A kind of deformation heat treatment method of mg-al system precipitation strengthened magnesium alloy

A technology of deformation heat treatment and precipitation strengthening, which is applied in the field of metal strengthening and toughening, can solve the problems of difficult deformation path, insufficient research, difficult control of dislocation and twin distribution, etc., and achieve the goal of weakening anisotropy and improving strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

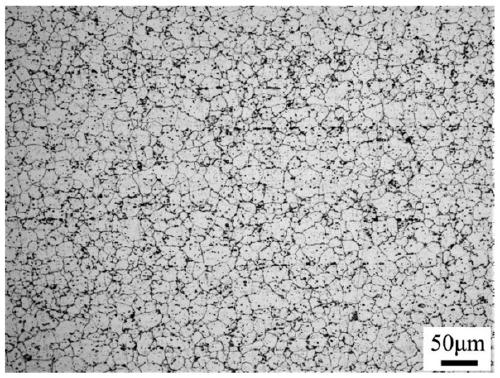

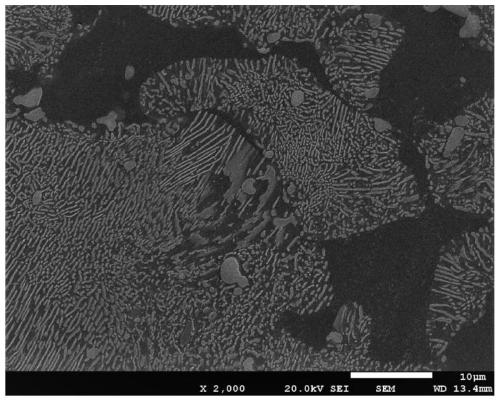

[0047] The billet used is cut from the Mg-8Al-0.5Zn-0.25Mn (AZ80) magnesium alloy extruded rectangular bar, its cross-sectional size is 230mm×140mm, the billet size is 230mm×140mm×500mm, and the average grain size of the billet is about 16 μm, such as figure 1 shown. The service conditions require that the yield strengths of the blanks ED and ND are both greater than 200MPa. After direct double-stage aging treatment of the billet at 140°C / 10h+170°C / 24h, the room temperature tensile properties of ED and ND are shown in Table 1 (the sample is taken from the surface layer of the rectangular material). It is found from Table 1 that the rectangular material has significant anisotropy, the yield strength in the ED direction is high, and the yield strength in the ND direction is low, which cannot meet the service requirements. The root cause of the poor aging strengthening effect is that the discontinuous precipitates dominate. Such as figure 2 shown. Therefore, adopt the deforma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| deformation temperature | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com