A production method of steel for electric power pipe fittings and steel for electric power pipe fittings

A production method and technology for pipe fittings, applied in the field of steel for electric power pipe fittings and steel for electric power pipe fittings, can solve the problems of good plastic toughness, inability to produce strength, and low manufacturing cost, so as to improve safety and reduce the total amount of steel used , the effect of good elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

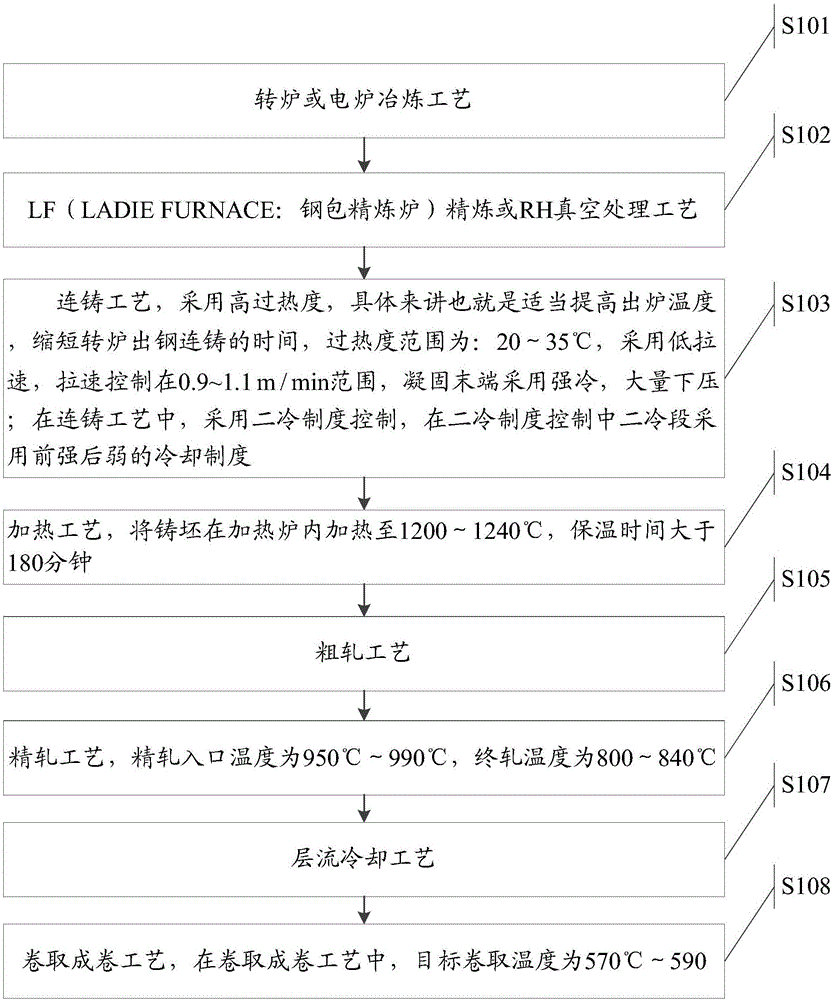

Method used

Image

Examples

Embodiment 1

[0061] The 220 tons of molten steel smelted in a converter and refined outside the furnace are continuously cast into billets, and the weight percentages are C: 0.16%, Si: 0.13%, Mn: 0.59%, P: 0.012%, S: 0.004%, Al: 0.042%, Ti: 0.08%, N: 0.004%, and the rest are Fe and unavoidable impurities. The thickness of the slab is 230mm.

[0062] Rolling is carried out in the 1580 hot continuous rolling production line, the heating temperature is 1210°C, the finish rolling entrance temperature is 970°C, the final rolling temperature is 820°C, the target thickness is 6mm, and after rolling, it is cooled to the target coiling temperature of 590 by laminar cooling. ℃, air-cooled to room temperature after coiling.

[0063] The yield strength Rel of the high-strength steel produced according to the above method is 465MPa, the tensile strength is 550MPa, the elongation is 26%, and the cold bending D=1.5a has no cracks on the surface (D is the diameter of the bending core, a is the thickness ...

Embodiment 2

[0065] The molten steel smelted in a 220-ton converter and refined outside the furnace was continuously cast into a slab, and its weight percentage was the same as in Example 1. The thickness of the slab is 230mm.

[0066] Rolling is carried out in the 1580 hot continuous rolling production line, the heating temperature is 1240°C, the finish rolling entrance temperature is 990°C, the final rolling temperature is 840°C, the target thickness is 4mm, after rolling, it is cooled by laminar flow to the target coiling temperature of 570°C , and air-cool to room temperature after coiling.

[0067] The yield strength Rel of the high-strength steel produced according to the above method is 470MPa, the tensile strength is 565MPa, the elongation is 24%, and there is no crack on the surface of the cold-formed D=1.5a.

Embodiment 3

[0069] The molten steel smelted in a 220-ton converter and refined outside the furnace was continuously cast into a slab, and its weight percentage was the same as in Example 1. The thickness of the slab is 230mm.

[0070] Rolling is carried out in the 1580 hot continuous rolling production line, the heating temperature is 1200°C, the finish rolling entrance temperature is 960°C, the final rolling temperature is 800°C, the target thickness is 8mm, and after rolling, it is cooled by laminar flow to the target coiling temperature of 590°C , and air-cool to room temperature after coiling.

[0071] The yield strength Rel of the high-strength steel produced according to the above method is 465MPa, the tensile strength is 545MPa, the elongation is 23%, and there is no crack on the surface of the cold-formed D=1.5a. -20°C Charpy impact absorption energy is 86J (sample size 5*10*55mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com