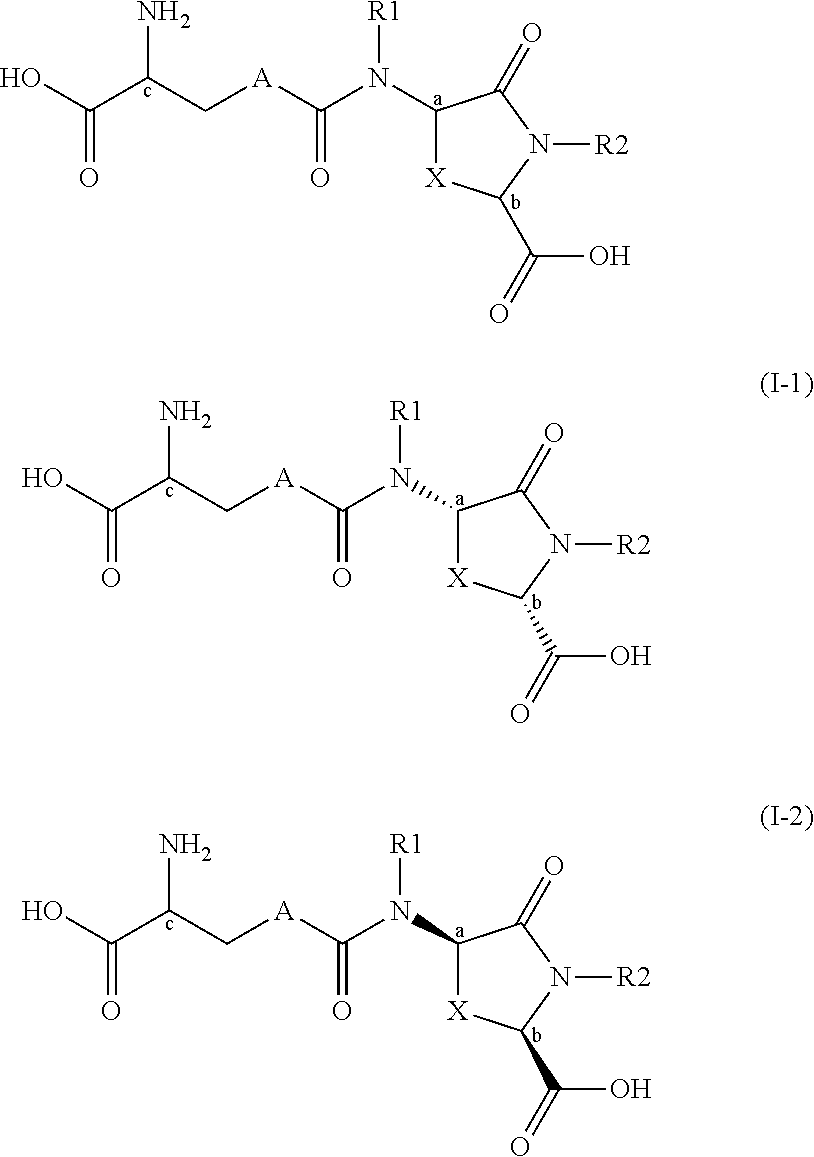

Lanthionine derivatives

ActiveUS8568814B2High activityFunction increaseMilk preparationOrganic active ingredientsLanthionineChemistry

The present invention provides a variety of compounds having a CaSR agonist activity which possesses a superior kokumi-imparting function, and more particularly provides a kokumi-imparting composition, which contains the foregoing compound, and / or another substance having a CaSR agonist activity, in combination. The present invention also provides a kokumi-imparting composition which includes a lanthionine derivative and / or another substance having a CaSR agonist activity.

Owner:AJINOMOTO CO INC

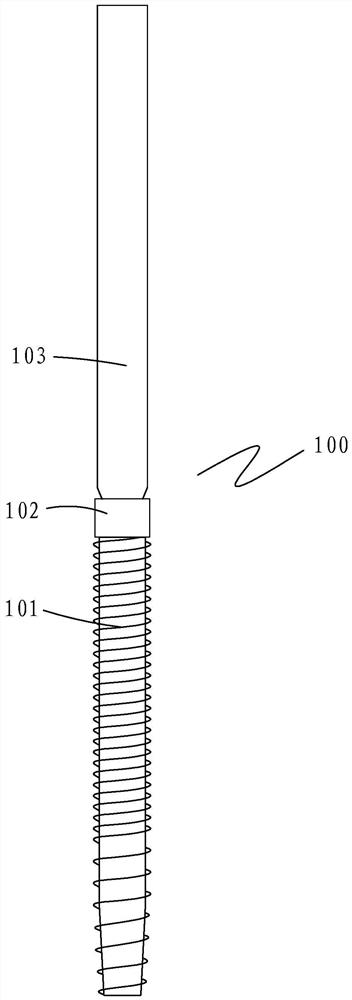

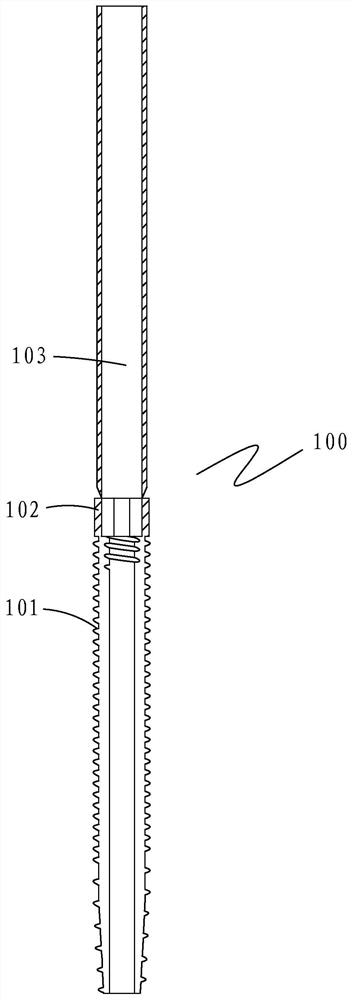

Bone cement channel pedicle anchor

PendingCN111685863AImprove and strengthenIncrease anchoring forceInternal osteosythesisFastenersEngineeringVertebral pedicle

The invention discloses a bone cement channel pedicle anchor. The bone cement channel pedicle anchor is a hollow cylinder and sequentially comprises a front-end threaded section, a nut section and a rear-end tail sleeve section, wherein the top end of the front-end threaded section is a tip end part, and the thread pitch of threads of the front-end threaded section is gradually reduced from the front end to the tail end; the length of the front-end threaded section is 4.5 cm; the length of the tail sleeve section is 10 cm; and the anchor is made of metallic titanium. According to the hollow bone cement channel pedicle anchor disclosed by the invention, a screw screwed into the pedicle can be firmly, stably and durably anchored in the pedicle, so that the strength, anchoring force and stability of bone cement blocks in a vertebral body are enhanced.

Owner:THE AFFILIATED HOSPITAL OF PUTIAN UNIV (THE SECOND HOSPITAL OF PUTIAN CITY)

Oxide-reinforced low-activation steel and manufacturing method thereof

ActiveCN113322407AStrong pinning dislocation strengthening effectImprove high temperature mechanical propertiesAdditive manufacturing apparatusFurnace typesWire rodMetallurgy

The invention discloses oxide-reinforced low-activation steel and a manufacturing method thereof. The manufacturing method comprises the following steps of in the smelting process of the low-activation steel, after the components of the low-activation steel reach the standard, adding Ti, Zr or Hf into the low-activation steel, after melting down, adding Y, uniformly stirring, and tapping and casting into a steel ingot; conducting homogenizing annealing and rolling on the steel ingot to obtain a wire rod; drawing the wire rod into a wire material; and conducting electric arc fuse forming on the wire material to obtain the oxide-reinforced low-activation steel, wherein ion gas and shielding gas adopted in the electric arc fuse forming process are both mixed gas of CO2 and Ar gas, and the cooling mode is natural cooling and solidification under the Ar protection atmosphere. According to the oxide-reinforced low-activation steel, the structure of the oxide reinforcement phase is more complex, and compared with existing oxide-reinforced low-activation steel, the oxide-reinforced low-activation steel has better high-temperature mechanical performance, and meanwhile, the processing method can rapidly achieve processing of the oxide-reinforced low-activation steel, and the yield of the oxide-reinforced low-activation steel can be increased.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

A kind of deformation heat treatment method of mg-al system precipitation strengthened magnesium alloy

The invention belongs to the technical field of metal strengthening and toughening and relates to a thermomechanical treatment method to acquire Mg17Al12 continuous precipitate of large volume fraction and high dispersity from precipitation-hardened Mg-Al alloys. According to the method, massive high-deformation energy storage areas are formed in a material through plastic deformation to further promote continuous precipitation; high-deformation energy storage areas capable of promoting continuous precipitation in Mg-Al precipitation-hardened alloys are mainly twin areas, so that a deformationpath most helpful for increasing twin area volume fractions is selected for performing deformation; by optimizing the parameters, such as the deformation path, strain capacity and aging system, Mg17Al12 continuous precipitate of high volume fraction and high dispersity is acquired and aging strengthening effect is thus improved.

Owner:GRIMAT ENG INST CO LTD

Computer network router with fastening mechanism

InactiveCN110198496AIncrease cooling rateEnsure ventilation and heat dissipationSelection arrangementsSurface mountingComputer network router

The invention discloses a computer network router with a fastening mechanism. The computer network router comprises a waterproof base, a signal cover and a network cable hole. A placement table is fixedly bonded to the top end of the waterproof base. A router shell is placed at the top end of the placement table; a heat dissipation mechanism is mounted on the placement table in a penetrating manner; the signal cover is installed on the outer ring of the router antenna. The network cable hole is formed in the edge of the side wall of the router shell, a first rotating shaft is installed on thesurface of the outer wall of the upper transverse strip, a lower transverse strip is fixedly bonded to the lower portion of the network cable hole, a second rotating shaft is installed on the surfaceof the outer wall of the lower transverse strip, and a second clamping ring is installed on the outer wall of the second rotating shaft. According to the computer network router with the fastening mechanism, the signal cover is installed in a semi-surrounding mode, a signal generated by working of the router can be released to a certain direction, signal strengthening in the direction of one sidewithout a shielding object can be improved, and a heat dissipation mechanism and a clamping mechanism are arranged in a matched mode, so that a user can use the router conveniently.

Owner:长沙开雅电子科技有限公司

A kind of anti-riot steel plate for 900mpa level ATM machine and its manufacturing method

The invention discloses a 900-MPa-grade anti-riot steel plate for an ATM machine and a manufacturing method thereof, belonging to the field of preparation technology for metal materials. The 900-MPa-grade anti-riot steel plate comprises the following chemical components by mass: 0.07 to 0.1% of C, 0.2 to 0.6% of Si, 1.0 to 1.5% of Mn, 0.01 to 0.06% of Al, no more than 0.015% of P, no more than 0.004% of S, no more than 0.004% of N, 1.0 to 1.3% of Cr, 0.02 to 0.06% of Nb and 0.02 to 0.08% of V, with the balance being Fe and unavoidable impurities. The 900-MPa-grade anti-riot steel plate prepared by using the manufacturing method in the invention has yield strength reaching the 750 MPa grade, tensile strength reaching 900MPa or more and elongation A reaching 15% or more, and also has good cold bending and welding performance.

Owner:SHOUGANG CORPORATION

Finishing base paper for outdoor high-strength board and preparation method thereof

ActiveCN108130815BIncrease coverageImprove breathabilitySpecial paperReinforcing agents additionFiberSilicic acid

The invention belongs to the technical field of papermaking, and in particular relates to overcoating base paper used for an outdoor highly-strengthened plate and a preparation method of the overcoating base paper. The base paper is prepared from the following raw materials: wood pulp, a filler, an auxiliary agent and a pigment, wherein the auxiliary agent is composed of sodium hydroxide, sulphuric acid, aluminium sulphate and a wet strength agent; and the filler is composed of titanium dioxide, magnesium silicate and kaolin. The prepared overcoating base paper used for the outdoor highly-strengthened plate provided by the invention has a good covering property, fiber distribution uniformity, fine paper surfaces, strong corrosion resistance, a high sun-proof grade, and high water washing color fastness; and after the base paper is impregnated with melamine for veneering, the base paper is impregnated into a solution with the pH of 3.5-10, and no phenomena such as blistering and deformation of the paper happen; and the sun-proof grade is 6 grade or more, and the water washing color fastness is high. The invention also provides a preparation method of the overcoating base paper usedfor the outdoor highly-strengthened plate, and the base paper has high practicability and scientific and reasonable operation, and is simple and practicable.

Owner:ZIBO OU MU SPECIAL PAPER

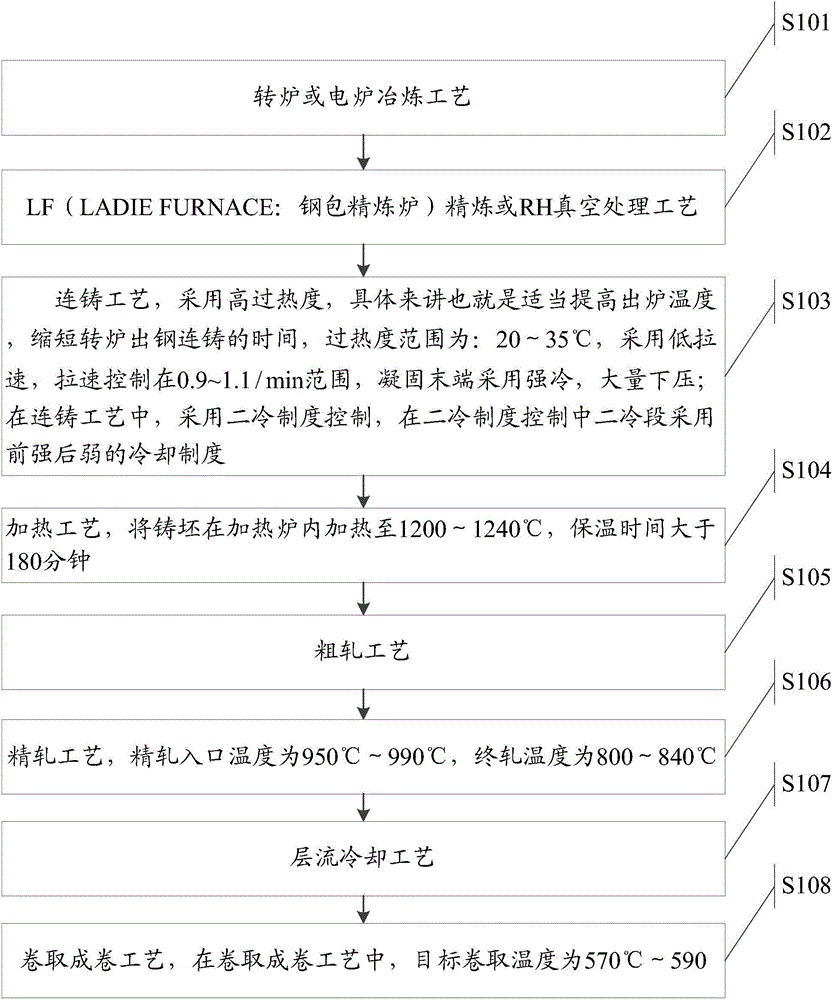

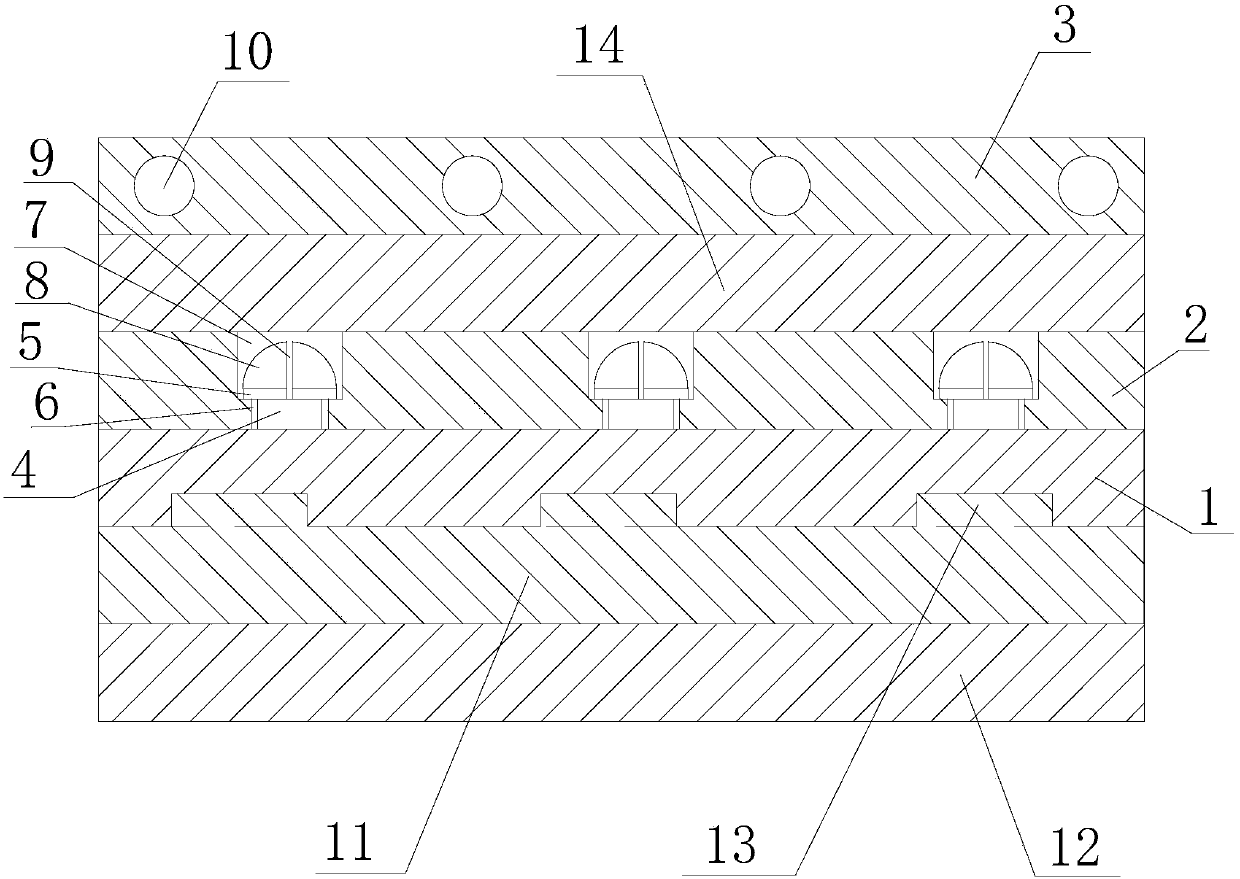

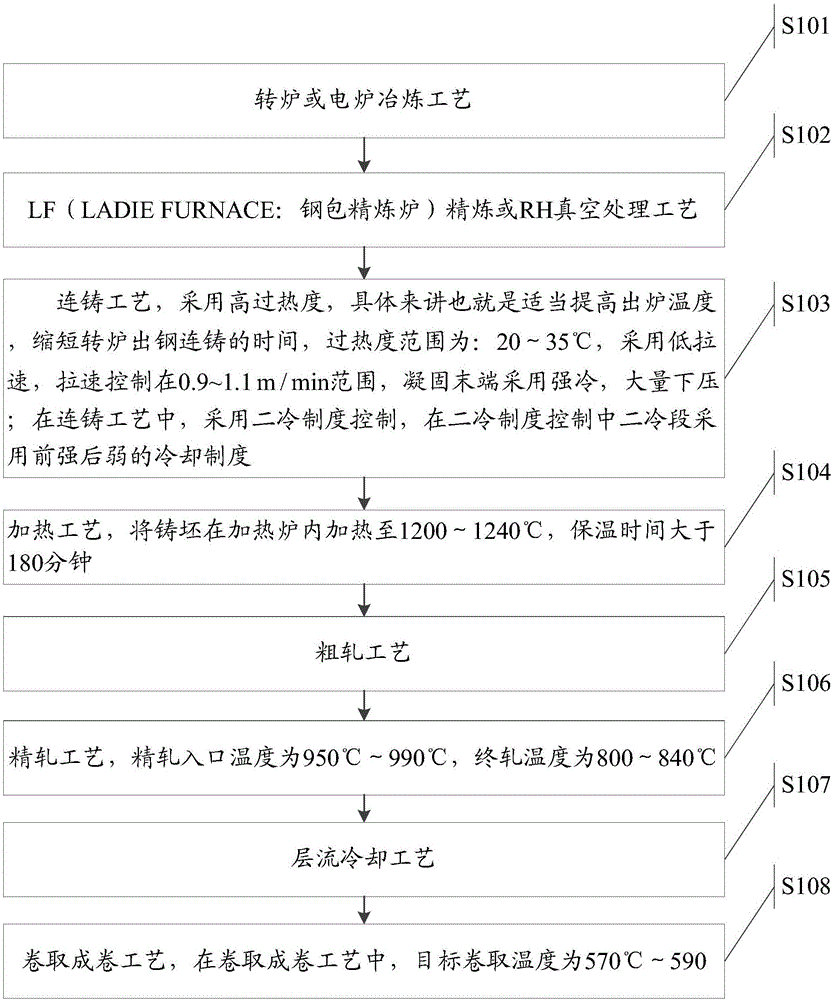

Method for producing steel for pipe fittings and steel for pipe fittings

The invention relates to the technical field of steelmaking and discloses a method for producing steel for pipe fittings and steel for the pipe fittings. The method comprises the following steps: smelting in a converter or an electric furnace, refining in an LF (ladle furnace) or RH vacuum treatment process, continuous casting, heating, rough rolling, finishing rolling, laminar cooling process and coiling, wherein the following process parameters are controlled: during the continuous casting process, the superheat range is 20-35 DEG C, the casting speed is controlled at the range of 0. 9-1.1 / min and strong cooling and large reduction are adopted in the solidification tail end; during the continuous casting process, a secondary cooling schedule is adopted for control and a cooling schedule in which the cooling speed of the front section is higher than that of the rear section in the secondary cooling section is adopted; during the heating process, a slab is heated to 1200-1240 DEG C in the heating furnace and the soaking time is greater than 180 minutes; during the finishing rolling process, the finishing rolling inlet temperature is 950 DEG C-990 DEG C and the finish rolling temperature is 800-840 DEG C; and during the coiling process, the target coiling temperature is 570 DEG C-590 DEG C.

Owner:SHOUGANG CORPORATION +1

Lanthionine derivatives

ActiveUS20120282386A1Function increaseEasy to prepareOrganic active ingredientsBiocideLanthionineChemistry

The present invention provides a variety of compounds having a CaSR agonist activity which possesses a superior kokumi-imparting function, and more particularly provides a kokumi-imparting composition, which contains the foregoing compound, and / or another substance having a CaSR agonist activity, in combination. The present invention also provides a kokumi-imparting composition which includes a lanthionine derivative and / or another substance having a CaSR agonist activity.

Owner:AJINOMOTO CO INC

Preparation method of nano-carbide intragranular strengthening type medium and high strength niobium alloy powder

The invention discloses a preparation method for a medium- and high-strength niobium alloy powder with an intracrystalline-strengthened nano-scale carbide. According to the method, NbC powder with a mass purity of greater than 99.95% and an average Fisher particle size of less than 3[mu]m is taken as a strengthening phase, the NbC powder and other alloy element powders are subjected to wet-millingand uniform mixing in a rolling ball-milling method, and then are dried, so that the medium- and high-strength niobium alloy powder with the intracrystalline-strengthened nano-scale carbide is obtained. According to the method, the NbC powder with a low particle size is adopted, the medium- and high-strength niobium alloy powder with the intracrystalline-strengthened nano-scale carbide is prepared through rolling ball-milling, and the carbide in a niobium alloy is subjected to second-phase refining and mostly distributed into crystals to form the nano-scale carbide, so that the strengtheningeffect of NbC is improved, then the strength of the niobium alloy is increased, the problem of difficulty to break and homogenize due to that a carbide is large in size and mostly distributed in a mesh shape along crystal boundaries, in a common preparation method for a niobium alloy with the strengthened carbide, is solved, and the insufficiency of the capacity of processing equipment is made up.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

A Corrosion Inhibitor for Preventing Corrosion of High-strength Low-alloy Steel in Chloride-Containing Corrosion Medium

InactiveCN106544679BInhibition of localized corrosionMitigate uniform corrosionRare-earth elementCerium nitrate

The invention provides a corrosion inhibitor capable of preventing high-strength low-alloy steel from being corroded in a chloride-containing corrosive medium and belongs to the field of inhibitors. The corrosion inhibitor comprises phosphate with the concentration being 300-600 ppm, sodium tripolyphosphate with the content being 200-400 ppm, sodium phosphate with the content being 100-200 ppm, a sodium nitrite compound with the concentration being 20-60 ppm and a cerium compound with the concentration being 30-80 ppm, wherein the cerium compound is cerium chloride, or cerium sulfate or cerium nitrate, and the valence state of cerium is +3. The corrosion inhibitor containing the rare earth element, namely cerium with the valence state being +3, is developed for preventing the high-strength low-alloy steel from being corroded in the chloride-containing corrosive medium so as to meet requirements of oceaneering and ship engineering in the ocean resource development process.

Owner:BEIJING UNIV OF CHEM TECH +1

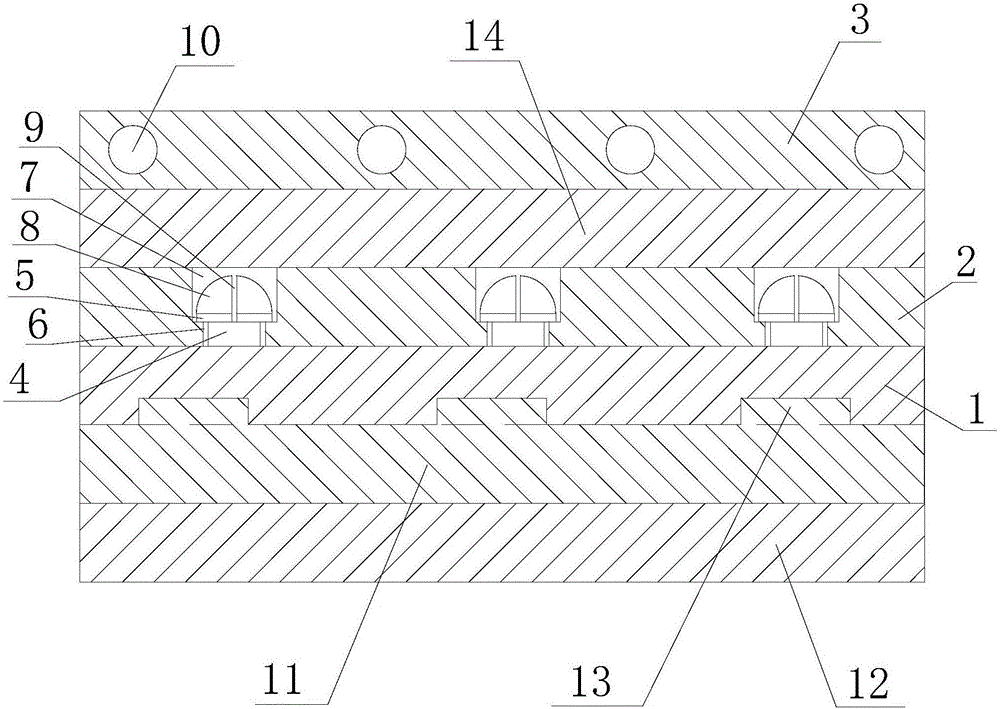

Low-impedance high-strength illuminating bus slot

InactiveCN108866361AHigh strengthImprove impact resistanceTotally enclosed bus-bar installationsEmbedded systemRare-earth element

The invention discloses a low-impedance high-strength illuminating bus slot, and relates to the technical field of electrical equipment. The bus slot comprises an upper cover plate, a lower cover plate, two side plates and a bus. A bus containing cavity is defined by the upper cover plate, the lower cover plate and the two side plates, the bus is arranged in the bus containing cavity, and the upper cover plate, the lower cover plate and the two side plates are each prepared from, by mass, 0.35-0.68% of C, 2.26-2.52% of Cr, 0.95-1.18% of Si, 0.66-0.73% of Zn, 2.34-2.58% of Cu, 0.13-0.18% of W,0.35-0.52% of Mn, 0.93-1.27% of Mg, 1.56-1.88% of rare earth elements and the balance Al and inevitable impurities. The strength of the low-impedance high-strength illuminating bus slot is higher thanthat of an existing bus slot, the bus impedance is low, energy can be saved, heat emitted during bus working is reduced, and the service life of the bus slot is effectively prolonged.

Owner:荣马电器有限公司

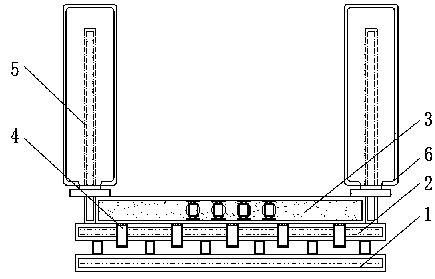

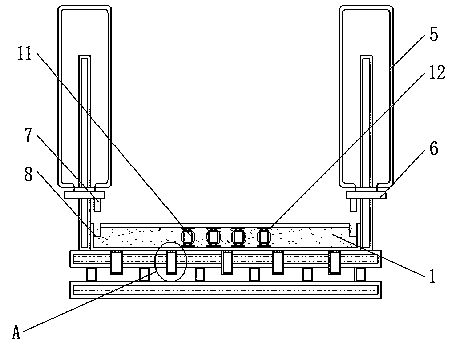

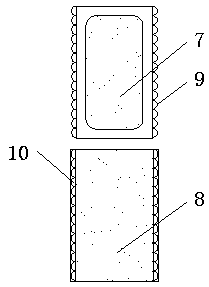

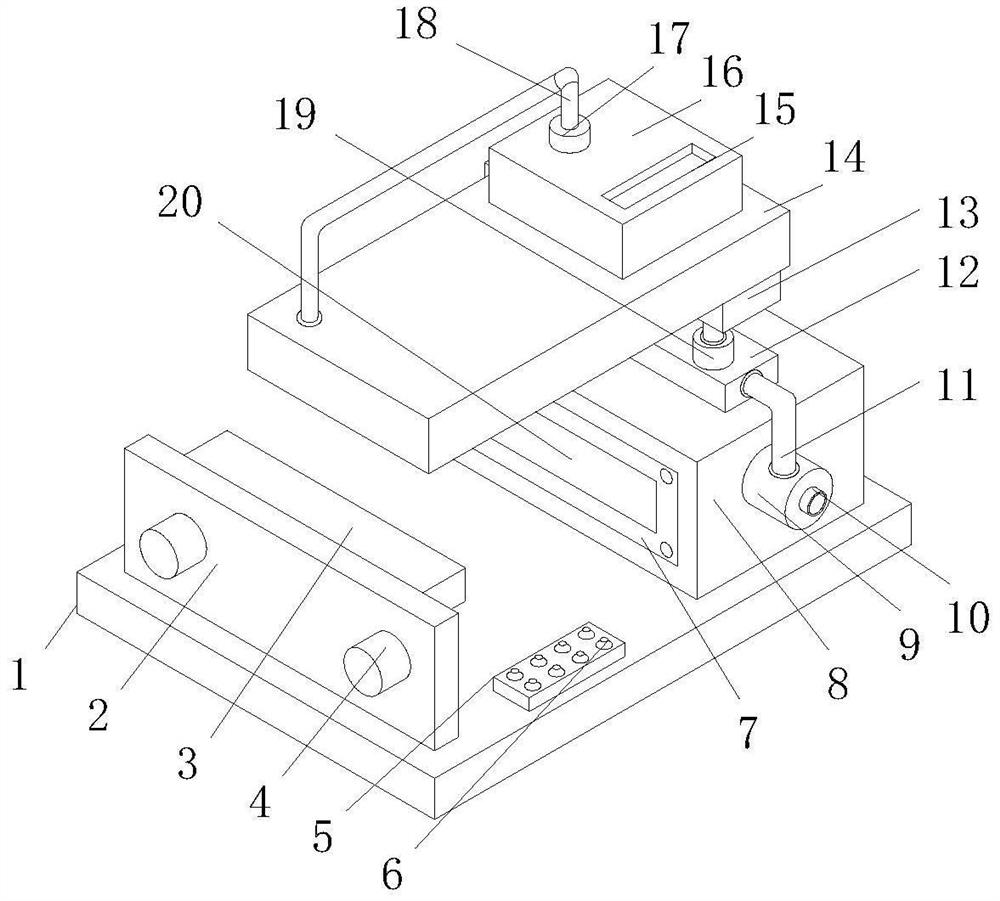

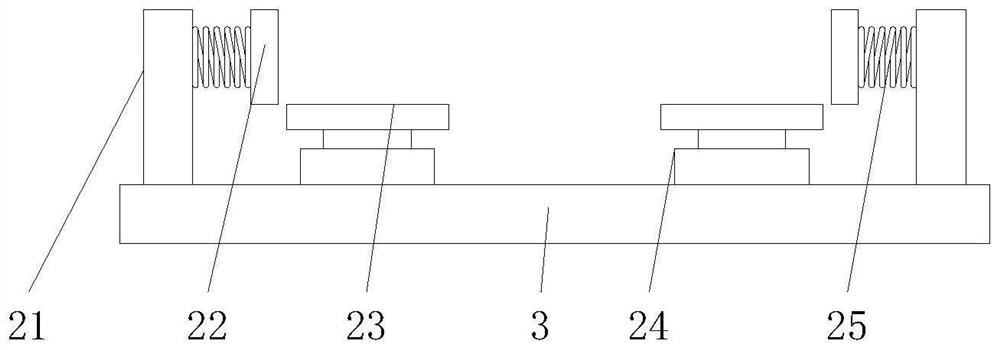

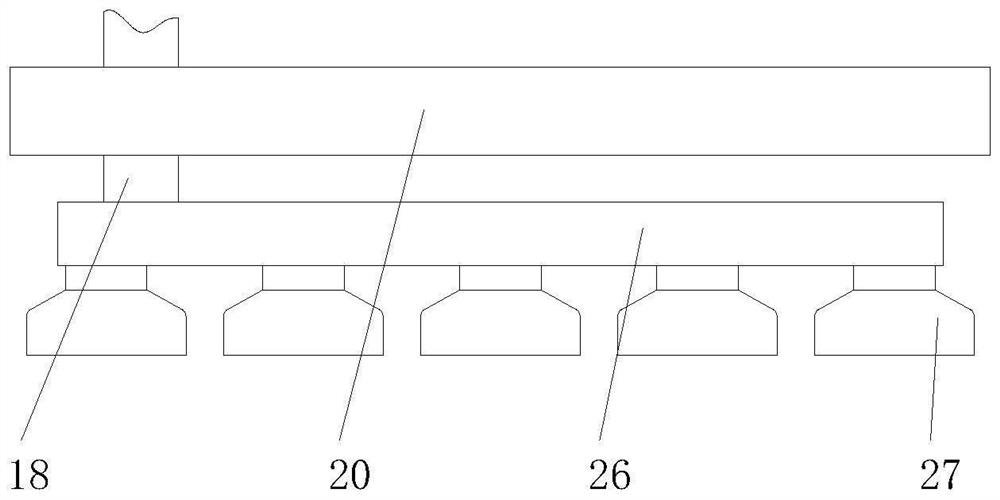

AR (Augmented Reality) layer strengthening equipment

InactiveCN114685060AImprove and strengthenIn the inner cavity of the strengthening box, accelerated by heatingPhysicsEngineering

The AR layer strengthening equipment comprises a bottom plate, a strengthening box is fixedly connected to the right side of the top of the bottom plate, mounting blocks are fixedly connected to the left and right sides of the upper and lower ends of an inner cavity of the strengthening box, heating rods are fixedly connected to the surfaces of the mounting blocks through bolts, and heating wires are arranged on the surfaces of the heating rods; a first fan is fixedly installed on the right side of the strengthening box, the output end of the first fan is fixedly connected with a first air conveying pipe, and the output end of the first air conveying pipe is fixedly connected with an exhaust plate. The right side of the top of the top plate is fixedly connected with a water tank, the left side of the top of the water tank is fixedly provided with a second fan, the output end of the second fan is fixedly connected with a second air conveying pipe, the output end of the second air conveying pipe is fixedly connected with an exhaust pipe, and the output end of the exhaust pipe is fixedly connected with an exhaust cover, so that the rapid cooling effect is achieved; therefore, the temperature of the glass can be quickly recovered to normal temperature, and the mechanical strength and thermal stability of the glass can be improved.

Owner:南京超晶光电新材料科技研究院有限公司

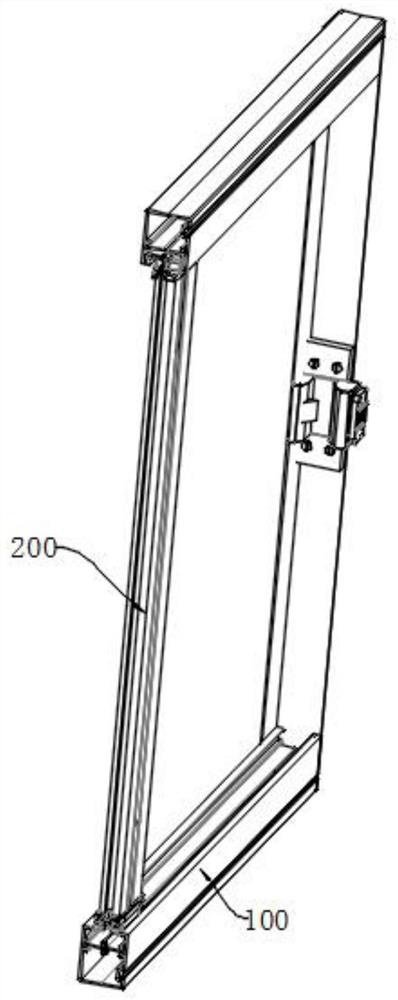

High-strength and light aluminum alloy door and window frame and preparation process thereof

ActiveCN113464020AFirmly assembledImprove assembly stabilityCorner/edge jointsFoundry mouldsEngineeringUltimate tensile strength

The invention discloses a high-strength and light aluminum alloy door and window frame. The high-strength and light aluminum alloy door and window frame is formed by sequentially assembling and connecting a transverse frame and a vertical frame, an assembling groove is formed in the transverse frame, a fixing base is fixedly connected to the end, connected with the transverse frame, of the vertical frame, a connecting sliding groove is formed in the lower portion of the side wall of the vertical frame, the transverse frame is further provided with a fixing sliding groove, and the fixing base at the bottom of the vertical frame is assembled in the fixing sliding groove in the transverse frame. The aluminum alloy door and window frame is high in stability after being assembled. In addition, the invention further discloses a preparation process of the aluminum alloy door and window frame. A MgZn2 strengthening phase and a CuAl2 strengthening phase are formed in an alloy material, so that the strength of the alloy material is greatly improved, and the design requirement of the material is met.

Owner:徐州华展门窗工程股份有限公司

Film coated pvc foam board

ActiveCN106273679BEasy to useImprove the indoor environmentSynthetic resin layered productsVehicle componentsUltimate tensile strengthIndustrial engineering

The present invention relates to a coated PVC foam board, solves the problem of the prior art can not PVC plates absorption of harmful gases. PVC foam sheet covered by the present invention, the activated carbon adsorption layer is provided on the foamed board, the activated carbon adsorption layer can absorb harmful gases, thereby optimizing the performance of PVC foam board, to improve the indoor environment; activated carbon adsorption layer connecting post, the stopper member is fixed to the foam board, the activated carbon adsorption layer also has a gas permeable layer, the activated carbon adsorption layer without removing the replacement block PVC foam board, the activated carbon adsorption layer only needs removal, replacement can, easy to operate; inlaid metal reinforcing web, the strength of the gas permeable layer, thereby improving the strength of the PVC foam board in the gas-permeable layer, is provided so that the pattern PVC foam board having a high connection strength at the installation , to optimize the performance of PVC foam board.

Owner:浙江通达塑业有限公司

A production method of steel for electric power pipe fittings and steel for electric power pipe fittings

The invention relates to the technical field of steelmaking and discloses a method for producing steel for pipe fittings and steel for the pipe fittings. The method comprises the following steps: smelting in a converter or an electric furnace, refining in an LF (ladle furnace) or RH vacuum treatment process, continuous casting, heating, rough rolling, finishing rolling, laminar cooling process and coiling, wherein the following process parameters are controlled: during the continuous casting process, the superheat range is 20-35 DEG C, the casting speed is controlled at the range of 0. 9-1.1 / min and strong cooling and large reduction are adopted in the solidification tail end; during the continuous casting process, a secondary cooling schedule is adopted for control and a cooling schedule in which the cooling speed of the front section is higher than that of the rear section in the secondary cooling section is adopted; during the heating process, a slab is heated to 1200-1240 DEG C in the heating furnace and the soaking time is greater than 180 minutes; during the finishing rolling process, the finishing rolling inlet temperature is 950 DEG C-990 DEG C and the finish rolling temperature is 800-840 DEG C; and during the coiling process, the target coiling temperature is 570 DEG C-590 DEG C.

Owner:SHOUGANG CORPORATION +1

Laminated PVC foam board

ActiveCN106273679AEasy to useImprove the indoor environmentSynthetic resin layered productsVehicle componentsUltimate tensile strengthIndustrial engineering

The invention relates to a laminated PVC foam board, solving the defect that a PVC board cannot adsorb harmful gases in the prior art. An active carbon adsorption layer is arranged on the foam board and can adsorb harmful gases, thereby optimizing the use performance of the PVC foam board and improving the indoor environment. The active carbon adsorption layer is fixed on the foam board through connecting columns and limiting stoppers. The active carbon adsorption layer is further provided with a breathable layer. During change of the active carbon adsorption layer, dismounting of the entire PVC foam board is not required, and only the active carbon adsorption layer needs to be dismounted for change, and the operation is quite convenient. A metal reinforcement net is inlaid in the breathable layer to increase the strength of the breathable layer, so that the strength of the PVC foam board is improved. The arrangement of patterns allows the PVC foam board to have high connection strength during installation, and the use performance of the PVC foam board is optimized.

Owner:浙江通达塑业有限公司

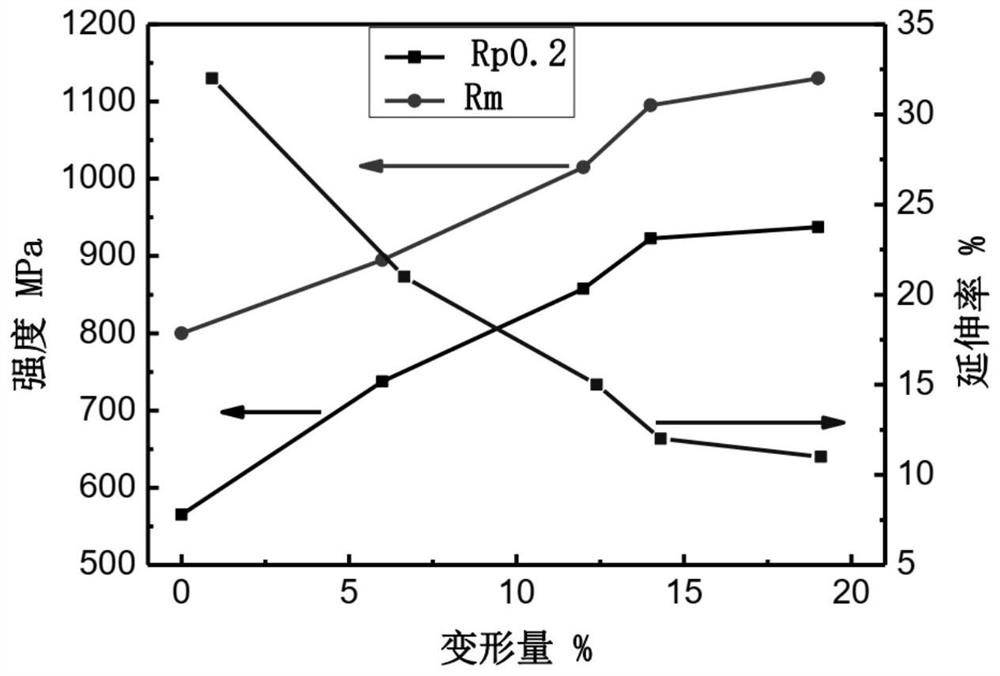

Economical duplex stainless steel plate, method for improving strength of economical duplex stainless steel plate and application of economical duplex stainless steel plate

The invention belongs to the field of special stainless steel variety development and application, and particularly relates to an economical duplex stainless steel plate, a method for improving the strength of the economical duplex stainless steel plate and application of the economical duplex stainless steel plate. The method for improving the strength of the economical duplex stainless steel plate comprises the following steps: (1) carrying out first solution treatment on a duplex stainless steel hot-rolled coiled plate, and carrying out water cooling after discharging; (2) after cold rolling to a target thickness, carrying out second solution treatment; (3) the duplex stainless steel is strengthened through cold machining; and (4) the economical duplex stainless steel plate product is obtained through flattening and withdrawal and straightening. According to the method, further high strengthening of the economical duplex stainless steel cold plate is achieved, meanwhile, the strength and the ductility of a finished product are reasonably matched (Rp0.2 is larger than or equal to 630 MPa, and the ductility A50 is larger than or equal to 20%), and an ideal stainless steel material solution is provided for light weight of a vehicle body bearing structure.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

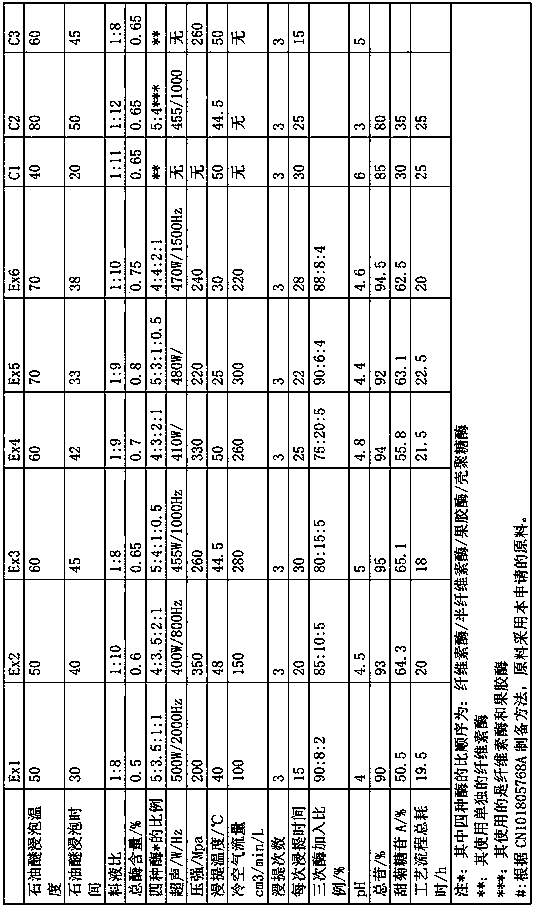

Novel method for extracting stevioside efficiently and quickly

InactiveCN111153949ASpeed up the extraction processReduce processing timeSugar derivativesSugar derivatives preparationPectinaseSteviolmonoside

The invention relates to a novel method for extracting stevioside efficiently and quickly. The novel method comprises the following steps of (1) drying stevia rebaudiana leaves, performing crushing, and performing screening with a 100-200-mesh sieve; (2) then performing soaking in petroleum ether under the stirring condition of 50-70 DEG C for 30-45min; (3) after filtration, performing leaching treatment on filtered substances in a sodium citrate solution which contains complex enzymes and of which the pH is 4-5, wherein the complex enzymes are cellulase / hemicellulase / pectinase and chitosan enzymes, the proportion of the four complex enzymes is (4-5) to (3-4) to (2-1) to (1-0.5), the ratio of the filtered substances (by weight) to a solvent namely water is 1 to (8-10), the content of the complex enzymes in a leaching solution is 0.5%-0.8%, the leaching temperature is 20-55 DEG C, leaching is performed for three times, the leaching time each time is 10-20min, an enzyme adding manner isa step progressively-decreased adding manner, during leaching, leaching equipment is used for performing leaching under high pressure, the intensity of pressure is set to be 200-350Mpa, during leaching, ultrasonic strengthening is adopted, the ultrasonic power is 400-500W, the frequency is 100-2000Hz, cold air is charged into the leaching solution, the flow of the cold air is calculated by using each volume of solutions to be extracted as the standard, and 100-300cm<3> / min is needed; and (4) adding a flocculant, performing a flocculation reaction, then performing filtration, performing decolorization, performing concentration and performing crystallization.

Owner:内蒙古昶辉生物科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com