Lightweight fulcrum bar of headrest of automobile

A car headrest and lightweight technology, which is applied to vehicle seats, vehicle parts, special positions of vehicles, etc., can solve the problems of material waste, high cost, and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

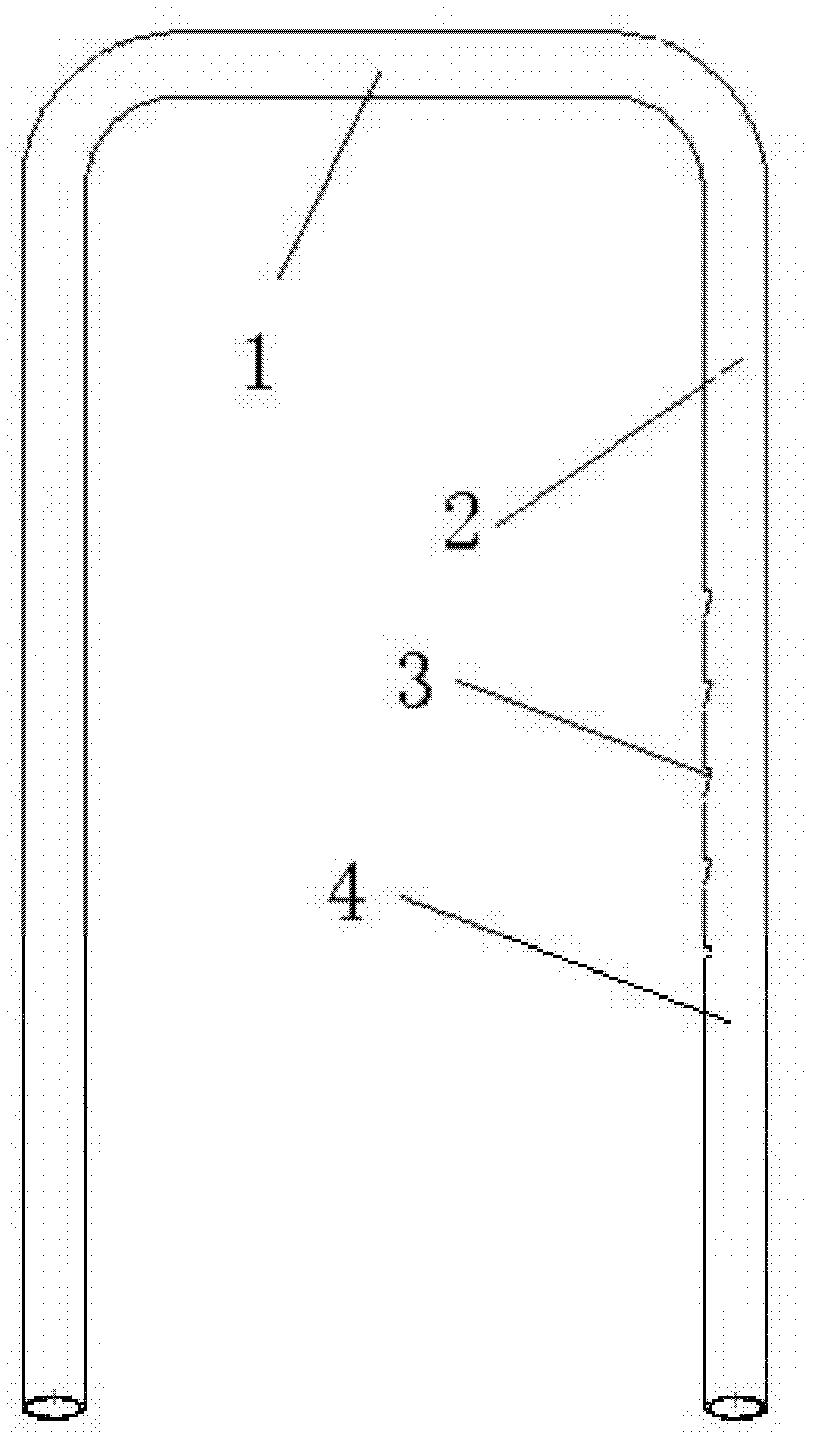

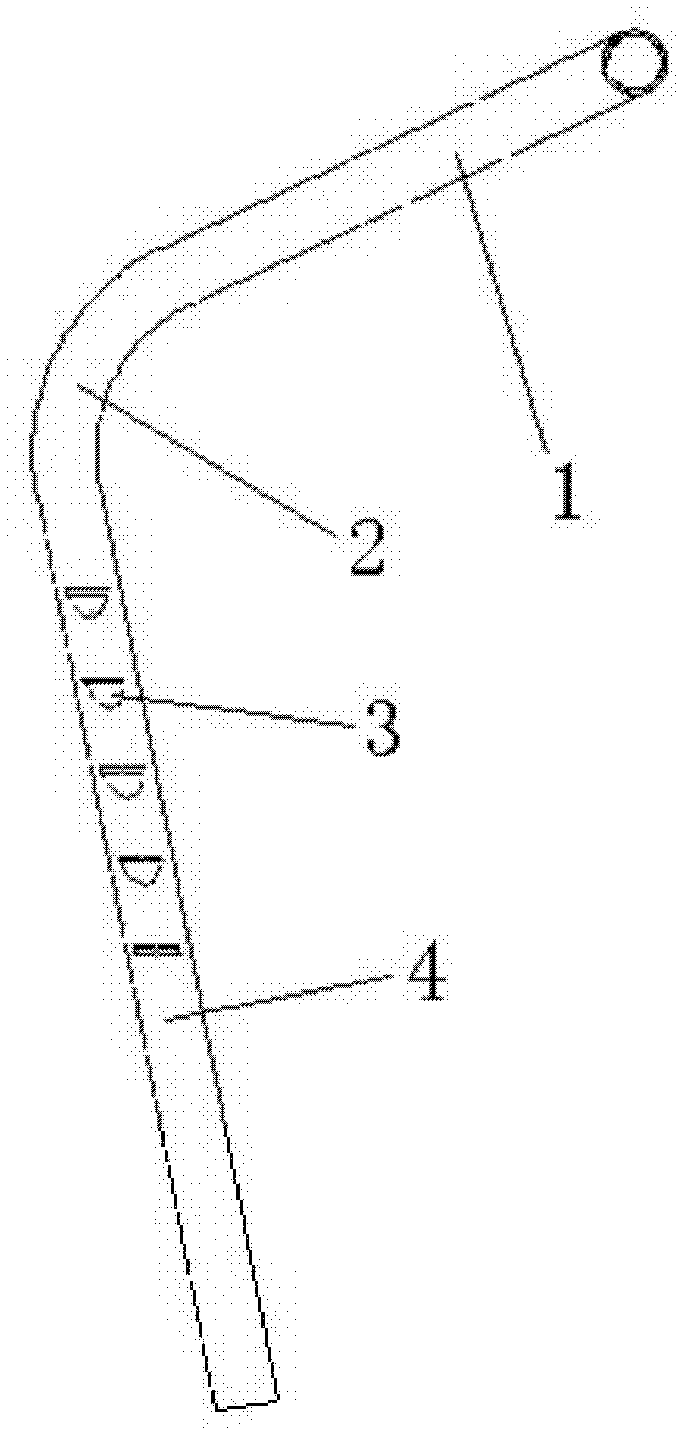

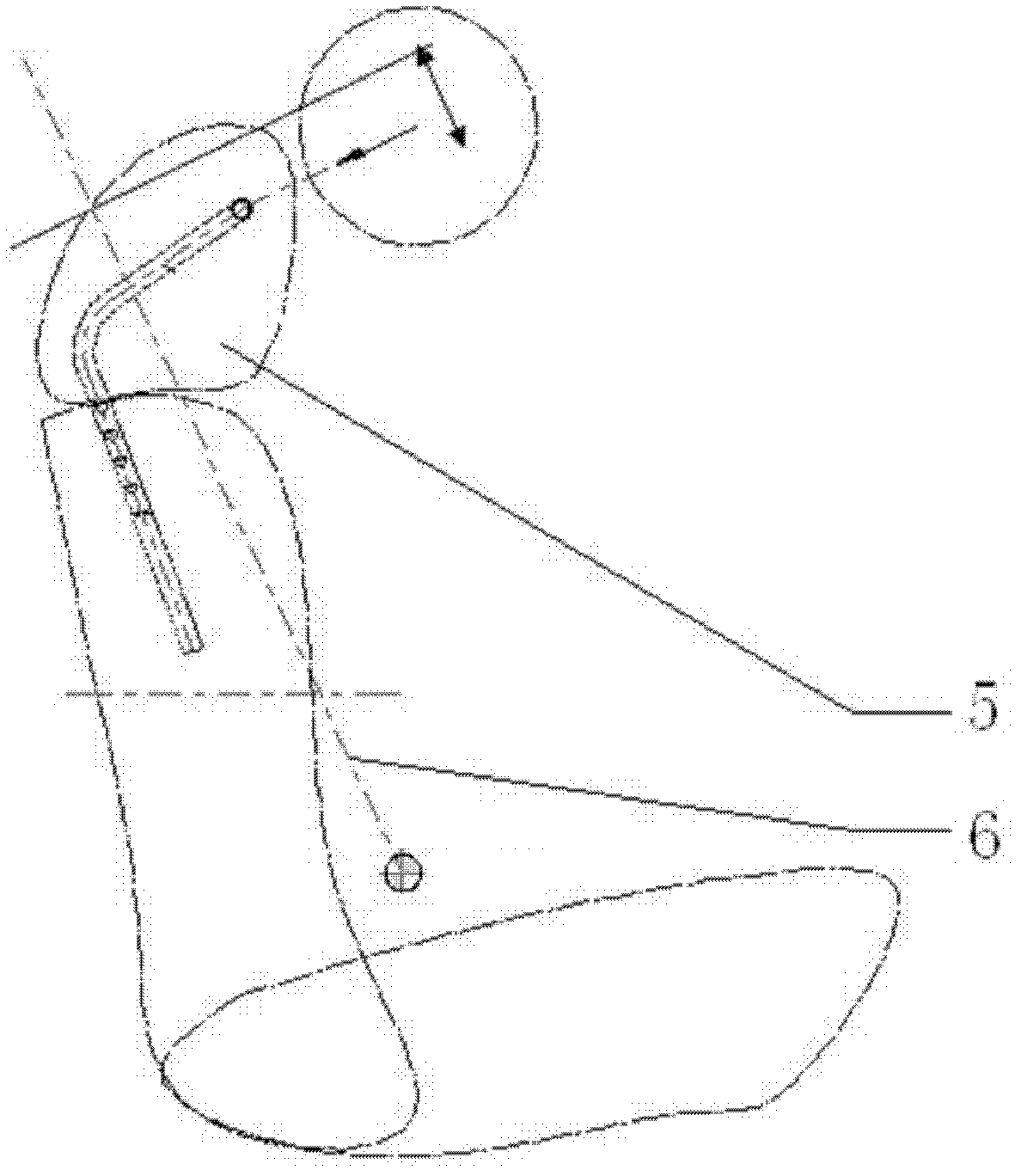

[0017] Install the headrest pole on the headrest of the car, wherein the supporting part 1 and the connecting part 2 are inside the headrest 5, and the adjustment guide part 4 is exposed on the lower part of the headrest, and the supporting part 1 is installed on the top of the headrest 5 At a distance of 65mm, insert the adjustment guide part 4 of the headrest strut parallel to the seat trunk line 6 into the guide sleeve of the chair back, and adjust the groove 3 to clamp the headrest strut into the guide sleeve of the chair back.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com